I stripped down my Pioneer 650 today.

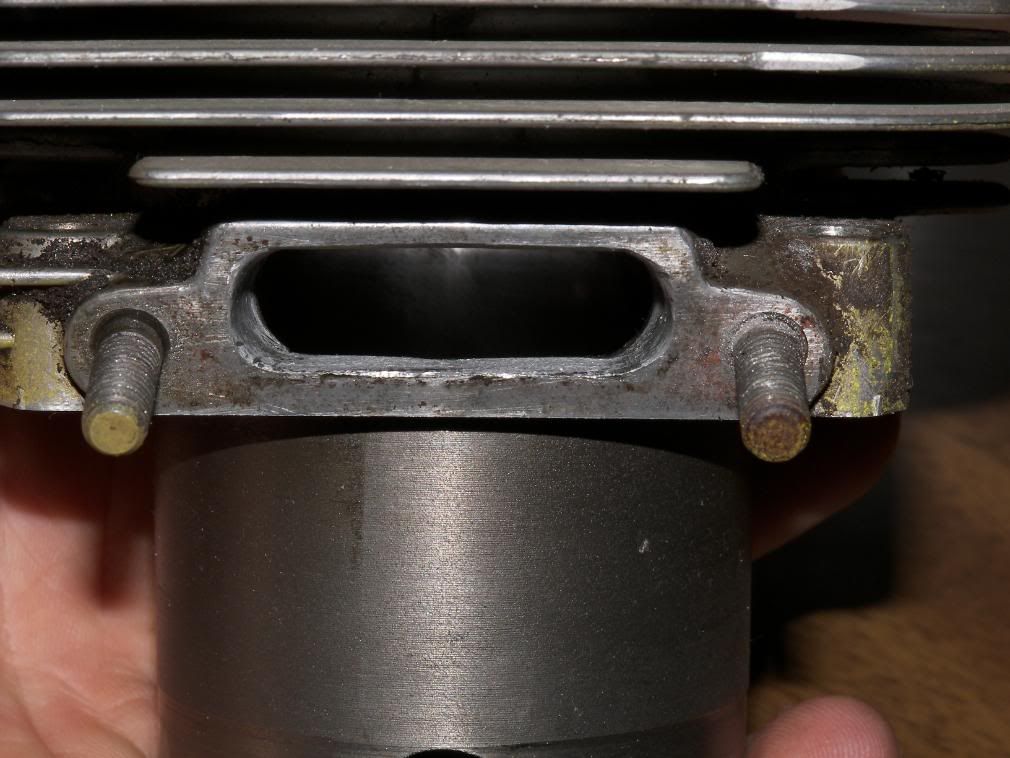

Since I chickened out on my 346xp(s'), I decided to see why the 650 was so gutless (for a 100+cc saw). It has very low compression. You don't even need a compression release. Good thing cuz there isn't one. The exhaust port is really three ports. It's nothing more then three 3/8" holes drilled side by side on the exhaust side of the jug. The muffler is AWESOME! It's cast aluminum and has these cool fins or wing things on the sides. Looks like the chrome on a 57 Chrysler 300. It's about the same size as the one on my Mini Mac though. The intake port is ok, I guess but I think I can get some real power out of this old thing.

It was pretty ballsy compared to the saws I was running at the time. My main saws were a 4600 Mac and an XL12, my brush saw was a Poulan Micro and my tree saw was an Eager Beaver.

I used to be afraid of my 650 because it has no chain brake but that doesn't bother me anymore.

Anyway, I saw a vid on Youtube of a Pioneer 600 at a county fair race. I think with some tuning, it could decimate all. The only thing is the crank. It has some weight things fastened to the counterweights. They look like they'd fly off and shell the case if revved too high. The piston doesn't look very strong either. The rod and crank are beautiful forgings though.

I'll take some pics tomorrow.

Since I chickened out on my 346xp(s'), I decided to see why the 650 was so gutless (for a 100+cc saw). It has very low compression. You don't even need a compression release. Good thing cuz there isn't one. The exhaust port is really three ports. It's nothing more then three 3/8" holes drilled side by side on the exhaust side of the jug. The muffler is AWESOME! It's cast aluminum and has these cool fins or wing things on the sides. Looks like the chrome on a 57 Chrysler 300. It's about the same size as the one on my Mini Mac though. The intake port is ok, I guess but I think I can get some real power out of this old thing.

It was pretty ballsy compared to the saws I was running at the time. My main saws were a 4600 Mac and an XL12, my brush saw was a Poulan Micro and my tree saw was an Eager Beaver.

I used to be afraid of my 650 because it has no chain brake but that doesn't bother me anymore.

Anyway, I saw a vid on Youtube of a Pioneer 600 at a county fair race. I think with some tuning, it could decimate all. The only thing is the crank. It has some weight things fastened to the counterweights. They look like they'd fly off and shell the case if revved too high. The piston doesn't look very strong either. The rod and crank are beautiful forgings though.

I'll take some pics tomorrow.