Let's take a stab at this. But I gotta watch out for the lurker pros (humbolts:soldier

waiting for the chance to virtual flame. Here goes:

We've used cat stoves since Vermont Castings introduced them as part of an engineered wood stove in 1989. Like the ones in your truck, they have a limited life.

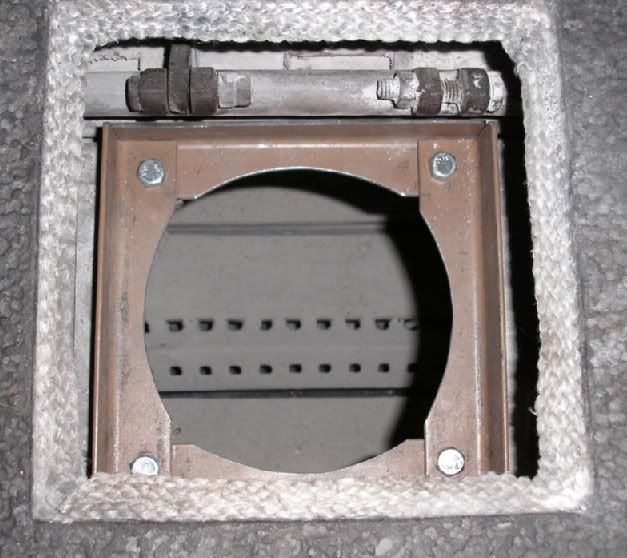

The ceramic catalysts last for about 12,000 hours ( +/- 2 years of 24/7 hard use) before the paladium or platinum coating wears off and/or the ceramic starts to crack.

I put in a steel cat last winter for our normal 2-3 season replacement. Good so far with just the usual brush-off cleaning. The company, Sud Chemie, says that the metal cat will "light off" at lower temps ( ~ 400 F ) and take higher temps without breaking up like the ceramic cats, and lst longer. We'll see.

So if your cat is well over the 12,000 hour life, replace it. Another way is to do the recommended (Corning) " vinegar bath" to restore the cat . A PITA.

We have a cat and non-cat stoves for heating. The cat stove holds a longer fire, use less wood for the same BTUs, and allow the stove to be damped way down overnight. Butt: cats demand more care and maintenance. Non cat stoves like our Oslo don't allow the air to be very low or very high---a mommie approach for clean burning.

Long way of saying: it's time to replace the cat if it's been in for a few years and used hard. To check the cat operation, get the stove hot ( 600-700 F on top), damper in the cat, then let the temp go back up before lowering the primary air. Then run outside (clothes on). If you see dark smoke, the cat isn't working.