keaton64

ArboristSite Lurker

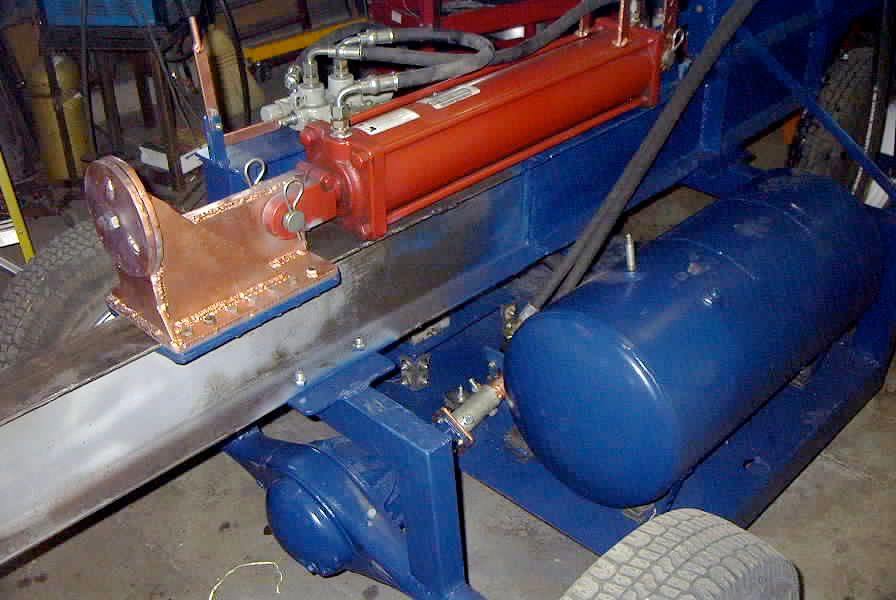

I was thinking of converting a portable air tank into an hydraulic reservoir for the log splitter I am planning to build.

Will this work, has anyone ever tried it?

Will this work, has anyone ever tried it?

ray benson said:How about a 16 gallon stainless steel beer keg. Got this one from the scrap/recycle center.

Looks dandy; not rust there. Big enough too for some reserve!

Looks dandy; not rust there. Big enough too for some reserve!ray benson said:How about a 16 gallon stainless steel beer keg. Got this one from the scrap/recycle center.

keaton64 said:my design is for a 10 gallon air tank, i think that would be ok for a 11 gmp pump.

That would be a heck of a lot bigger than what the commercial splitters do. My NorthStar (Northern) has an 11 gpm pump, and the tank is a mere 3.5 gallons. Perhaps that is why they recommend tranny fluid if the ambient temp goes over 75 deg. (F).keaton64 said:my design is for a 10 gallon air tank, i think that would be ok for a 11 gmp pump.

Looks dandy; not rust there. Big enough too for some reserve!

Keaton 64, didn't open your picture. For me, on dialup it would take about 5 minutes to load. BMP makes big files.

Ok now I opened it. What is the volume. You should be close or bigger than your pumps GPM in gallon of reservoir volume. It is nice to have pick up not be directly from the bottom and the entrance of the return should be submerged below oil level to prevent foaming and air entrainment.

I didn't realize dialup was still available.

Thought I was on slow internet!

Enter your email address to join: