Disclaimer: I did not do the port work on this saw!!!

A quick history here. This 3120 was bought brand new back in '04 by another forum member. It was ported, muffler modded, and the timing advanced. Shortly there after the offset keyway sheared. It hasn't run right since that time and has just sat all these years. I have it to sort it out and get it running good. I pulled a compression check and only got 110-115 PSI. However, the rings still look like brand new, with the little machine lines still in them. This saw never even got broken in.

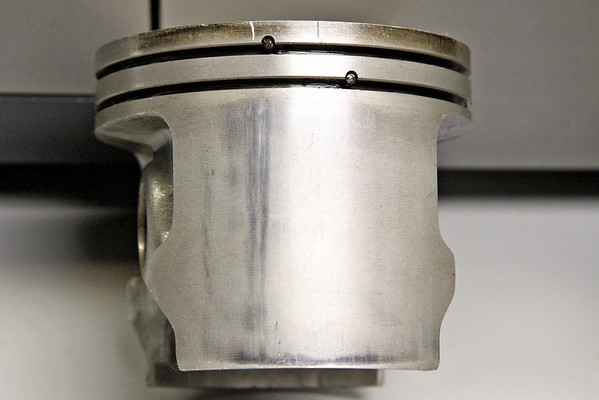

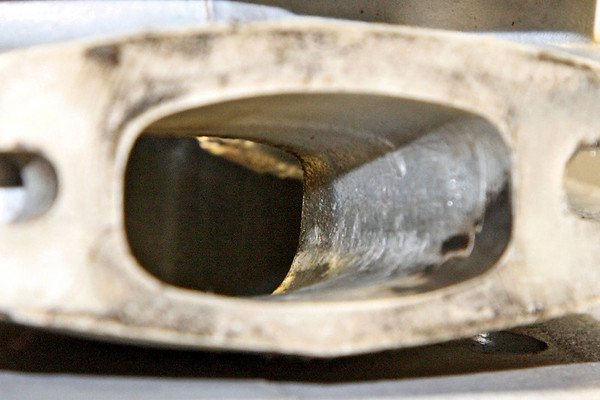

None of the ports were widened. However, the exhaust was raised A LOT. The transfers were also raised considerably, and the intake lowered. I will be putting a degree wheel on it to see where it sets.

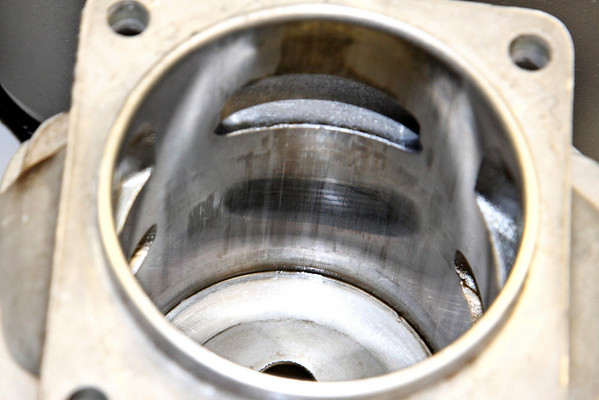

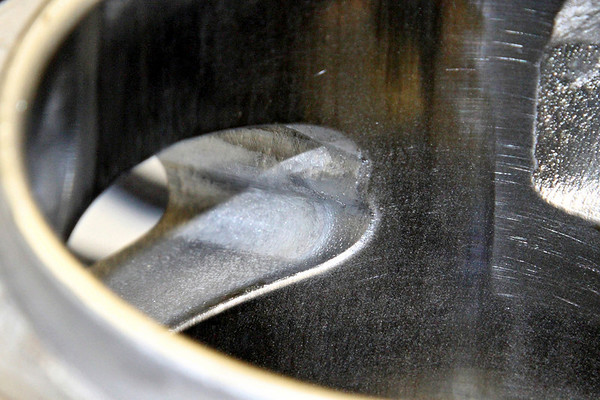

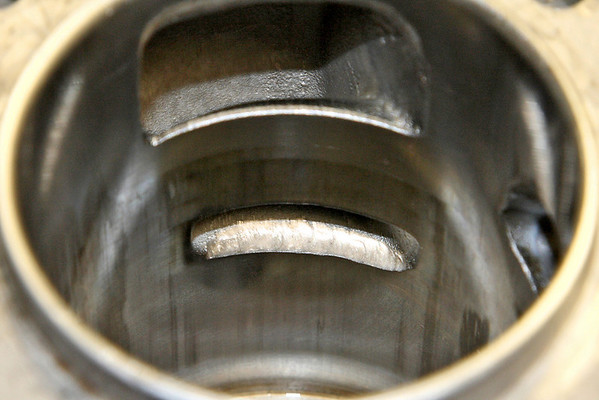

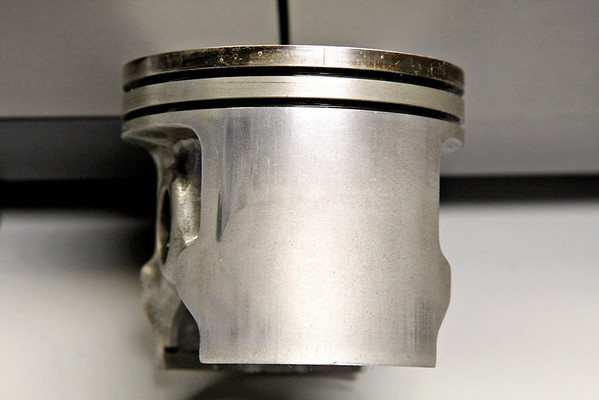

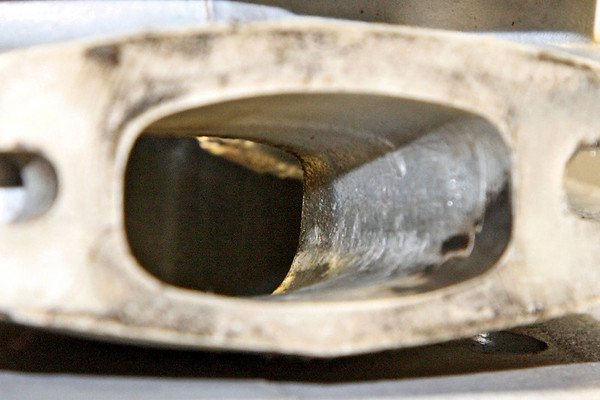

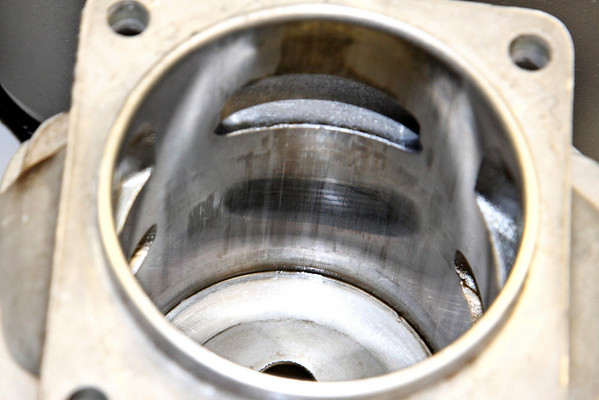

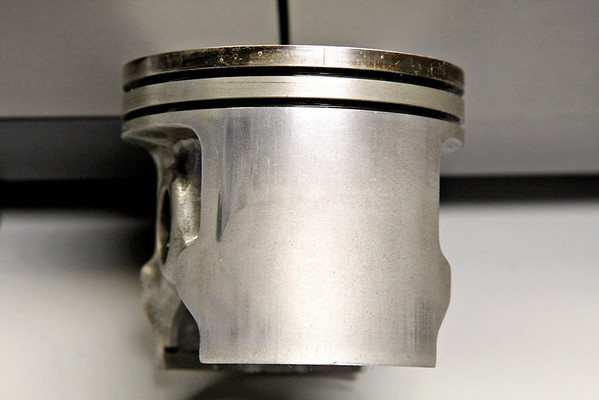

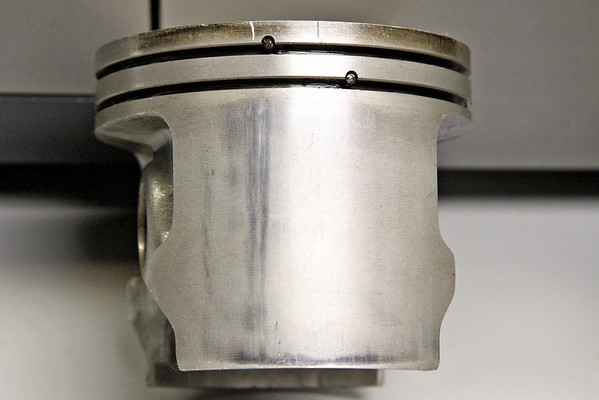

What happened to this saw? Notice all the odd markings in the cylinder and piston. Did this saw get real hot at one time, but not enough to seize? You can see the shape of the exhaust port roof on the piston skirt where the piston is at TDC. Was the port not deburred and beveled after porting, and marked the piston? There's one line to the right of the exhaust port on the cylinder wall that I can feel. Why is the compression so low? Exhaust too high?

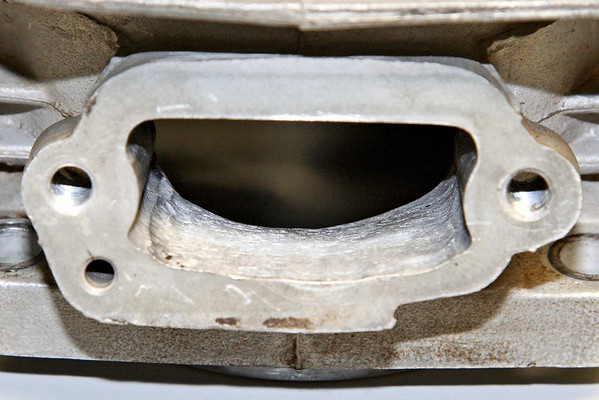

It was only raised at the cylinder wall, and not tapered out to the flange.

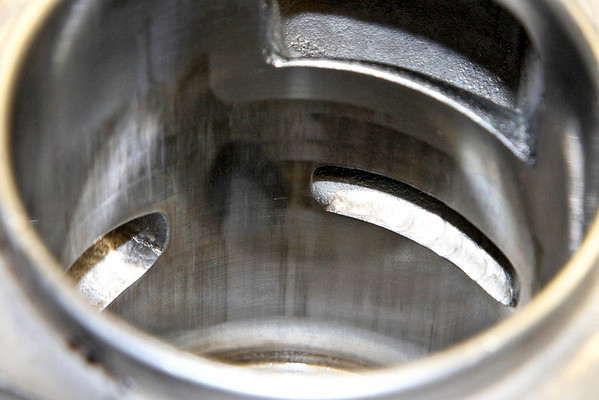

Not widened at the cylinder wall at all. You see some finish sanding marks towards the flange. It was not widened.

Markings above the intake.

A quick history here. This 3120 was bought brand new back in '04 by another forum member. It was ported, muffler modded, and the timing advanced. Shortly there after the offset keyway sheared. It hasn't run right since that time and has just sat all these years. I have it to sort it out and get it running good. I pulled a compression check and only got 110-115 PSI. However, the rings still look like brand new, with the little machine lines still in them. This saw never even got broken in.

None of the ports were widened. However, the exhaust was raised A LOT. The transfers were also raised considerably, and the intake lowered. I will be putting a degree wheel on it to see where it sets.

What happened to this saw? Notice all the odd markings in the cylinder and piston. Did this saw get real hot at one time, but not enough to seize? You can see the shape of the exhaust port roof on the piston skirt where the piston is at TDC. Was the port not deburred and beveled after porting, and marked the piston? There's one line to the right of the exhaust port on the cylinder wall that I can feel. Why is the compression so low? Exhaust too high?

It was only raised at the cylinder wall, and not tapered out to the flange.

Not widened at the cylinder wall at all. You see some finish sanding marks towards the flange. It was not widened.

Markings above the intake.