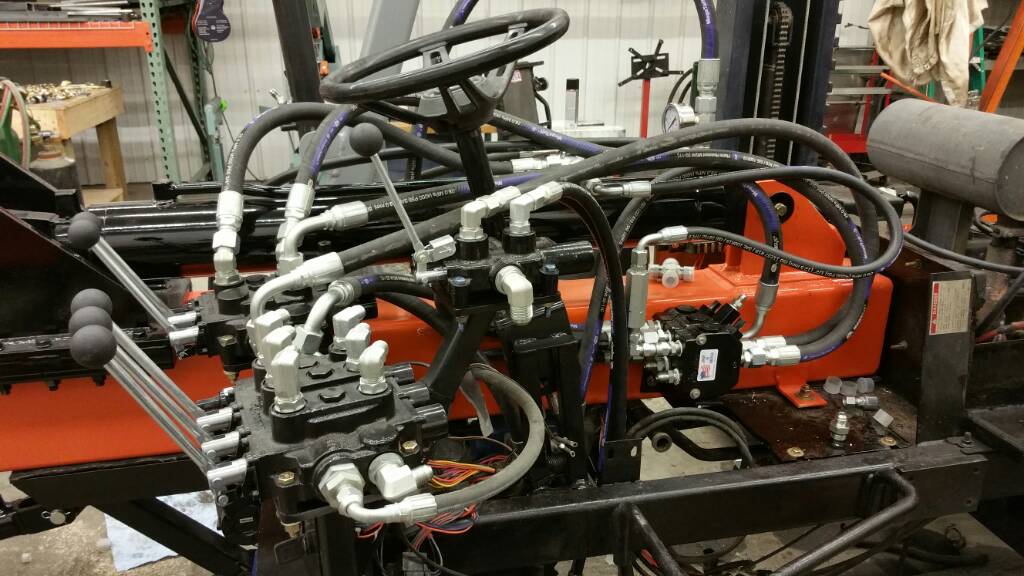

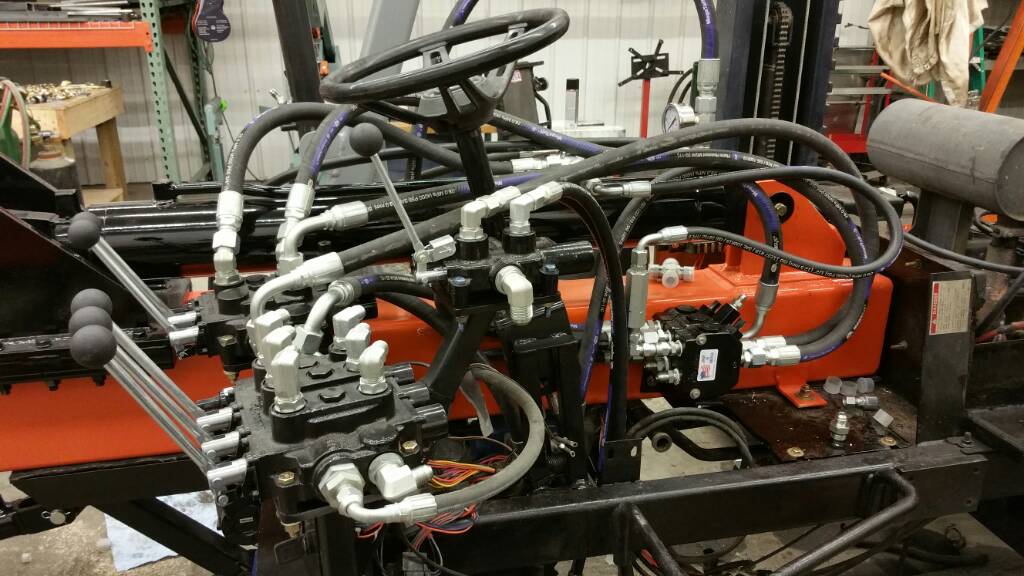

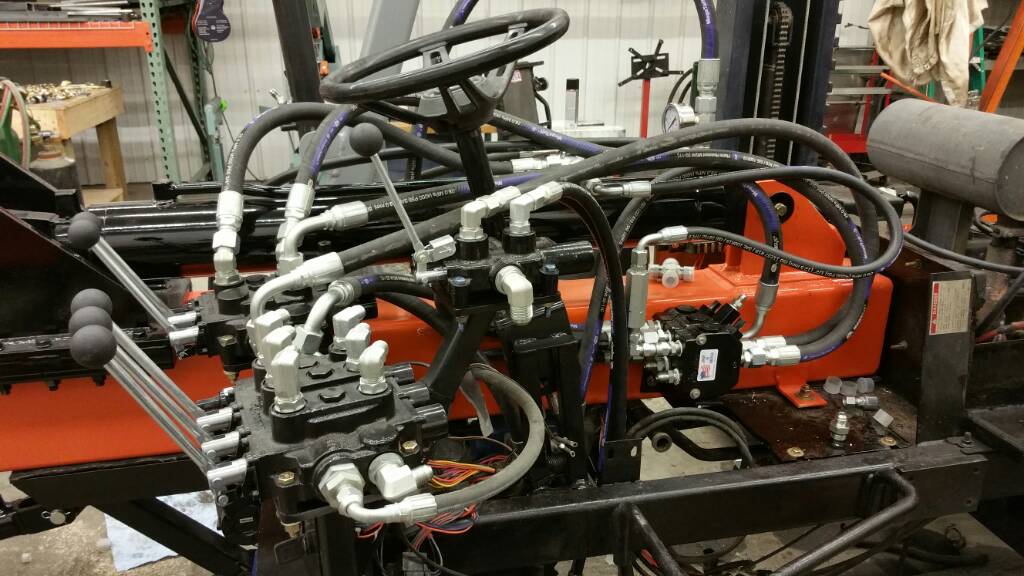

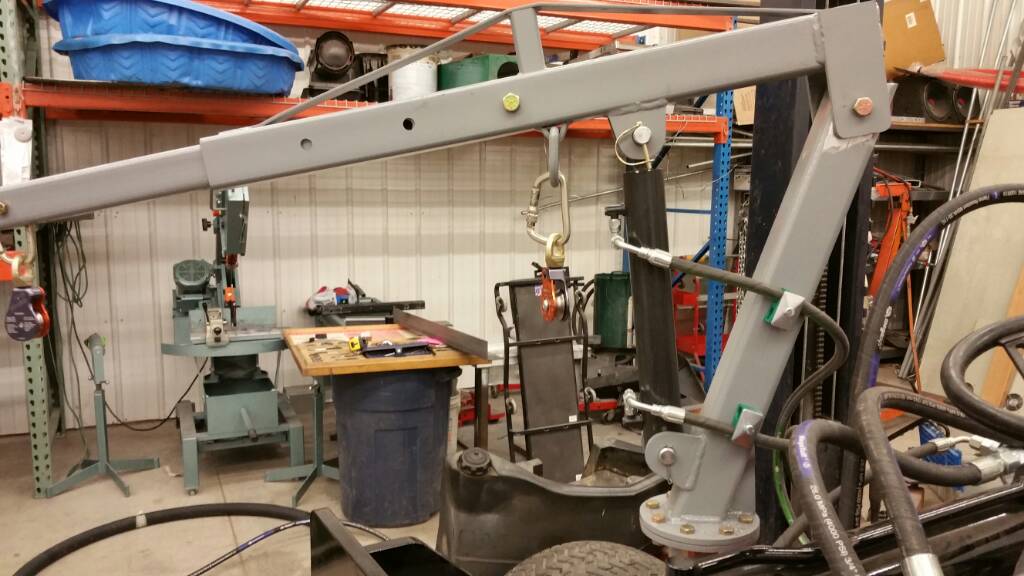

Still more hoses to install.

Getting closer.

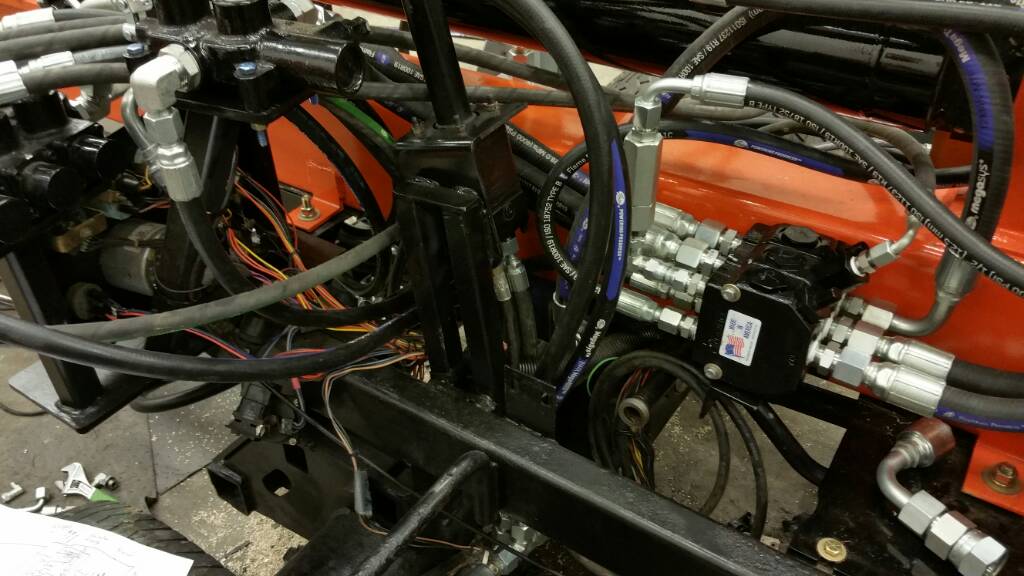

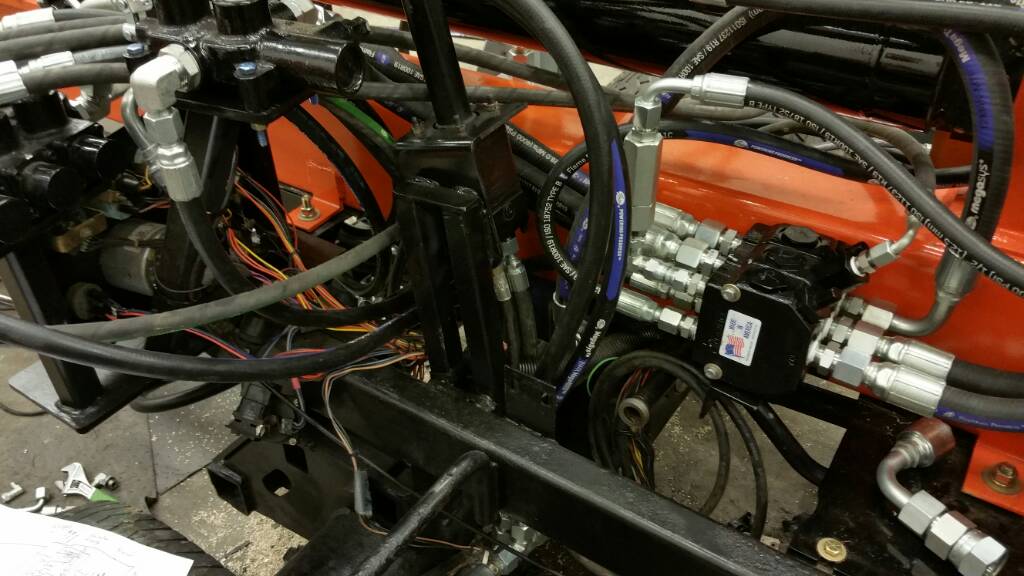

Waiting for manifold to come UPS

What is the thing all the hoses are going to in this pic (that I quoted, I didn't include all the other pics)? I can see 9 hoses from from it, and I know there are more. What's that for or what's is function?

Loose but not loose enough. Good call!Sam: You may want to loosen the hose clamps on the boom until you know how much the cylinder is going to move. I just replaced several hoses on my forklift. When checking for leaks, I realized I could have easily ripped a fitting out of a cylinder for lack of hose play. Side note: It's almost time to get the swimming pools out.

View attachment 502549 View attachment 502550 View attachment 502552 View attachment 502553

Kids!

Enter your email address to join: