Kubota king

ArboristSite Lurker

Hello all,

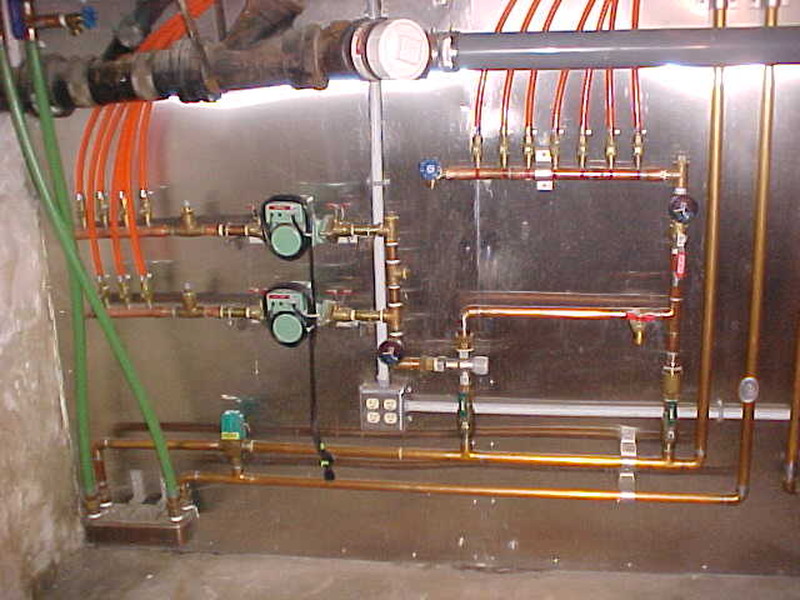

Needing some solid advice. My system is a Mahoning OWB 200 model with a taco 00R pushing 85' of 1"pex to a taco 5000 series 1" mixing valve with (3) 1" crimp elbows to reifing 6 loop manifold with 1/2" loop length 265' +- 5' and returning thru adjacent 85' 1" pex and a couple 1" sharkbite ball valves on each end and isolating pump. I ran head and gpm calcs. But something is wrong somewhere. Actual system performance is extremely low. With mixing valve opened all the way for less restriction (supply water to hot! 160) each loop is getting .4 gpm and delta t is about 60° at best! I need to speed things up but unsure of why! OWB is now very inefficient trying to recover low water returns. Any advice/ideas besides bigger pump? 00R is rated for 15 max head and 12.5 gpm at respective ends of curve. If all was as expected I should be seeing 6-8 gpm give or take rather than 2.4... floor is well insulated had has no problem maintaining 70° set point (doesn't kick on often) cold wv weather hasn't set in yet either!

Needing some solid advice. My system is a Mahoning OWB 200 model with a taco 00R pushing 85' of 1"pex to a taco 5000 series 1" mixing valve with (3) 1" crimp elbows to reifing 6 loop manifold with 1/2" loop length 265' +- 5' and returning thru adjacent 85' 1" pex and a couple 1" sharkbite ball valves on each end and isolating pump. I ran head and gpm calcs. But something is wrong somewhere. Actual system performance is extremely low. With mixing valve opened all the way for less restriction (supply water to hot! 160) each loop is getting .4 gpm and delta t is about 60° at best! I need to speed things up but unsure of why! OWB is now very inefficient trying to recover low water returns. Any advice/ideas besides bigger pump? 00R is rated for 15 max head and 12.5 gpm at respective ends of curve. If all was as expected I should be seeing 6-8 gpm give or take rather than 2.4... floor is well insulated had has no problem maintaining 70° set point (doesn't kick on often) cold wv weather hasn't set in yet either!