OK, this is an older splitter I bought from my dad.

"Speeco" brand name, 20 ton, with 5 HP Tecumseh engine.

It's around 15-20 years old I believe. Had worked plenty of hours while he used it for primary heat wood in north central Missouri. I've used it several times in the past few months, until...

I was helping out a work buddy with his firewood. The splitter had been going strong for about three hours pretty steady, the all of a sudden it acted like it just had no power. The engine would bog down a bit, and the hydraulic piston just seemed to have no "oomph" anymore. The fluid was not low, and not especially hot. We were about done anyway, so I just packed up and took it home.

A few weeks later I tried to use it on some semi-dry oak, and it was the same as the end of the last session. Just seemed to be unable to push through anything. Engine is working fine.

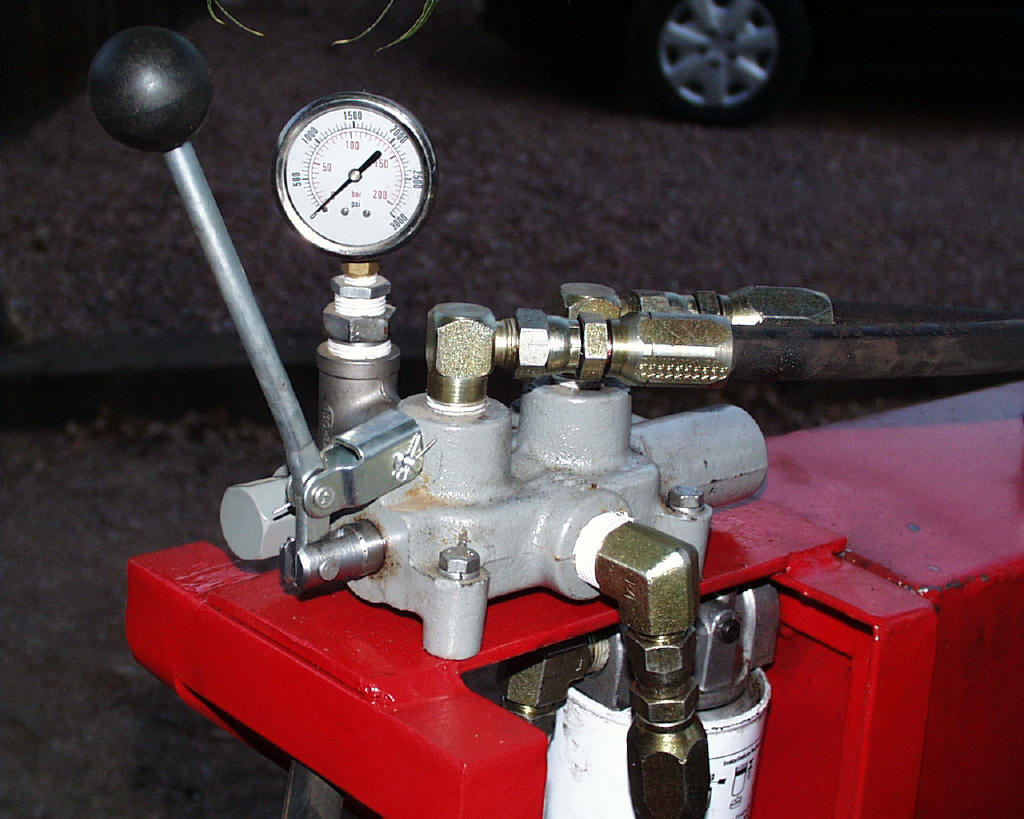

Am I looking at a "dead" hydraulic pump? (11 gpm, HC390705B)

I don't know if the filter has ever been changed. I do have a new one I just haven't gotten around to installing.

"Speeco" brand name, 20 ton, with 5 HP Tecumseh engine.

It's around 15-20 years old I believe. Had worked plenty of hours while he used it for primary heat wood in north central Missouri. I've used it several times in the past few months, until...

I was helping out a work buddy with his firewood. The splitter had been going strong for about three hours pretty steady, the all of a sudden it acted like it just had no power. The engine would bog down a bit, and the hydraulic piston just seemed to have no "oomph" anymore. The fluid was not low, and not especially hot. We were about done anyway, so I just packed up and took it home.

A few weeks later I tried to use it on some semi-dry oak, and it was the same as the end of the last session. Just seemed to be unable to push through anything. Engine is working fine.

Am I looking at a "dead" hydraulic pump? (11 gpm, HC390705B)

I don't know if the filter has ever been changed. I do have a new one I just haven't gotten around to installing.