BigOakAdot

ArboristSite newb

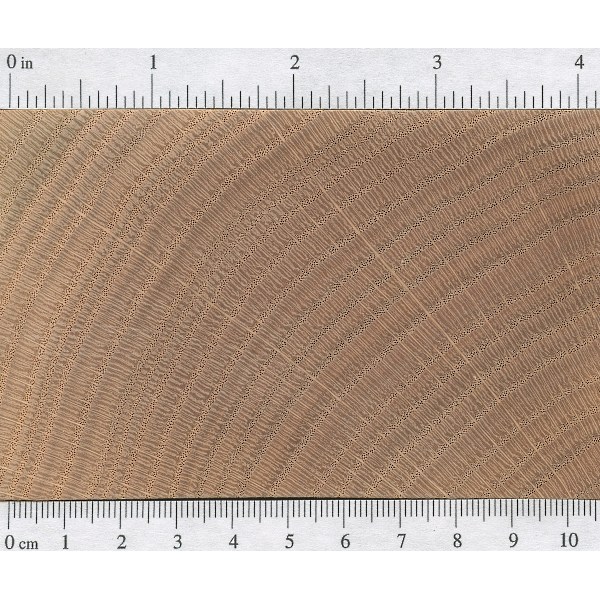

I just got a really nice cherry cookie flattened on my router sled. It took way longer than anticipated because it had warped so severely.

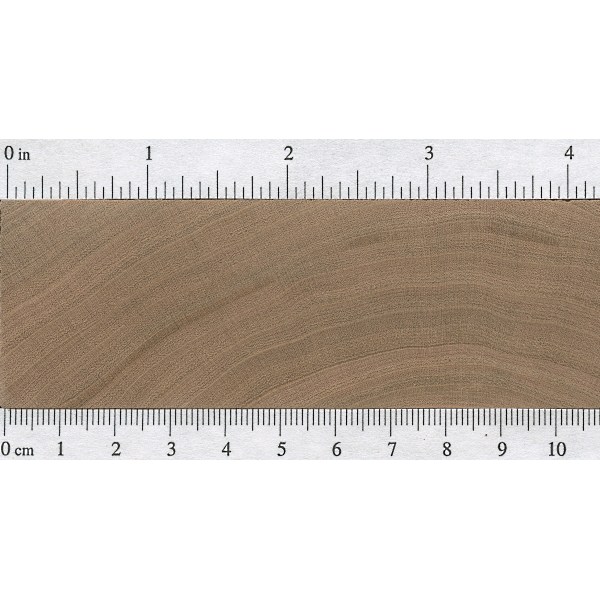

I just got a really nice cherry cookie flattened on my router sled. It took way longer than anticipated because it had warped so severely. I'm kicking myself for not just re sawing it now that it's fairly dry. After getting the top completely flat it left some parts of the cookie thicker due to the warping on the underside.

If you were to resaw the bottom to give it and even thickness would you use regular cross cutting chain? Would ripping chain leave a smoother surface? I'm not too concerned with the bottom because the coffe table will sit low. Just want it finished already!!

Thanks!

BOA