*ryan

ArboristSite Member

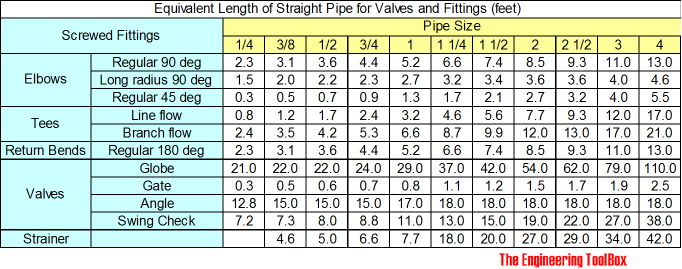

Is it better to have longer hoses with no angle connectors?

or

to have shorter hose with angle connectors?

this is mainly for the working ports

i read the feed should have as few angles as possible in it, of course mine as i got it has 4 90s on it

or

to have shorter hose with angle connectors?

this is mainly for the working ports

i read the feed should have as few angles as possible in it, of course mine as i got it has 4 90s on it