If you go over to the chainsaw section of this forum and do a search on mix ratio, you will have orders of magnitude more reading material on this subject than you will ever have time to read. If I recall, there is one thread on there from several years ago that runs hundreds of posts and gets pretty technical from both ends of the spectrum, both pro and con re: departing from the standard 50:1 ratio the manufacturers will tell you. Intersting post, but how many hours of that can you digest at a time

?

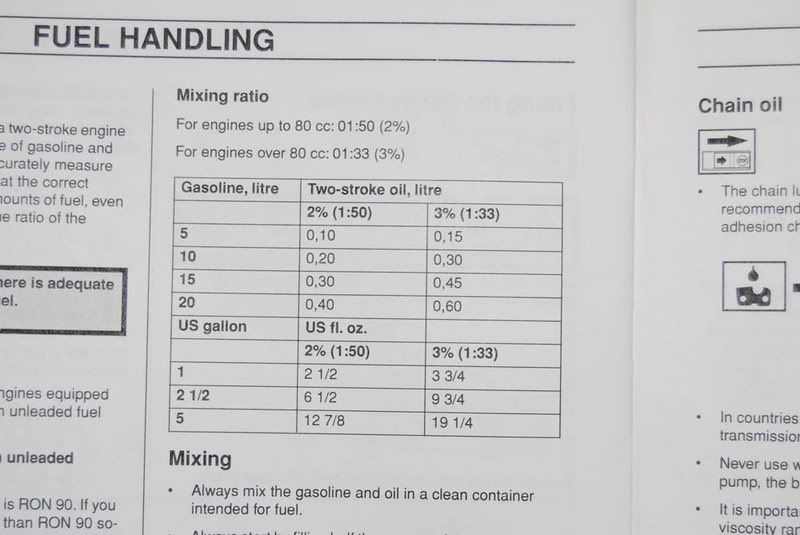

For what it's worth, and I happen to think this is quite an eye opener, when I bought my 395XP it came with the European version of the manual, and it stated that for their saws over 80cc to use 33:1 and not 50:1. (see pic below). Interesting. They don't make two different 395XP's... I bought this saw here in the US anyway... but the manual said 33:1 for their big bore saws. When I asked a Husky dealer about this he told me the saw won't pass govt emissions tests at 33:1, and that the big bore saws WILL run fine on 50:1. I find it interesting that Husqvarna is telling the Scandinavians to run 33:1 in their big saws, and the Americans to run 50:1. I run 36:1 in my 395 milling saw, and 43:1 in all my other saws. Been doing that for years, no problems.

?

?