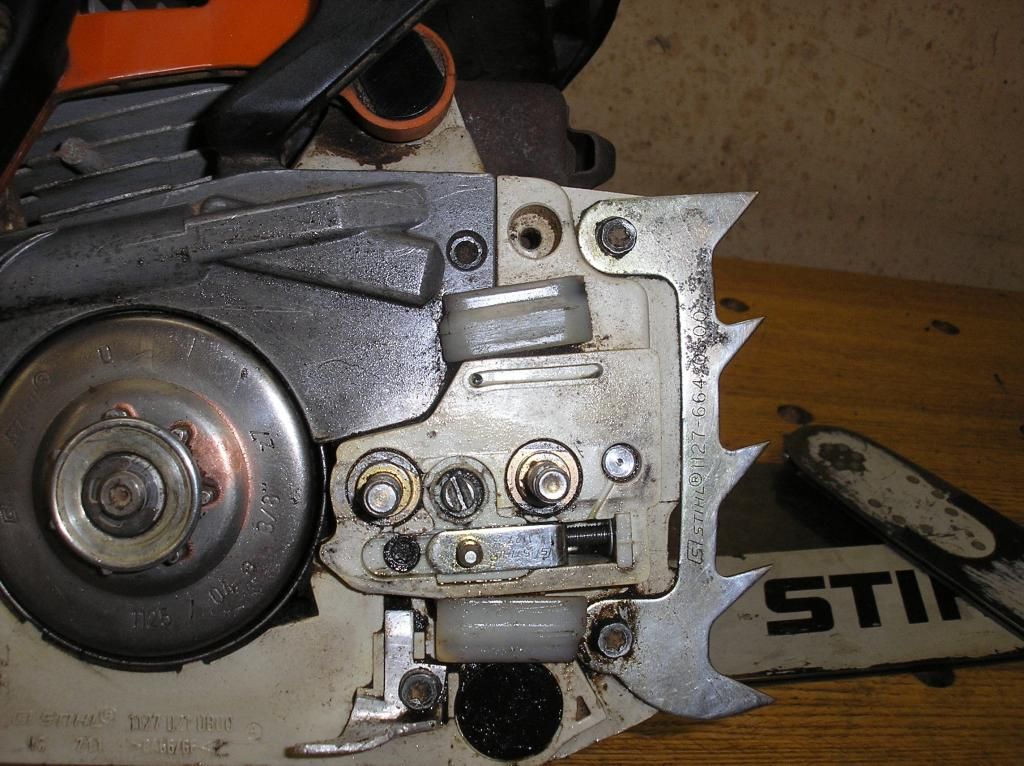

I ran into this issue with a Stihl MS290. Thousands of saws could be affected by it in addition to the 290, so I decided to post it. The oil hole on the Rollomatic ES bar does not line up with the housing slot and port fed by the oil pump. It's off by half the diameter of the hole. The slot in the saw's housing is positioned that much too low. That means that only half of the oil flow from the saw's pump is being allowed into the bar.

I checked the same bar against the slot on my MS361. It lines up much better, so I imagine the same bar could be used on the MS361, but not enough oil makes it to this bar when used on the MS290. This situation, of course, is worsened by cold weather when thicker oil has to be pumped.

To correct the problem I figure I have two options. First, drill out the holes larger on the bar on both sides so that more oil can be accepted from the pump. I figure about a 3/16" dia. hole might solve it. Second, I could carefully scrape the slot wider on the housing. However, that slot already has a very narrow upper shoulder and to widen it along it's entire length might be precarious.

What do you recommend?

I checked the same bar against the slot on my MS361. It lines up much better, so I imagine the same bar could be used on the MS361, but not enough oil makes it to this bar when used on the MS290. This situation, of course, is worsened by cold weather when thicker oil has to be pumped.

To correct the problem I figure I have two options. First, drill out the holes larger on the bar on both sides so that more oil can be accepted from the pump. I figure about a 3/16" dia. hole might solve it. Second, I could carefully scrape the slot wider on the housing. However, that slot already has a very narrow upper shoulder and to widen it along it's entire length might be precarious.

What do you recommend?