Moddoo

ArboristSite Operative

Hello all.

Not a chainsaw, but small 2 stroke anyway.

I picked up this snowblower for $20 this summer.

Cleaned the carb, and it runs great.

Then today I decided to tear it down for the heck of it and see how it's built.

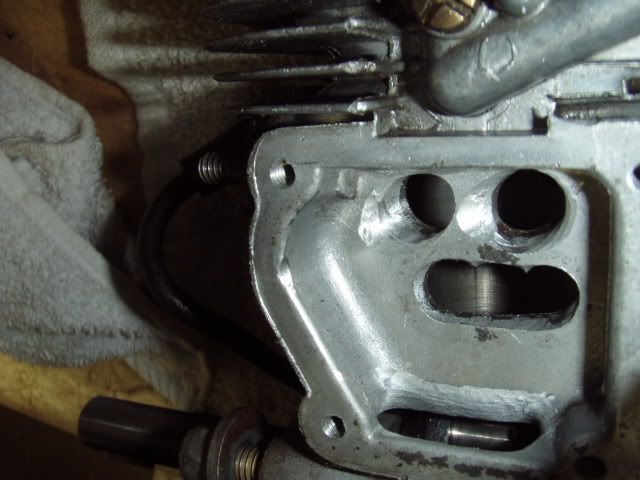

I find that the ports are simple drill holes in the jug.

The transfers from the case to the intakes are uncleaned cast openings.

And the head gasket is thick paper.

I plan on cleaning up the transfers and shaping the port "mouths" to promote better flow.

The exhaust pipe needs a lot of work near the port to remove the 'wall' it creates at the gasket.

Also thinking of ditching the head gasket or using a thinner one to increase compression. I may do some math and measuring to determine how far to go with this.

I don't plan on changing port timing at all at this time. Since I am unsure of where to go with it.

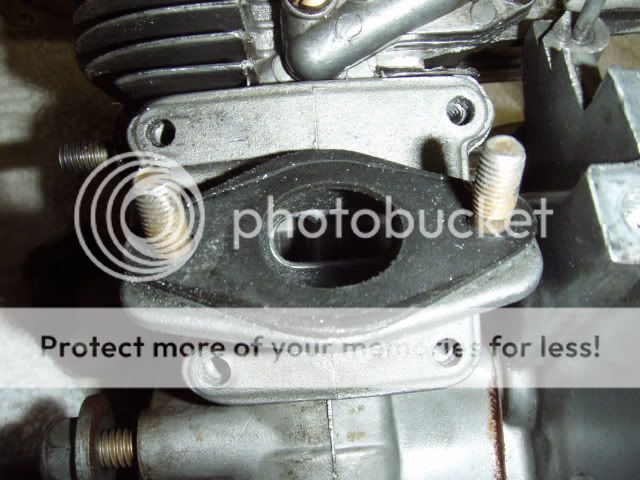

I may decrease the volume in the intake manifold where it creates a transfer port on that side.

Anyone else ever mess with one of these little snow throwers before?

Not a chainsaw, but small 2 stroke anyway.

I picked up this snowblower for $20 this summer.

Cleaned the carb, and it runs great.

Then today I decided to tear it down for the heck of it and see how it's built.

I find that the ports are simple drill holes in the jug.

The transfers from the case to the intakes are uncleaned cast openings.

And the head gasket is thick paper.

I plan on cleaning up the transfers and shaping the port "mouths" to promote better flow.

The exhaust pipe needs a lot of work near the port to remove the 'wall' it creates at the gasket.

Also thinking of ditching the head gasket or using a thinner one to increase compression. I may do some math and measuring to determine how far to go with this.

I don't plan on changing port timing at all at this time. Since I am unsure of where to go with it.

I may decrease the volume in the intake manifold where it creates a transfer port on that side.

Anyone else ever mess with one of these little snow throwers before?