All -

I have several Contra's; figured it's time to go through one. And since I'm documenting it anyway for my own records, figured y'all may as well come along, too.

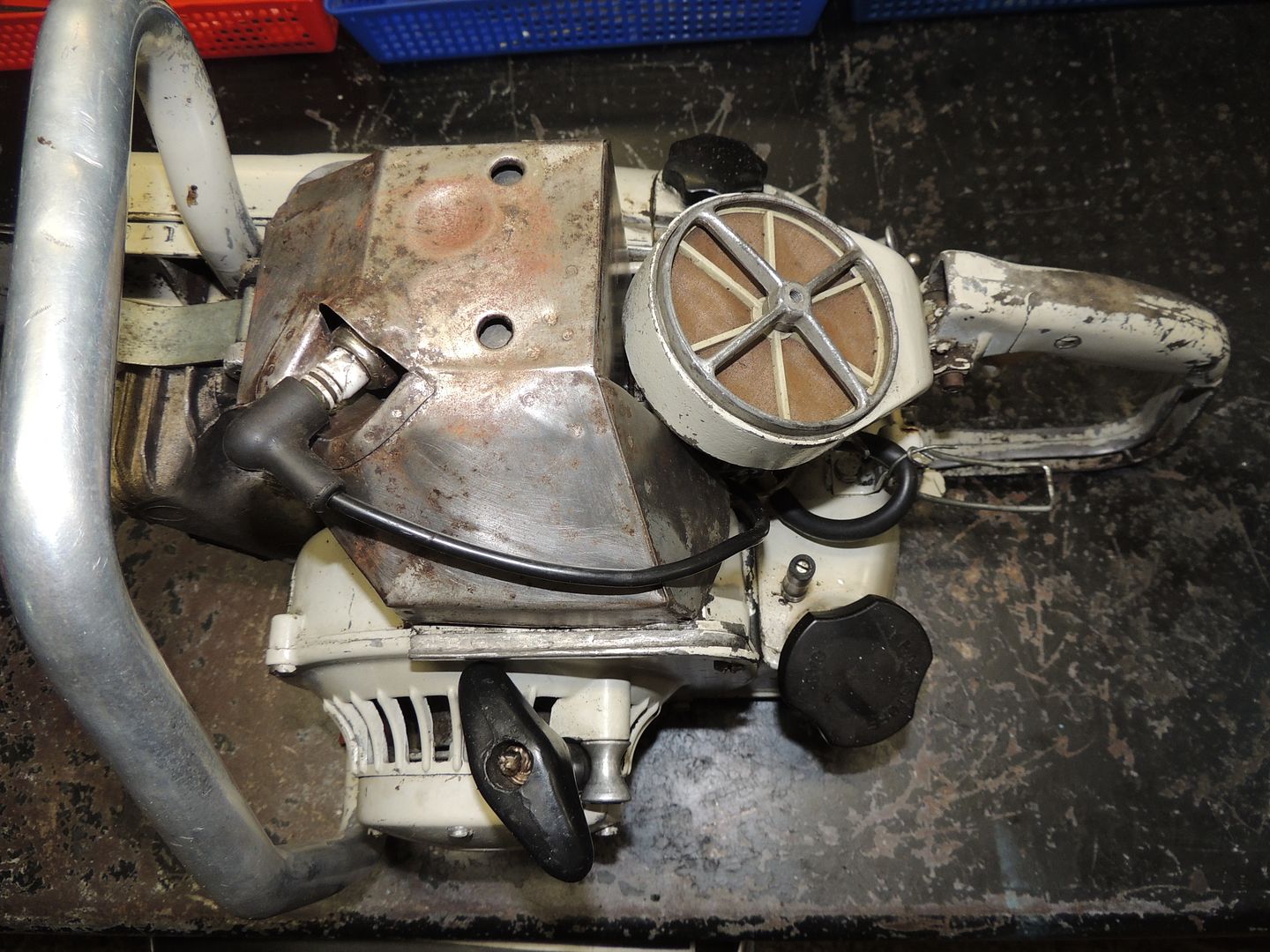

And here she is, sitting on my workbench -

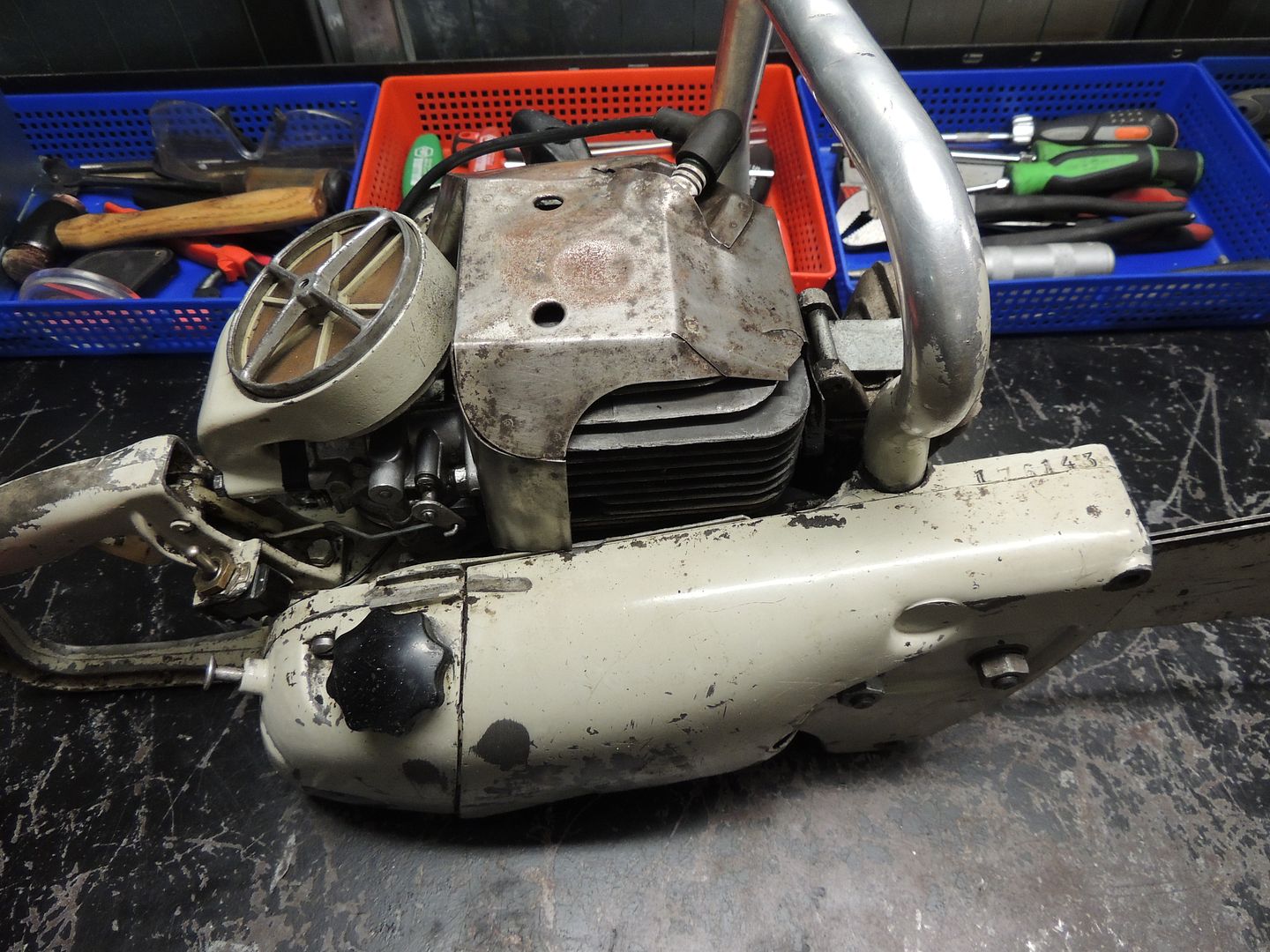

I bought the saw through a popular auction site in early January 2017. Given the condition, it appeared to be a low-hour saw, so I pulled the trigger. It came with the 21" Stihl Duromatic hard nose bar, but it was missing the dogs and chain. Original bars are out there, but not real easy to find. You can still find NOS dogs, however.

The serial number is 176143; this doesn't tell you the date, but there are a few ways to figure it out. If it had the original bar (it doesn't), these are usually date coded. I have also seen date codes on mufflers, too, but I'm not seeing one on this muffler. However, you can still get an idea of when it was produced just by going from the serial number. We know that the sand cast crankcase model production ceased on 24 June 1959 with serial number 84832. And the manual oiler (which this saw has) started with serial number 112000 which appeared sometime in 1960. And then I've seen a couple of posts from folks with saws that apparently have their original date coded bars (188587 with a February 1962 bar and 208362 has a bar dated November 1962). We also know from Stihl literature that serial number 275000 was produced in December 1963. So with a bit of redneck math, my best guess is late 1961.

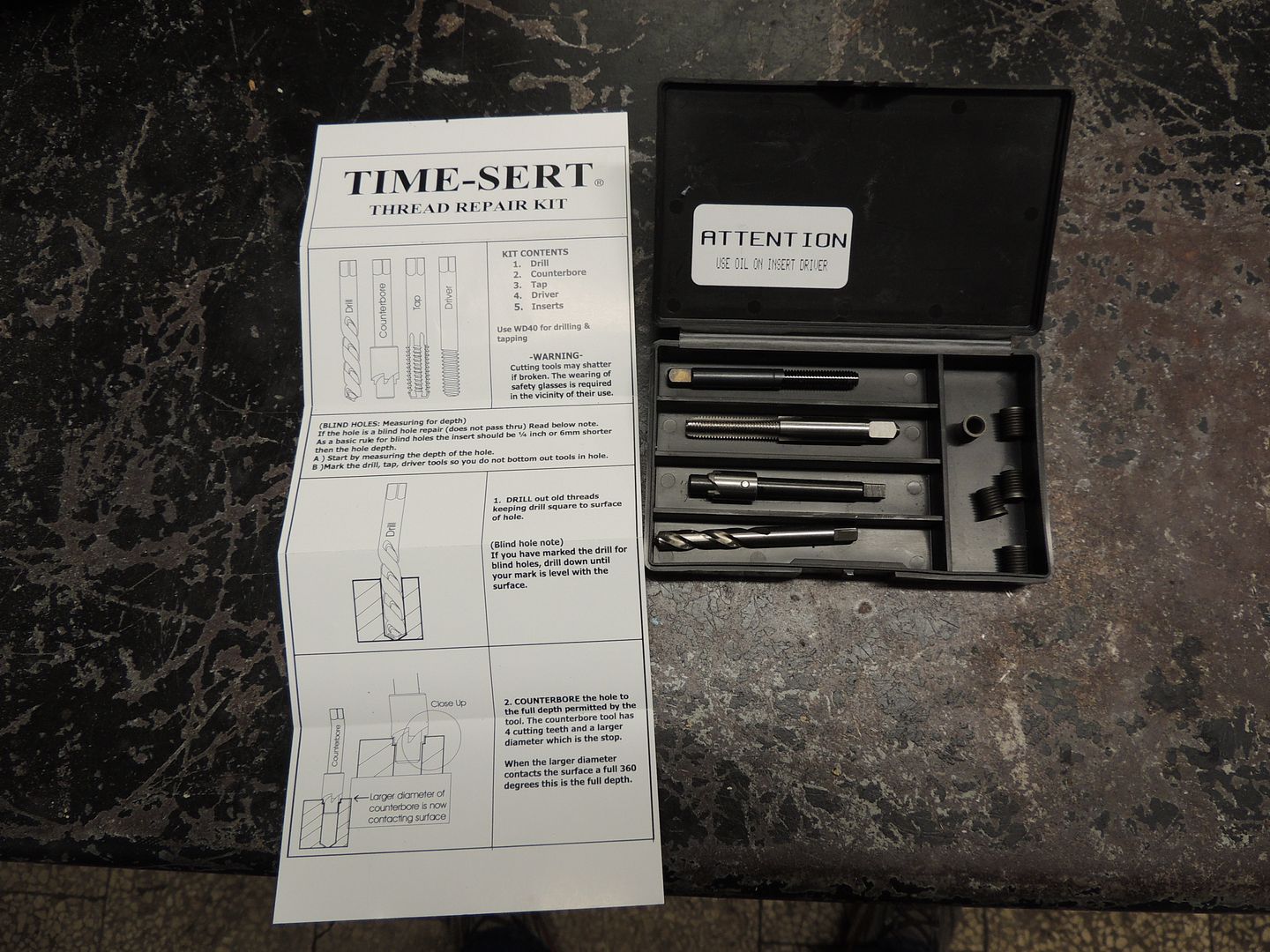

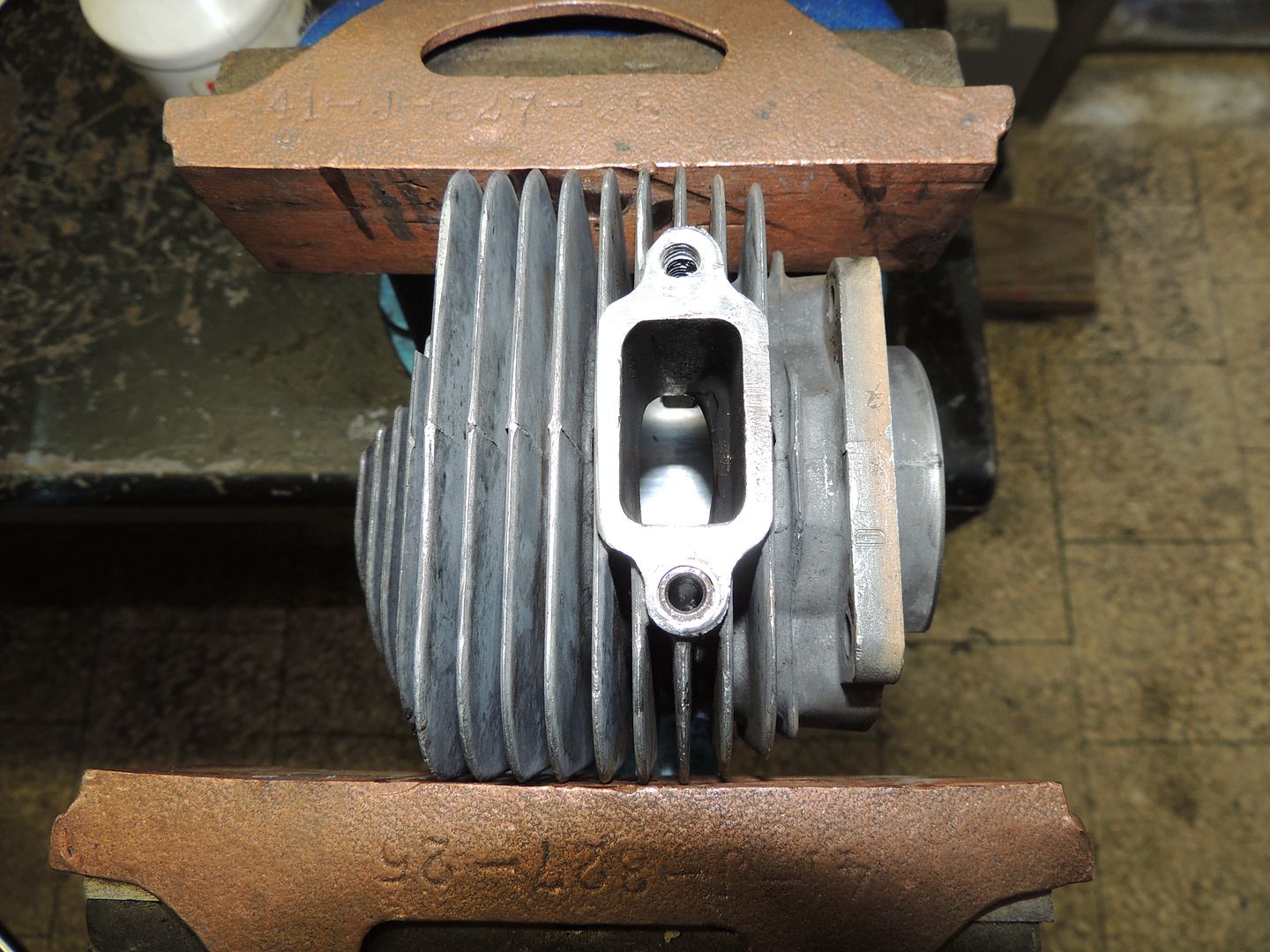

Anyway, when the saw arrived, I did a quick once-over. Compression was good - right at 140. And when I pulled the muffler to take a look at the cylinder, I realized it had a broken muffler stud -- it's about 1/4" deep; too deep to weld a nut to it and just unscrew it. I fired it up and it ran fine, but I only ran it for a minute because of the exhaust leak.

So, it's time for a rebuild/refresh. The original paint is in pretty good shape, so I don't see a need to do a media blast the current paint and re-paint it. A good cleaning and replacement of gaskets and wear items should do the trick.

Scott

I have several Contra's; figured it's time to go through one. And since I'm documenting it anyway for my own records, figured y'all may as well come along, too.

And here she is, sitting on my workbench -

I bought the saw through a popular auction site in early January 2017. Given the condition, it appeared to be a low-hour saw, so I pulled the trigger. It came with the 21" Stihl Duromatic hard nose bar, but it was missing the dogs and chain. Original bars are out there, but not real easy to find. You can still find NOS dogs, however.

The serial number is 176143; this doesn't tell you the date, but there are a few ways to figure it out. If it had the original bar (it doesn't), these are usually date coded. I have also seen date codes on mufflers, too, but I'm not seeing one on this muffler. However, you can still get an idea of when it was produced just by going from the serial number. We know that the sand cast crankcase model production ceased on 24 June 1959 with serial number 84832. And the manual oiler (which this saw has) started with serial number 112000 which appeared sometime in 1960. And then I've seen a couple of posts from folks with saws that apparently have their original date coded bars (188587 with a February 1962 bar and 208362 has a bar dated November 1962). We also know from Stihl literature that serial number 275000 was produced in December 1963. So with a bit of redneck math, my best guess is late 1961.

Anyway, when the saw arrived, I did a quick once-over. Compression was good - right at 140. And when I pulled the muffler to take a look at the cylinder, I realized it had a broken muffler stud -- it's about 1/4" deep; too deep to weld a nut to it and just unscrew it. I fired it up and it ran fine, but I only ran it for a minute because of the exhaust leak.

So, it's time for a rebuild/refresh. The original paint is in pretty good shape, so I don't see a need to do a media blast the current paint and re-paint it. A good cleaning and replacement of gaskets and wear items should do the trick.

Scott