Boon

Addicted to ArboristSite

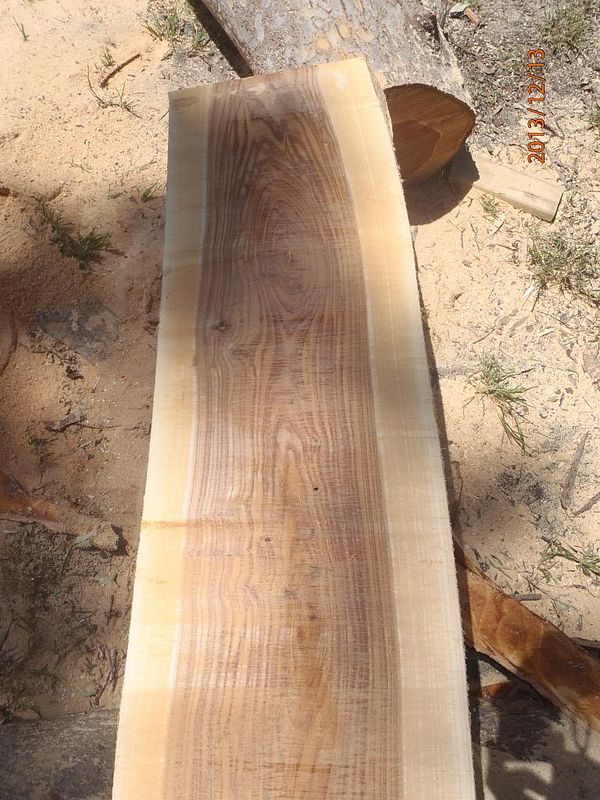

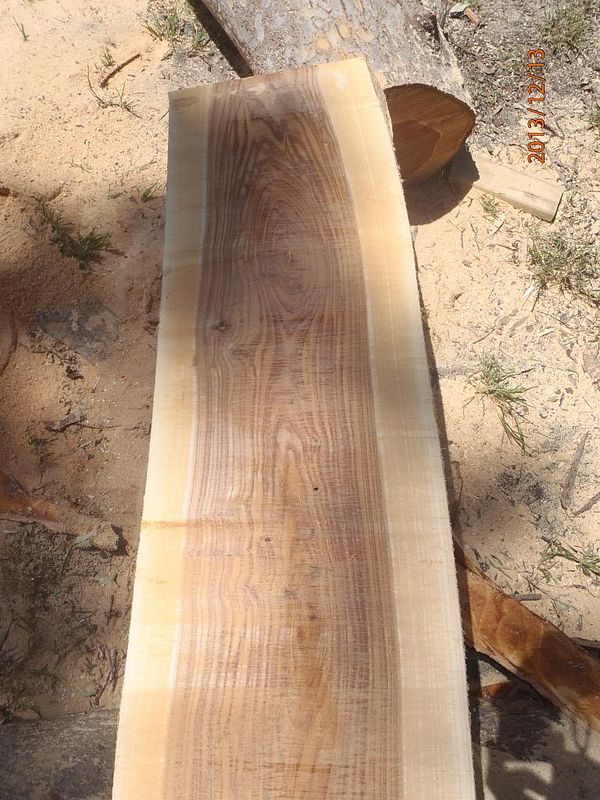

Milled out some Chinese Elm to 35 mm thickness but the timber is quiet wet and am expecting it to warp because of this and the thickness. Am thinking of strapping the boards together to try and help hold it in place along the stickers.

All the steel strapping tools look like they will not work for smaller logs as they seem too long on the tool, there is one that does nylon but I feel it may not hold enough pressure on the timber to assist in holding.

Anyone got advice or ideas on limiting timber warping or strapping and how Chinese Elm behaves during drying??

All the steel strapping tools look like they will not work for smaller logs as they seem too long on the tool, there is one that does nylon but I feel it may not hold enough pressure on the timber to assist in holding.

Anyone got advice or ideas on limiting timber warping or strapping and how Chinese Elm behaves during drying??