skid row

ArboristSite Guru

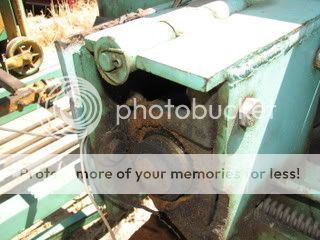

This guy built this two cylinder diesel powered bandsaw. The saw is pulled along the trailer by a chain connected to a gear motor.

He takes it to some shows to let people see how it works. They are milling tulip poplar. As the lumber comes off the mill they are using it to build a nice shed on the left.