NSMaple1

Addicted to ArboristSite

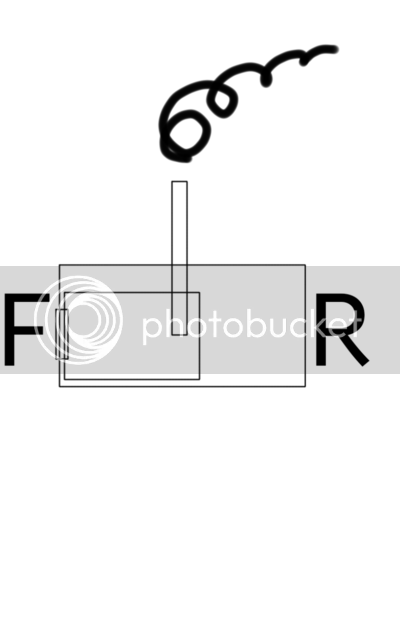

Ordered 1TDP7 Dayton blower. 146cfm stated. Figured I'd go big and can always add a fan control later if I needed to slow it down. Getting ready to order fiberglass rope for the door gasket. Looking at the 1" diameter. That looks pretty standard for boilers. Lastly I want some opinions on location for draw and return ports on the tank. I was planning on drawing from the top rear of the water jacket and returning towards the front almost directly under the firebox. The water jacket is almost twice as long as the fire box, will drawing so far away from the firebox hurt me? I've always heard that water layers and the hottest will be in the top 25%. Here is a quick drawing roughly indicating front and rear while showing firebox in relation to the water jacket.

Like your fan issue, water movement & heat transfer inside the boiler will likely be a fuzzy picture until you actually get burning with it. I think the locations you are planning for supply & return are the best for those purposes - but you also might end up needing to install a separate mixing pump to prevent localized boiling at possible hot spots above the firebox. I can picture there not being a lot of water movement in the top front part of your water jacket. Your system flows etc. will also play a part - so if you can plan for that eventuality now, adding a second pump later will be easy. Maybe extra ports top front & bottom rear? I know I have heard of guys with Garns adding secondary mixing pumps - they generate a LOT of heat in a big hurry though.