you didn't answer my questions. here they are again. did you install the boiler yourself? or did it come with the house? did you have this problem last year?My husband got home and went out to check to see what was going on and temp is fine. Everything was right with the boiler. Temp settled. He checked gasket and blower and everything was good. Thinking maybe a piece of wood or ash fell down when blower was running and wedged it open. Possibly it fell loose when I opened the door. Not sure, but all seems fine now.Will keep an eye on it!

We have a continuous loop, so water flows 24/7 through the system regardless of whether furnace fan is on or off. We notice that when not calling for heat (thermostat controlled fan on furnace) the temps in and out at the stove are within 10 degrees typically usually around 7 or so. But almost instantly when the fan kicks on the gauge out at the OWB drops down. It literally happens within seconds while you are watching it.

On the air lock/air bubble note how much water should you be running through it to check? We ran 6 gallons out of it when we first noticed it felt a little sluggish. There was a little air that came out but this was right after new pump install so we expected to see a little air. And like I said we only are maybe 30ft in and then 30 feet back to OWB. Should we try running even more through it?

And 120 was return temp when stove was up at 210, with furnace fan running.

We just installed a Taco 007 pump. It's what the dealer had (I've heard bad things--maybe it's ok). We did have Grundfos UPS 15-58FC prior to this and it was set to low initially so we tried it on its highest (3) setting and it didn't change our heat output inside the house so then we thought the pump was just bad but we probably didn't even need to change it out to begin with.

This is our first winter with the OWB and it just feels like it's heating less than when we first started out.

Also did you bleed the air from the lines by cracking loose the bolts at the pump manifold when you installed it? cause if you didn't then you have air trapped in your pump. and its possible you already damaged the fins of your motor. its POSSIBLE, I didn't say it happened. but its possible. it sounds like you have air trapped in your system. do you have an air separator in your system? cause if not then you need one. it could be a number of problems. we are trying to help you narrow down the problem. but if you don't answer our questions then we can't help you. here is a heat temp gun for about 10 bucks. http://www.ebay.com/itm/Digital-Tem...614385?hash=item3f668f69b1:g:xXIAAOSwAPlXgxWa

spray paint the spot you check with FLAT BLACK PAINT before you take a temp reading. and hold the gun right on the BLACK spot. also check it on a METAL surface. DO NOT CHECK IT ON THE PEX LINES. and do not check it from a foot away. hold the gun right on the flat black metal spot. another possibility is that your heat exchanger could be plugged. please let us know if your boiler overheats again. thanks.

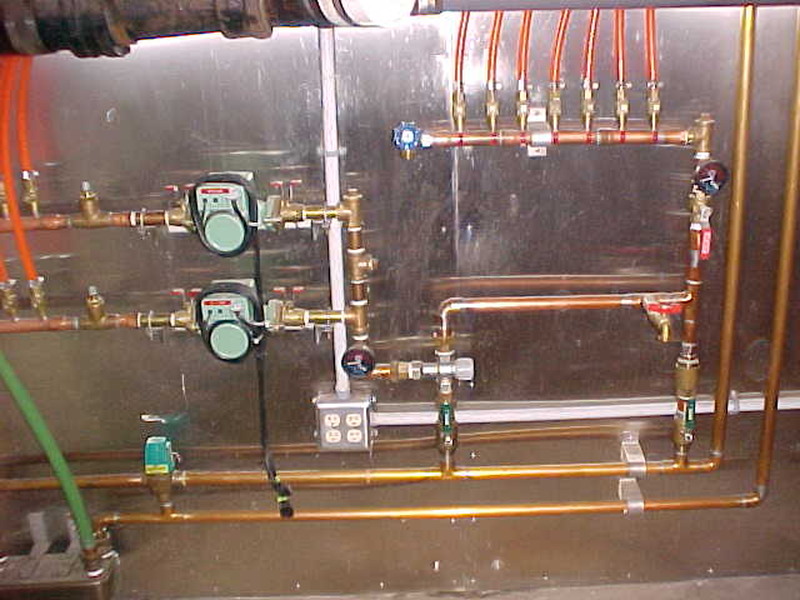

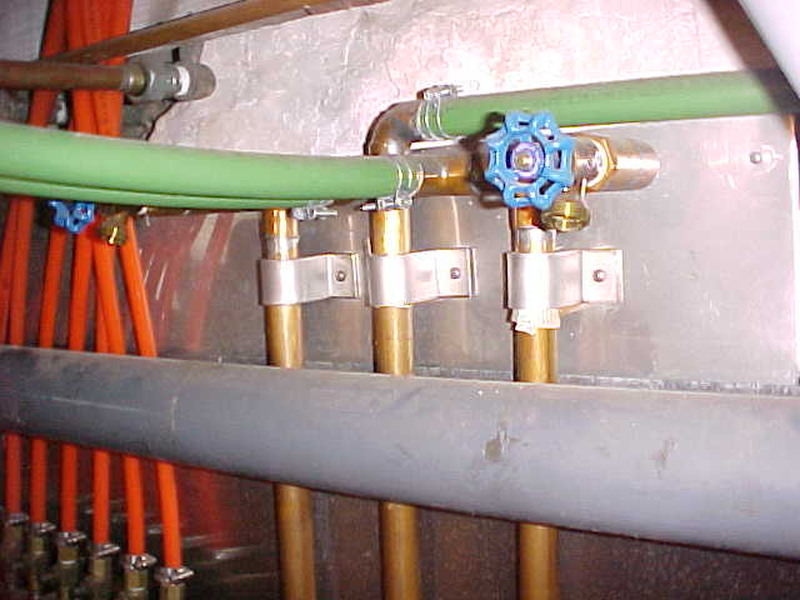

first thing you need to do is tell us when the system was installed and post a couple pics of the pump and heat exchanger. if you just recently installed the system and the pump is mounted in the house. and the pump is mounted too high it could be trapping air in the pump and not flowing the water. or the pump could be mounted wrong and be trapping air. or it could be countless things. we need more specs and info.