I'd firstly like to introduce myself, I live in Oregon and work as a machinist, I cut two to three cords of wood per year plus whatever we burn in hunting camp (which can be a LOT). I always just ran my saw and kept it fed and well maintained. I discovered this site after looking for more power out of my ms 310. I quickly discovered that it is in fact a pig in comparison to a pro saw. Turns out my brother in law had an 036 and 044 that needed homes. I sold the 310 and now have five saws that followed me home. So after some lurking and nurturing my new addiction to hand held two stroke fun I have a question the search results did not answer. I have an Echo 280e that will run but spits fuel out the carb throat the entire time. It came with no air cleaner so that will be fixed before going into service as a quad/truck saw. I ave not done a compression or pressure/vac test as I got it to fire and run. The carb settings that got me running are suspect though. Low screw turned to the seat and high one and a quarter out just to the point of not smoking clouds. My guess is that the carb needs rebuilt or replaced when combined with spitting fuel and the all the way in low needle. Saw rebuild kits for $8 on fleabay, haven't checked complete carb prices but I'm not daunted by a rebuild. Am I tracking the right problem here? And reed valves are new to me as far as tuning and performance, how do I know if they are good or not? This seems like it'd be a good limbing/brush saw if it ran well. Right now though it spools up pretty slowly, at the point I wouldn't want to clear anymore than a few branches with it. Thanks in advance, this site is great!

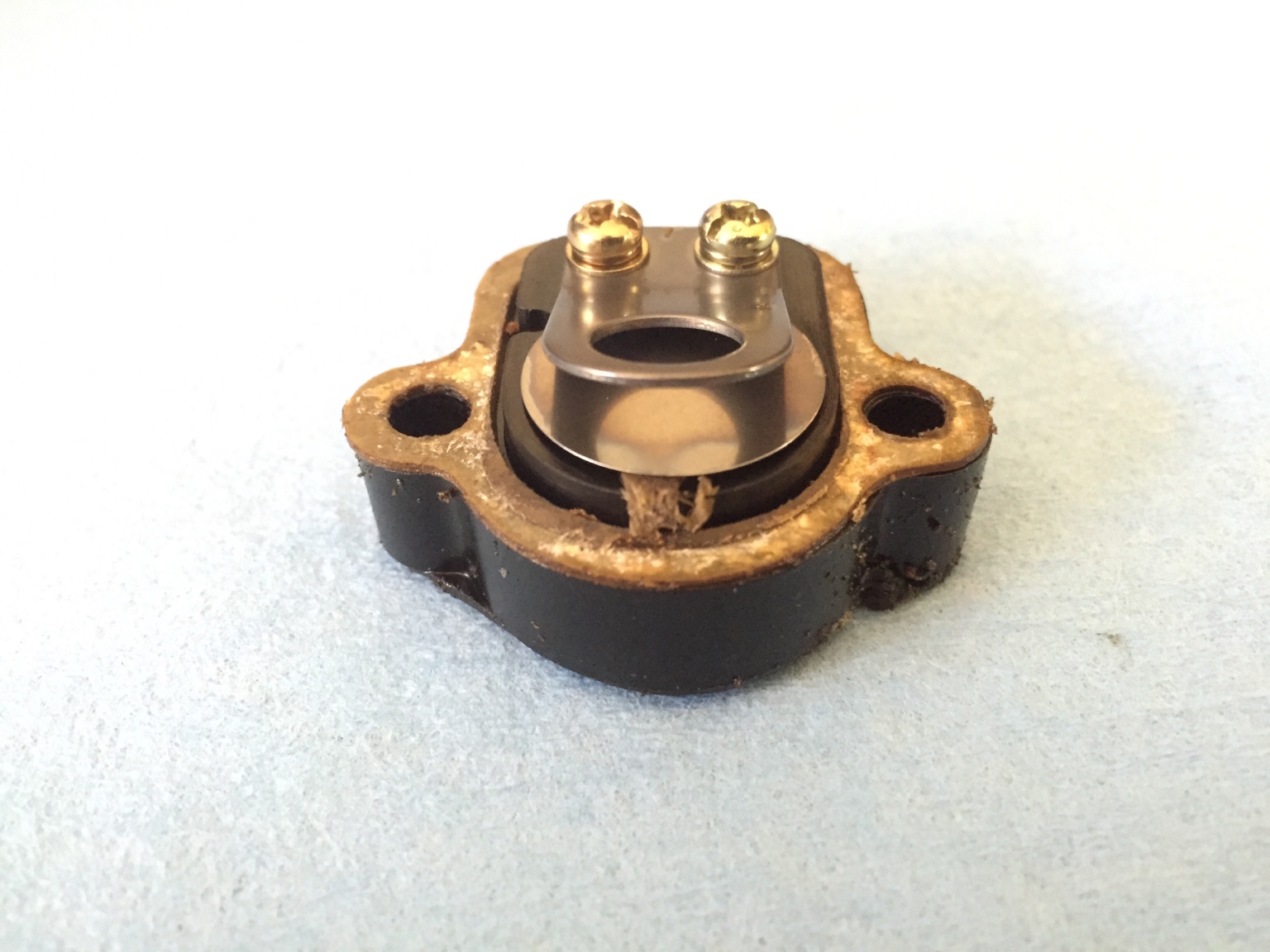

Just because it's not a thread without pics [emoji6]

Sent from my iPad using Tapatalk

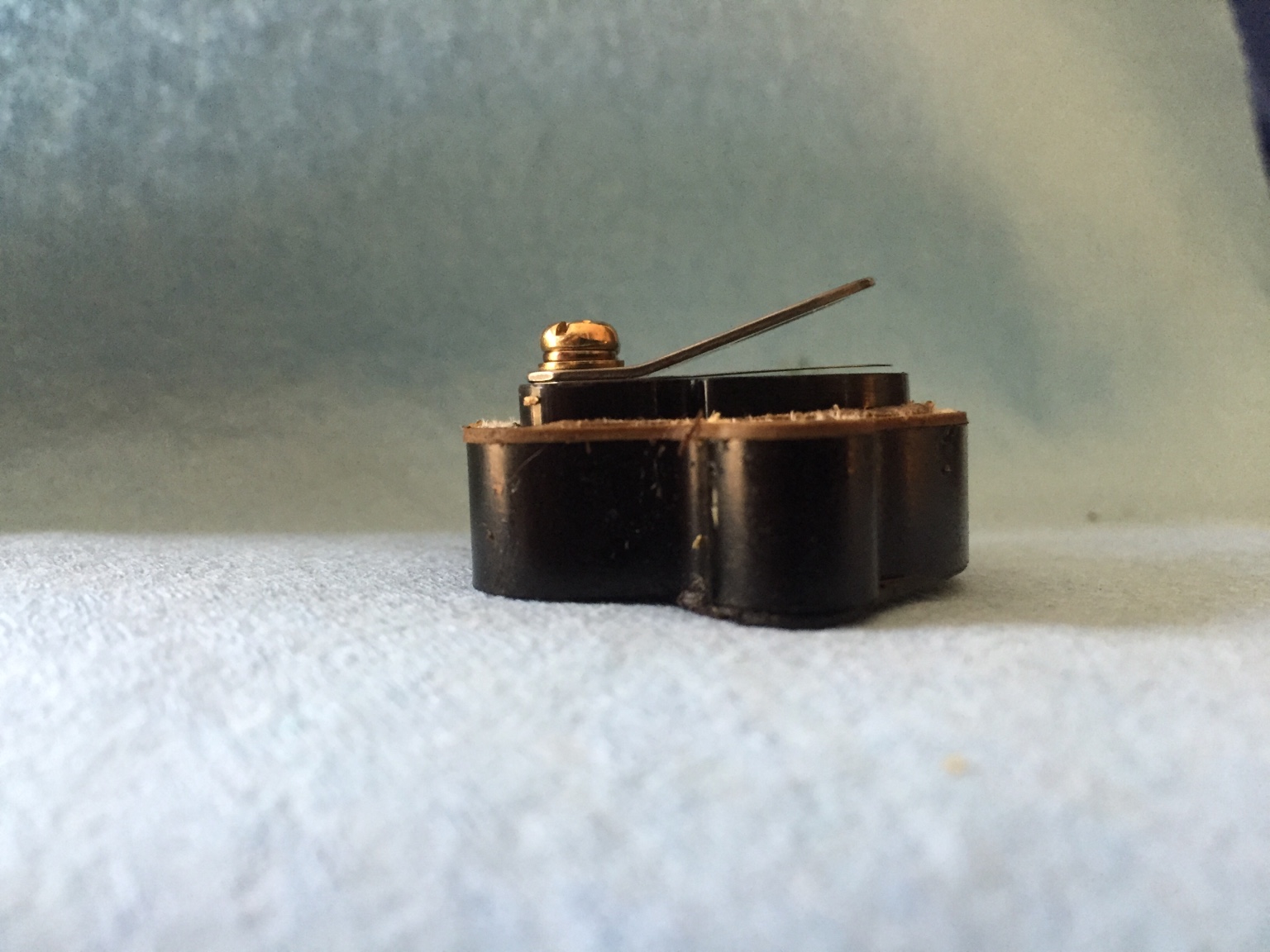

Just because it's not a thread without pics [emoji6]

Sent from my iPad using Tapatalk