Wife'nHubby

Addicted to ArboristSite

Well, Jon1270, maybe I should subscribe to the train of thought of laziness on the part of the seller as you indicated. Apparently they don't have a digital camera/phone to take their own picture. They do not believe in "Truth in Advertising" because this is NOT their splitter. They state 5 hp B&S and 19 inches splits. Wrong. The splitter pictured (mine) has a slightly larger than 5 hp B&S and I can split longer than their stated 19".

So.......... I sent the seller a <kindly> reminder of Craigslist rules which are photos included must be of the <exact> item for sale. They have updated their photos:

Didier had about 4 different models. Their 'For Sale" model is a smaller version of what I own.

So.......... I sent the seller a <kindly> reminder of Craigslist rules which are photos included must be of the <exact> item for sale. They have updated their photos:

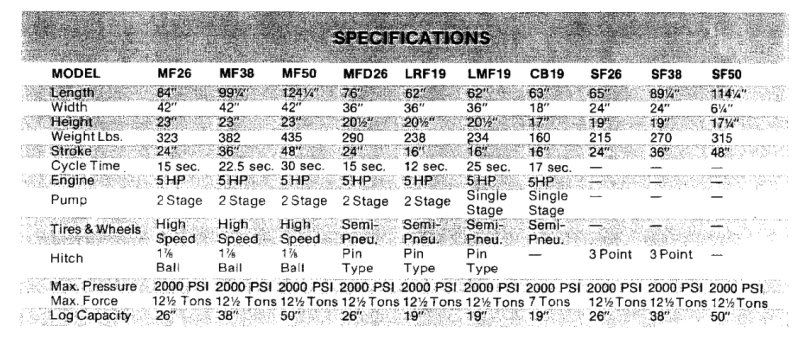

Didier had about 4 different models. Their 'For Sale" model is a smaller version of what I own.