I'm looking for suggestions on how to build a 4 way wedge for my Lickity Log Splitter. The splitter is quite old and is nothing like you see nowadays. The wedge is static and is 14" long and 9" high. Due to the size of the wedge I can't find anything that "slips" on that is compatible.

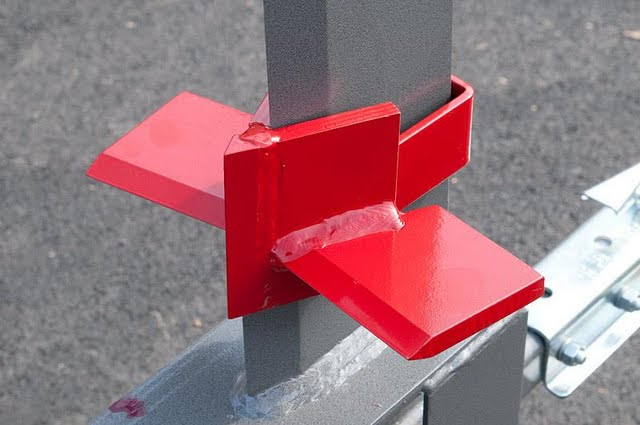

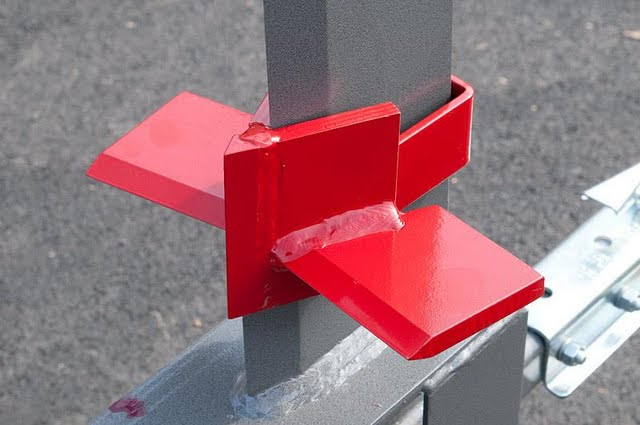

I'm thinking of building my own and having a friend weld it together. I found a guy on ebay that sells some 6" 3/4" thick wings for the sides. But I'm not sure how to make the slip on main wedge. I see some skinny single pieces of steel that is tapered on both sides, but I don't think that will work. I was thinking of getting two pieces of 1/2" 9"x14" steel and having them weld them at the same angle as my existing wedge. But I don't know how to get a good point if I just butted two pieces of steel together. Also concerned about weight. Timberwolf seems to have a nice 4 way wedge design but it almost looks like they took the two steel panels as I described before but added an additional 1" blade in front.

I obviously don't know much about welding so hoping for some suggestions that I could take to my welder friend. Thanks!

I'm thinking of building my own and having a friend weld it together. I found a guy on ebay that sells some 6" 3/4" thick wings for the sides. But I'm not sure how to make the slip on main wedge. I see some skinny single pieces of steel that is tapered on both sides, but I don't think that will work. I was thinking of getting two pieces of 1/2" 9"x14" steel and having them weld them at the same angle as my existing wedge. But I don't know how to get a good point if I just butted two pieces of steel together. Also concerned about weight. Timberwolf seems to have a nice 4 way wedge design but it almost looks like they took the two steel panels as I described before but added an additional 1" blade in front.

I obviously don't know much about welding so hoping for some suggestions that I could take to my welder friend. Thanks!