Mastermind

Work Saw Specialist

That's likely a liability thing Bob.....lawyers and **** ya know.

Is that all Latin or sumpin? Dat der made no sense to me at all.

Which seems to not be too problematicThe 461 is the same design Chris.

Why would it matter if the b and c were off? If all the saw is doing is idling what difference would it make?

The saw doesn't have a crank sensor.

If you think a saw off idle will respond the same with a bar and chain drag coefficient as it will with none or you think a mounted load on the crankshaft needs the same idle settings as an unloaded crankshaft at idle, have it your way.

Brushape ?? Is that youhttp://www.pirate4x4.com/forum/attachments/general-****-chat/918746d1370961072-another-scandal-hillary-sex-drugs-prostitutes-minors-secret-service-cover-up-memos-what-difference-does-make.jpg

If you turn your chain by hand then unmount the bar and turn the crank by hand using only the rim sprocket you should be able to understand the difference in load.

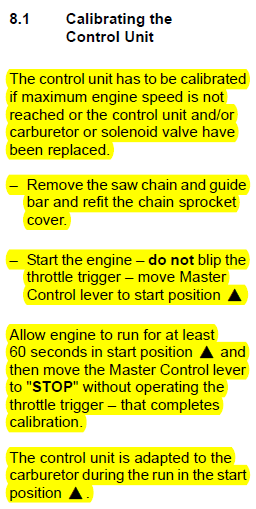

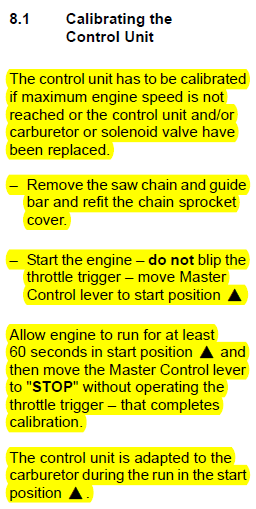

This is directly out of the MS661 Workshop Manual.

Run saws much?

Enter your email address to join: