The HDB's are easy to kit. Just make sure when you remove the metering plate to replace the gasket under it you note which gasket it is. The kits come with two which are different.

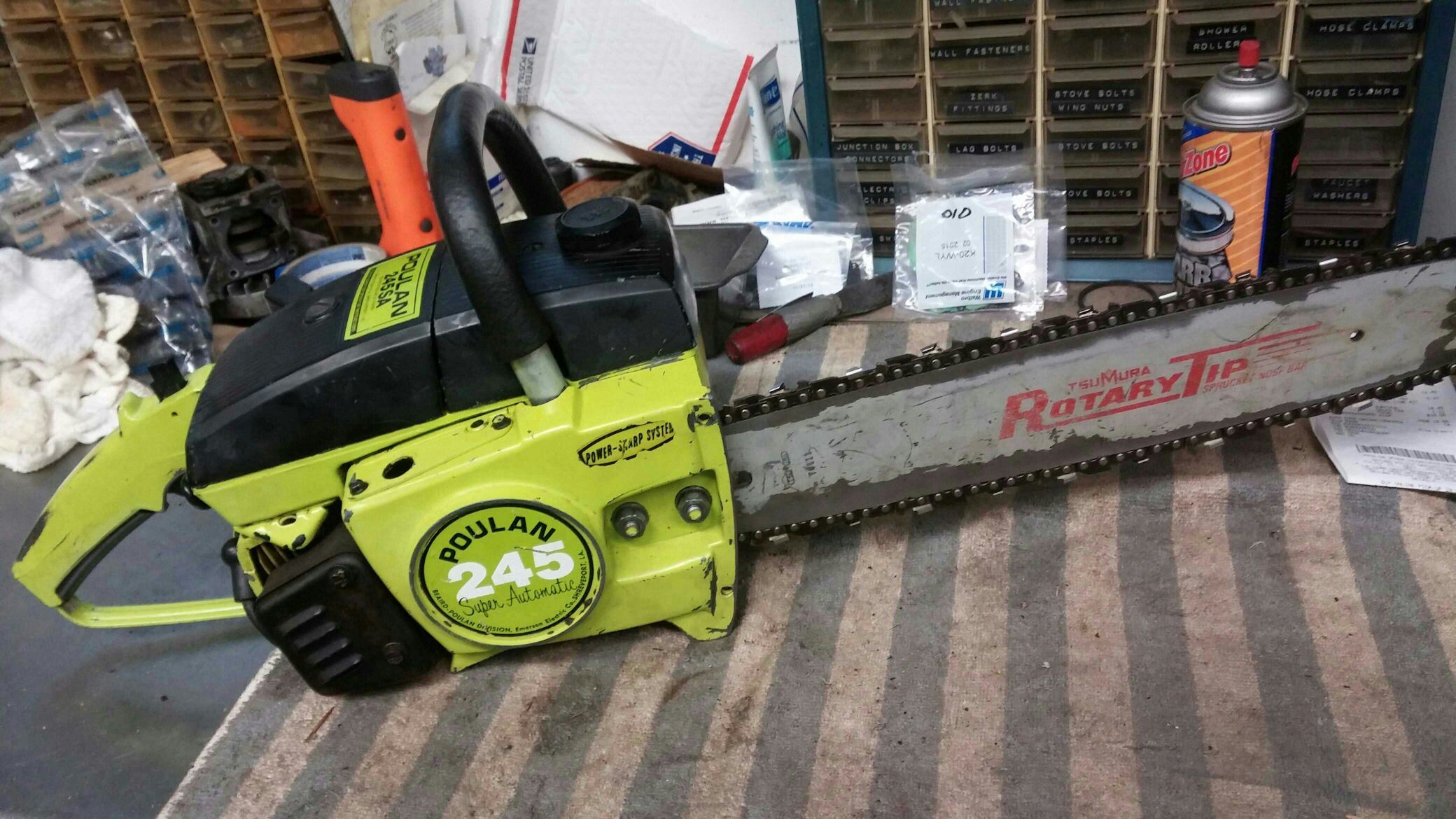

Compression is generally low on those saws and should read between 125 and could be as high as 140 but are usually in the 135 range. They are a very dependable saw and cut quite fast.

Since it has an impulse oiler, there is a hole into the case behind the oiler. It doesn't hurt to plug that off if you can't find any obvious air leaks. I've had ones that hold well without blocking that hole off and ones that didn't.

If the SKF 6119 seal is not available, a National (Timken) 253747 is the same. Both sides use the same seal. I like the SKF 6119's as they are a little easier to get in. The seal case on the National seals run a few thou larger in diameter.

There is a step on the crank on the PTO side. I use a piece of 1/2" copper pipe to help get the seal over the lip. Tape or other stuff works as well.

Service manual here. Good manual and fairly short.

https://app.box.com/s/326l10jokbvaqxudjbr0

HDB explosion here.

http://wem.walbro.com/walbro/product2.asp?Series=HDB&partnum=HDB-8-1