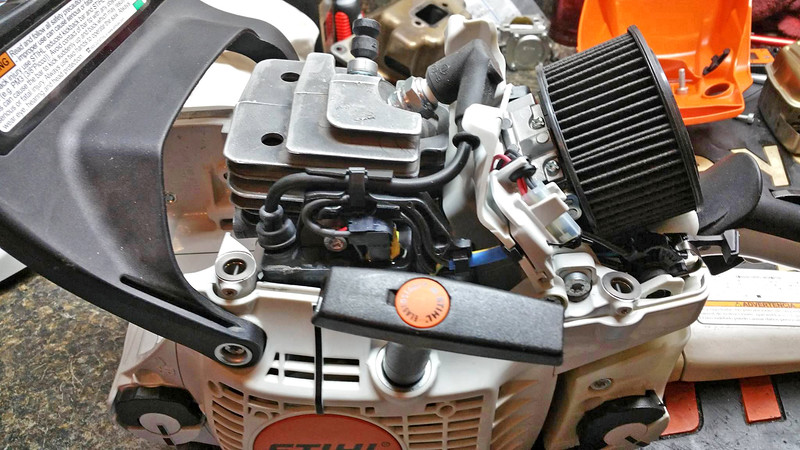

You guys like build threads? Well, I haven't done one in a while. They take time that I don't usually have to spend, but had to show off this fantastic runner. This saw has blown me away like few others. Let's get started.

Hey, what's in there?

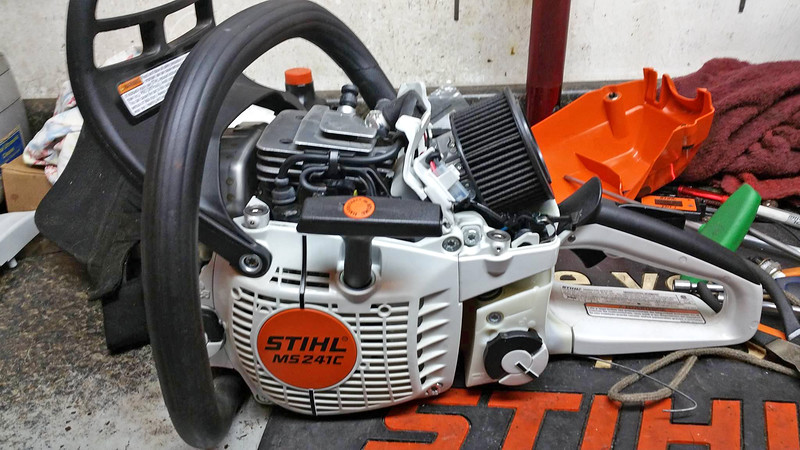

Ah, it's a new MS241C and a free t-shirt thrown in to boot. Thanks Mark!

My model for the day, lol.

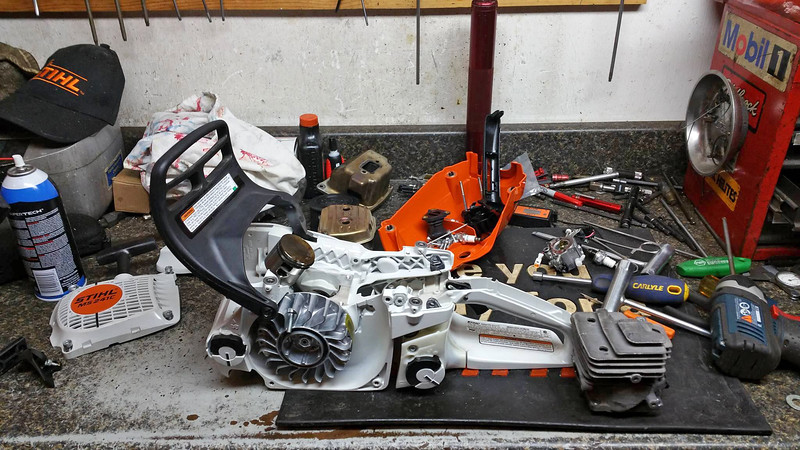

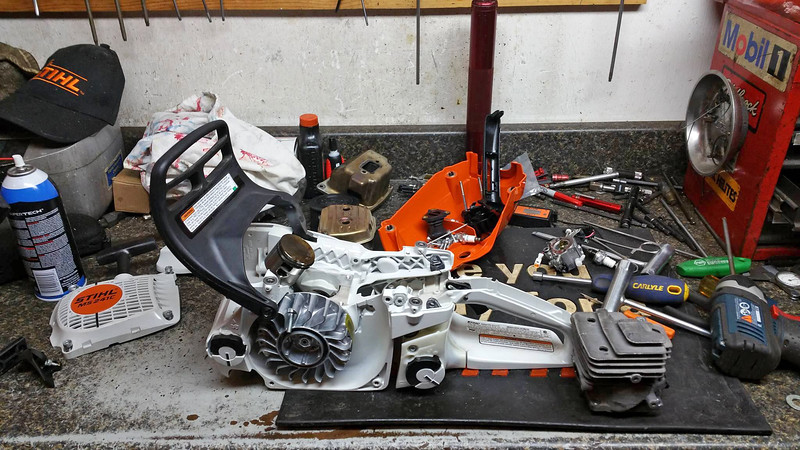

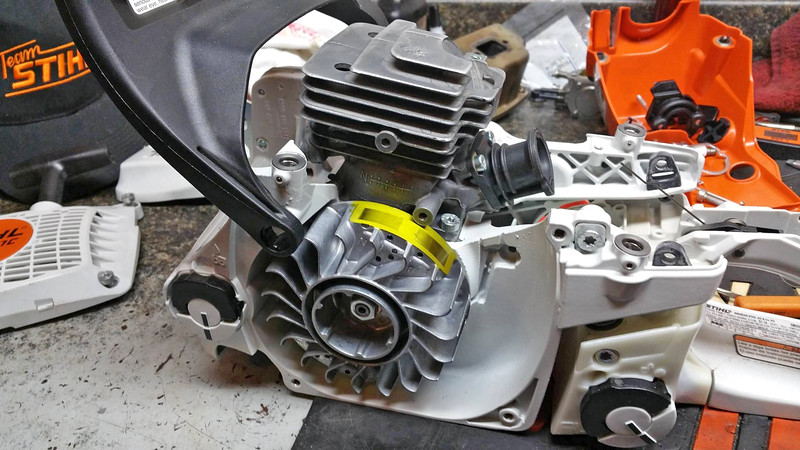

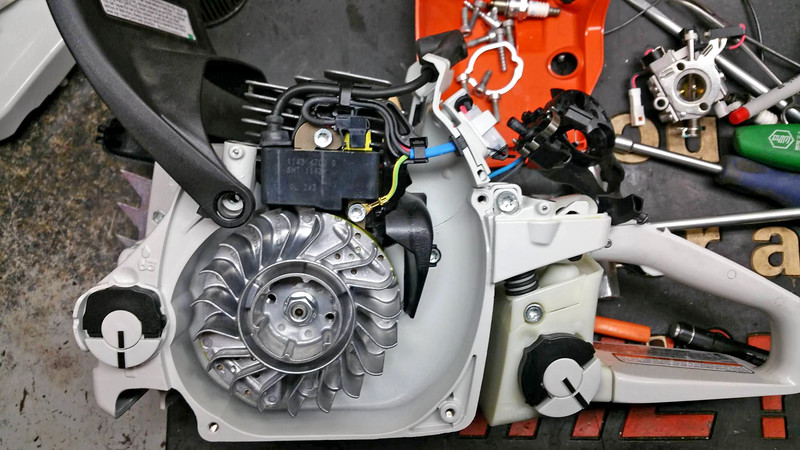

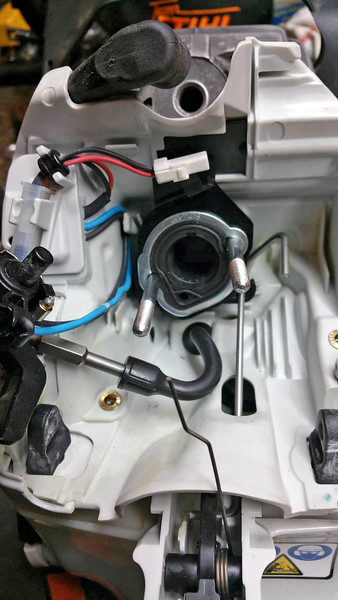

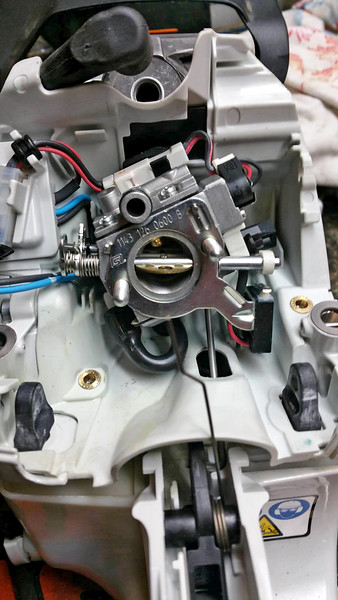

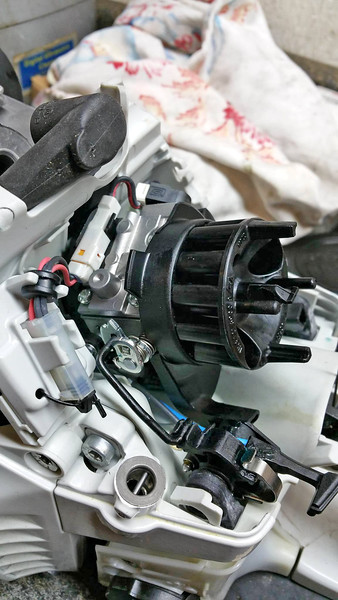

I fired it up for 10-15 seconds to make sure it ran OK, and apart it came.

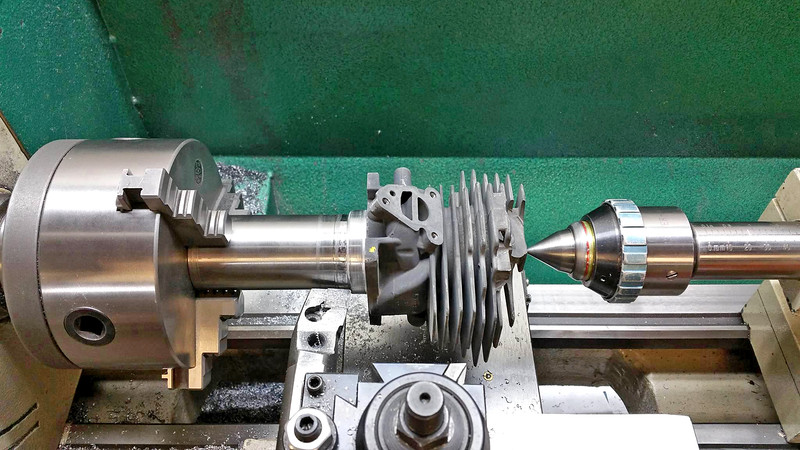

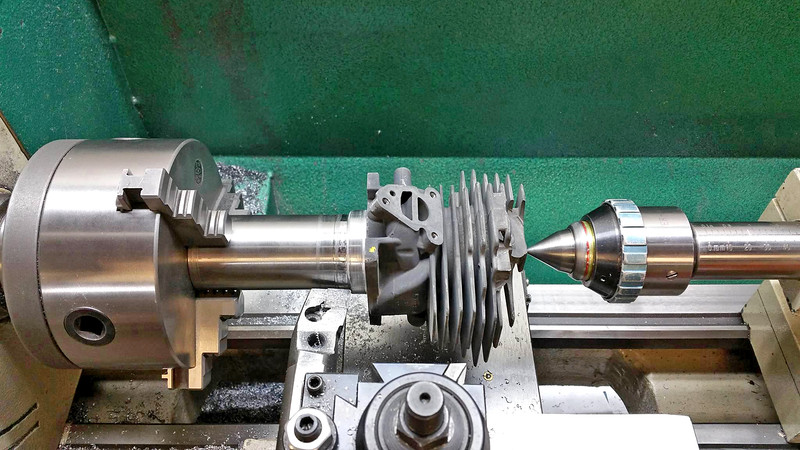

Hey Big Brother. Do you think I could run like you someday? Well, let's see what we can do about that.

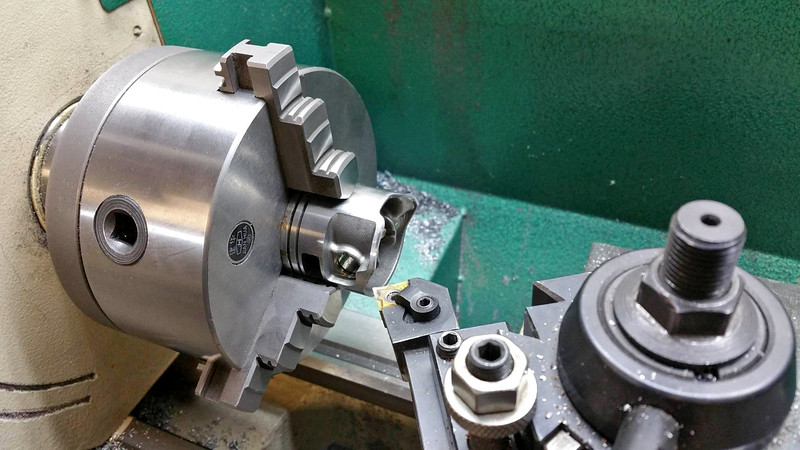

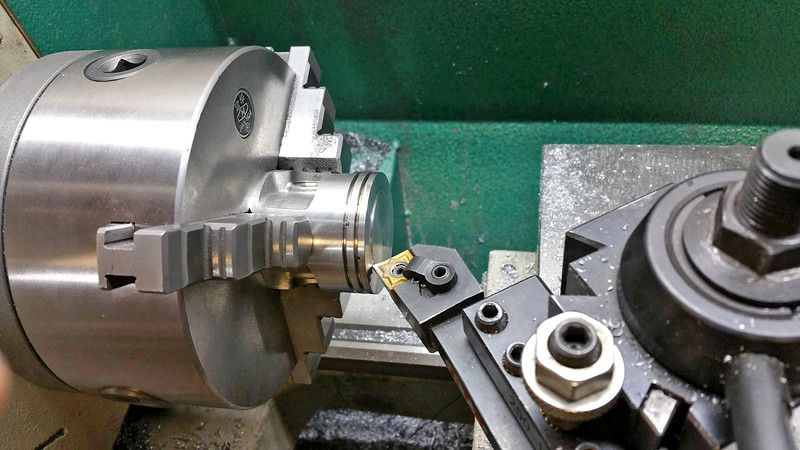

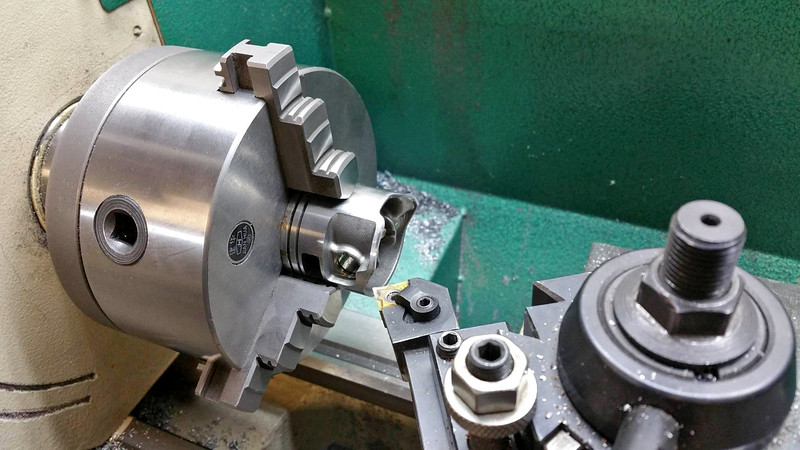

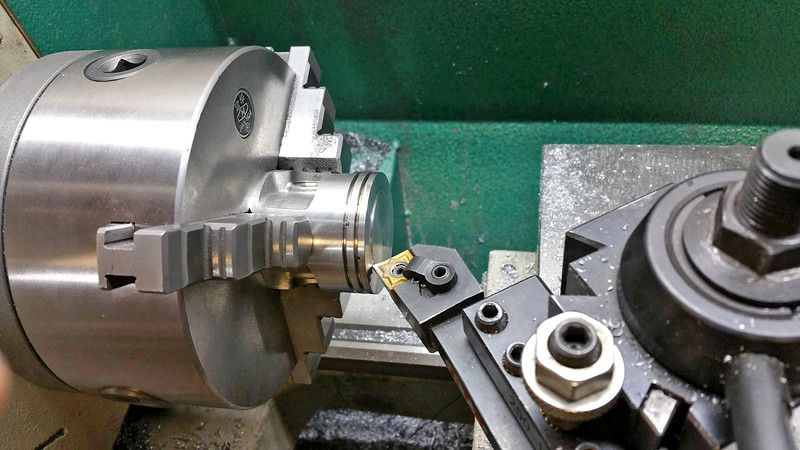

Squaring up the base of the piston so that it will set perfectly square to cut the popup.

Hey, what's in there?

Ah, it's a new MS241C and a free t-shirt thrown in to boot. Thanks Mark!

My model for the day, lol.

I fired it up for 10-15 seconds to make sure it ran OK, and apart it came.

Hey Big Brother. Do you think I could run like you someday? Well, let's see what we can do about that.

Squaring up the base of the piston so that it will set perfectly square to cut the popup.

I really enjoy the type of vids you do. The restarts, the piss revs, the screaming cuts then my favorite the lugging power for the ham fisted users like me. You should be proud

I really enjoy the type of vids you do. The restarts, the piss revs, the screaming cuts then my favorite the lugging power for the ham fisted users like me. You should be proud

with that said it obviously works well as shown in the testing.

with that said it obviously works well as shown in the testing.