You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

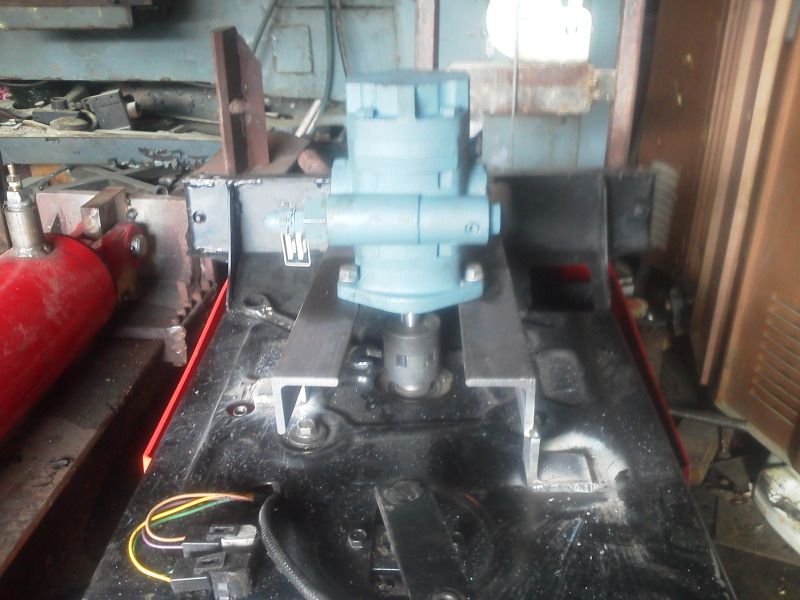

Starting a processor build.. pictures..FINALLY FINISHED!!

- Thread starter blkcloud

- Start date

Help Support Arborist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Your thread has already answered one of my questions. I have the same cylinder from Northern. My plans are to relocated the ports 90*. You used sch 80 3/4pipe ports. My plans are for 1in sae. Do you think there is enough metal in the cylinder tube to support 1in ports? I will probably just plug the exsisting ports. I have also considered just cutting off the base pin boss and rotating 90*, but I still have to address the ports.

My plans are for 1in sae. Do you think there is enough metal in the cylinder tube to support 1in ports?

Are you planning on drilling and tapping the cylinder or welding on a threaded coupling? if drilling and tapping.. then no.. not enough wall thickness.. welding a coupling... yes..

Are you planning on drilling and tapping the cylinder or welding on a threaded coupling? if drilling and tapping.. then no.. not enough wall thickness.. welding a coupling... yes..

I Most likely will be welding a coupling. My concern is that by going with a much larger fitting, that I might be getting into the seal area of the piston with the hole.

This is no longer a lawn mower.. from no own its refered to as a "power unit"..LOL..

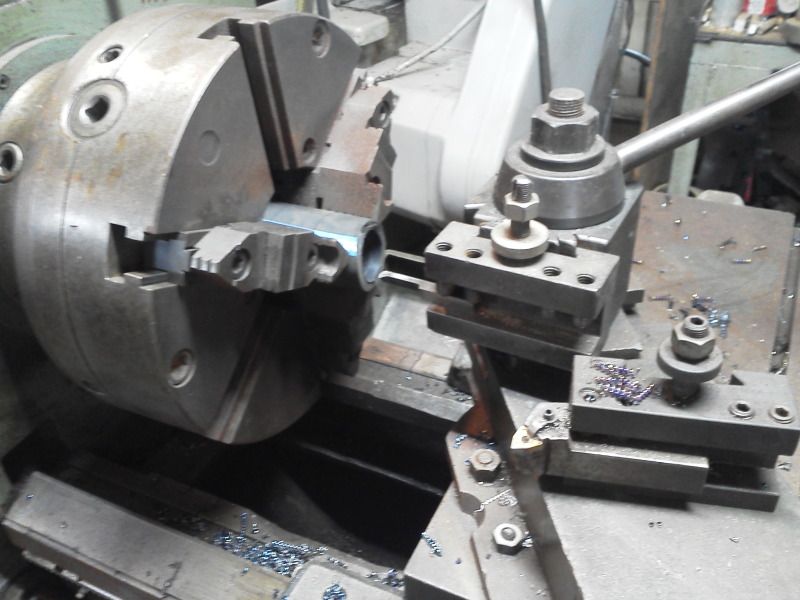

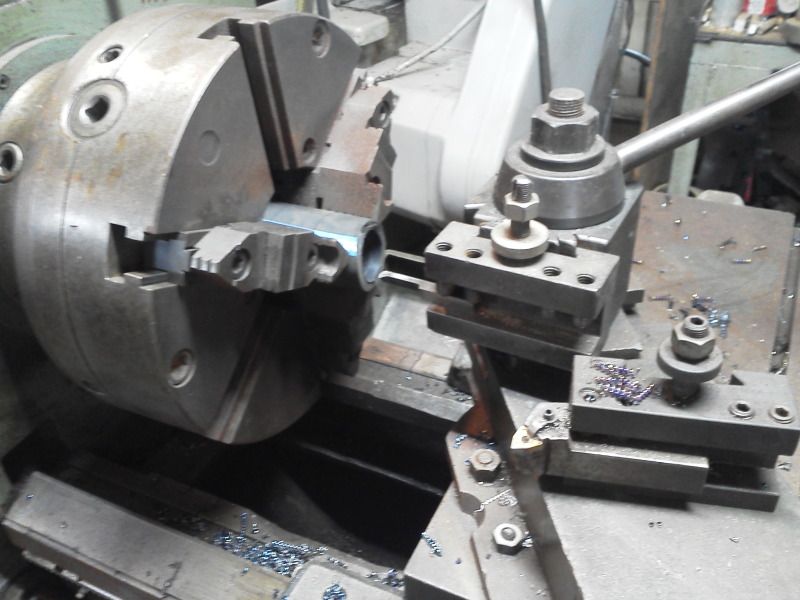

also cut the axle and turned a solid shaft to fit inside the tubing to extend the axle 18 inches... enough to make it wide enough for my power unit to sit between the wheel and wheel my log conveyor will be ,atop of the cylinder.a little irony here.. back in the 80's when I originally built my splitter I shortened the axle ,probably about the width i'm now extending it...haha.

also cut the axle and turned a solid shaft to fit inside the tubing to extend the axle 18 inches... enough to make it wide enough for my power unit to sit between the wheel and wheel my log conveyor will be ,atop of the cylinder.a little irony here.. back in the 80's when I originally built my splitter I shortened the axle ,probably about the width i'm now extending it...haha.

I re plumbed my hyd. tank from 3/4 to a 1 1/4 pipe ..that is what the intake on the pump is.. I also got 1 1/4 suction hose, its rubber with one strand of wire in it.. its tough.. I tried and tried to get it to go over the threads on my pipe coming out of the tank but just could not get it to go.. well I did something that i have always heard to be impossible.. I threaded the inside of the rubber hose.. well kinda threaded it... I put it in the lathe and made a couple of passes with a threading tool with the lathe set on 11 1/2 tpi.. it sorta kinda cut the hose, but it was enough that it screwed up on the pipe with out much problem.. all I need now is a hose clamp..

MechanicMatt

Cut Split Stack Burn

blkcloud, keep the pic's coming, I have access to a miller mig 110, lincoln 220, Lincoln stick 220, miller plasma cutter, and several bridgeports, dying to see your build completed. Im definitely gonna have a four way on the end mine, make it so it slips over the single blade, make it quick change.

Got the valves for the ram and the log lift mounted.. only to find out later in the day that the valves I'm using are not "power beyond".. live and learn.. I have never heard this term before but for anyone who is going to do something like this.. when you plan on having more than one valve or something else running down stream in your hyd. system your first valve or second or third..how ever many you have it has to be power beyond.. your last valve does not..

iowa

Addicted to ArboristSite

Yes. I learned that also. It maybe cheaper to just buy a 2 spool valve. One with a detent and the other spring to center for your lift. Look on www.splitez.com for a valve or valves.

ChoppyChoppy

Tree Freak

This is a processor or just a splitter?

Finally got my log lift built, will try it out this weekend hopefully.. so far so good,, its 3 feet long with a 3 foot "foot"..lol I cut the wedge off and will move it back about a foot, my new cylinder has more stroke than my original one did... I see people weld their wedges on with 20-25 multiple pass beads.,., this one , I welded on in high school about 1983 with a single pass 7018.. I cut the weld with a torch and then had to beat it off with a sledge hammer..

Sawdust inspector

ArboristSite Operative

- Joined

- Oct 18, 2014

- Messages

- 192

- Reaction score

- 370

Nice ur getn there it took me awhile to build mine wife n kids take up a lot of time

Sawdust inspector

ArboristSite Operative

- Joined

- Oct 18, 2014

- Messages

- 192

- Reaction score

- 370

Try to put a place or table for the splits to land so ur not bending to the ground Ive had lots of compliments from my helpers that they like not picking em off the ground when they can't keep up

Sawdust inspector

ArboristSite Operative

- Joined

- Oct 18, 2014

- Messages

- 192

- Reaction score

- 370

I also can remove the foot of my log lift so I can roll blocks off my flat racks right onto the splitter

Sawdust inspector

ArboristSite Operative

- Joined

- Oct 18, 2014

- Messages

- 192

- Reaction score

- 370

I'm gonna convert a bale elevator into my wood elevator with a hydro motor I can run off my splitter or tractor when I use my buzz saw

archertwo

ArboristSite Member

I'm going to build a chute on the end that goes into my pickup bed.. each time one splits it will push one into the truck..

If you do this make sure you have the splitter hooked up to the truck (hitch is the best place) in some way so the wood doesn't just push the splitter back instead of the splitter pushing the wood into the truck box. It will get to be a heavy push quite fast.

Similar threads

- Replies

- 17

- Views

- 2K

- Replies

- 76

- Views

- 6K