David (saltas)

Addicted to ArboristSite

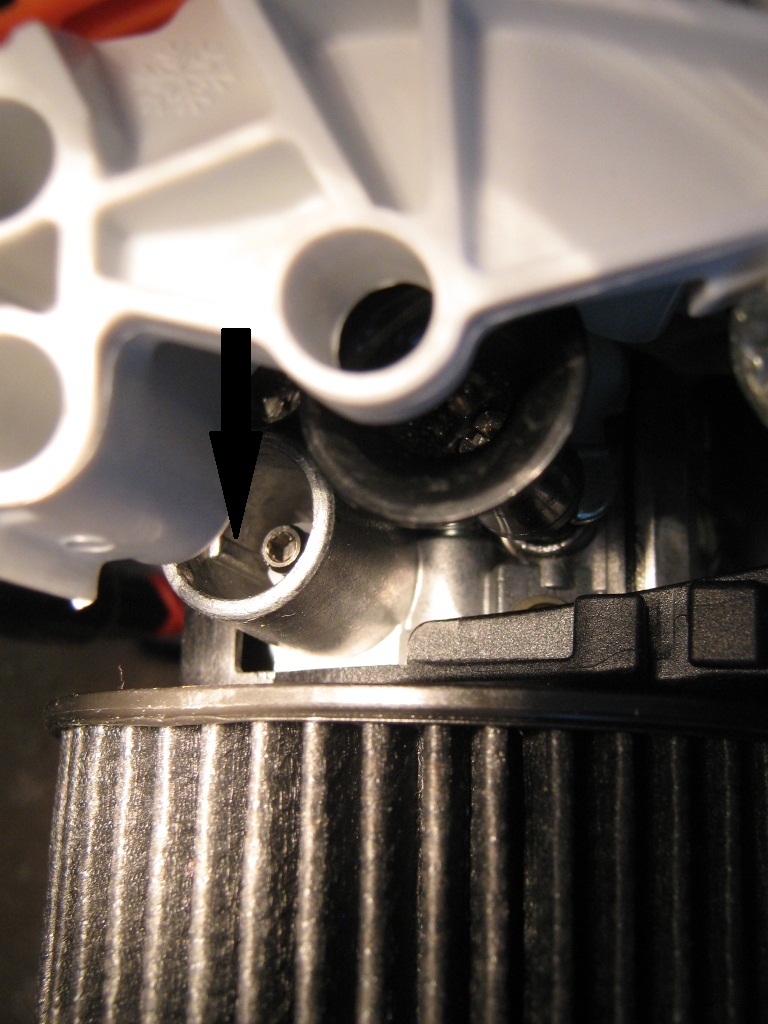

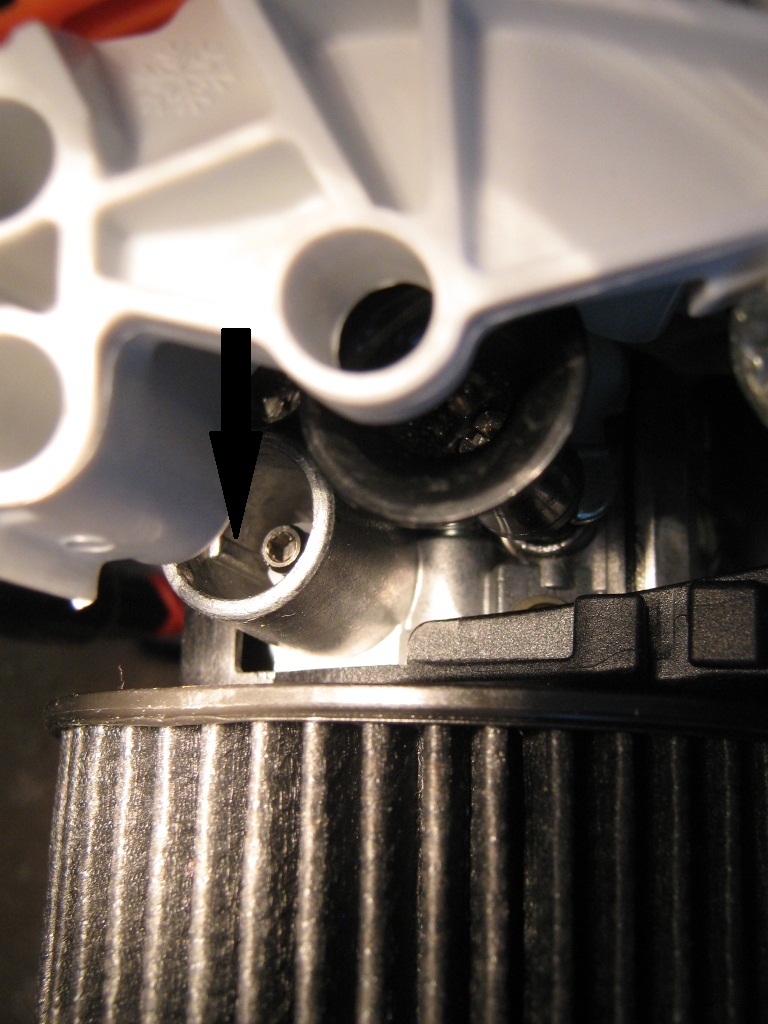

I read many threads and was confident I could do the job of removing the H Limiter tabs

The MS 261 has an Alloy H limiter and it comes out with a dry wall screw as described by many others on here.

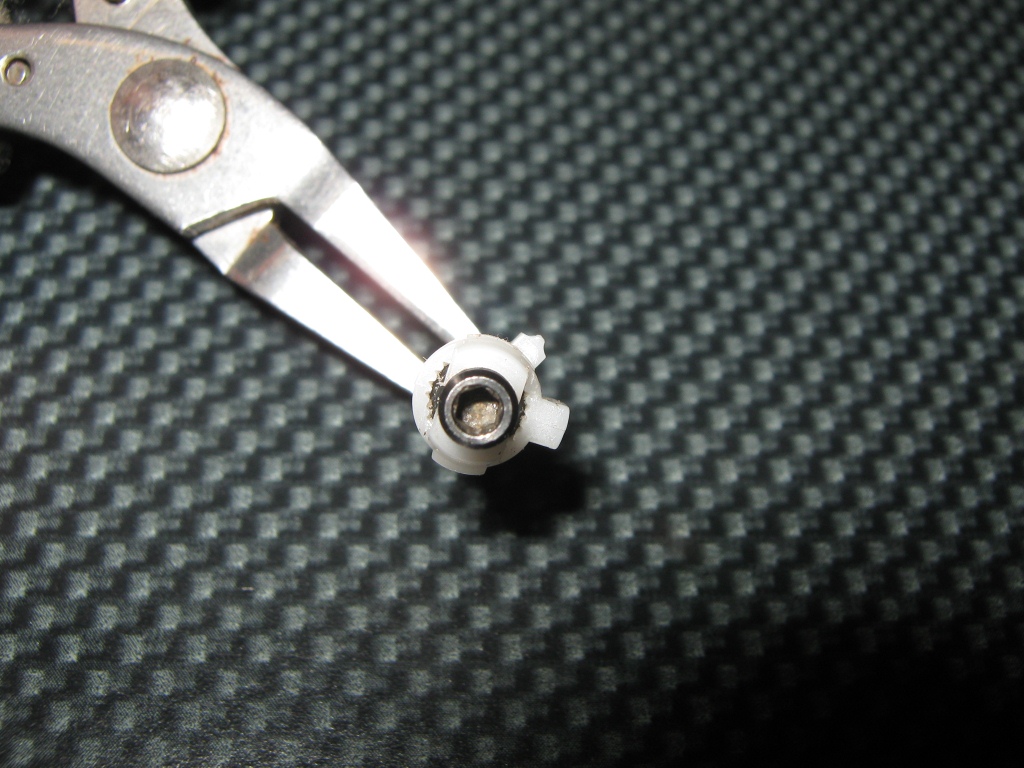

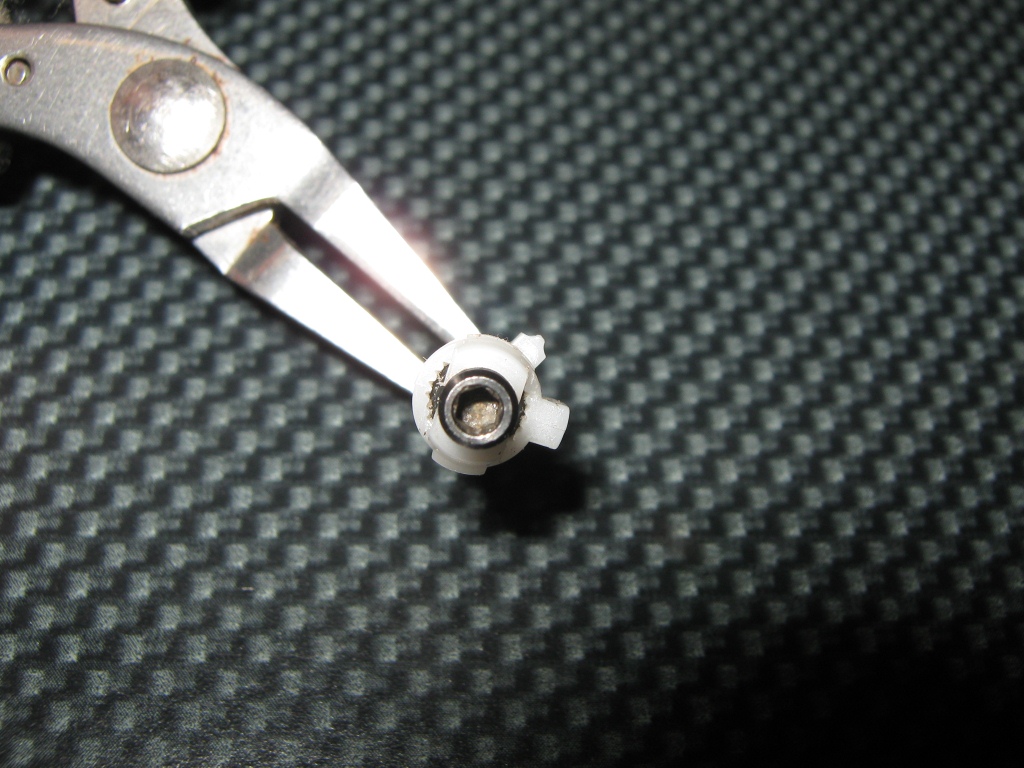

Alloy was no problem just used a file instead.

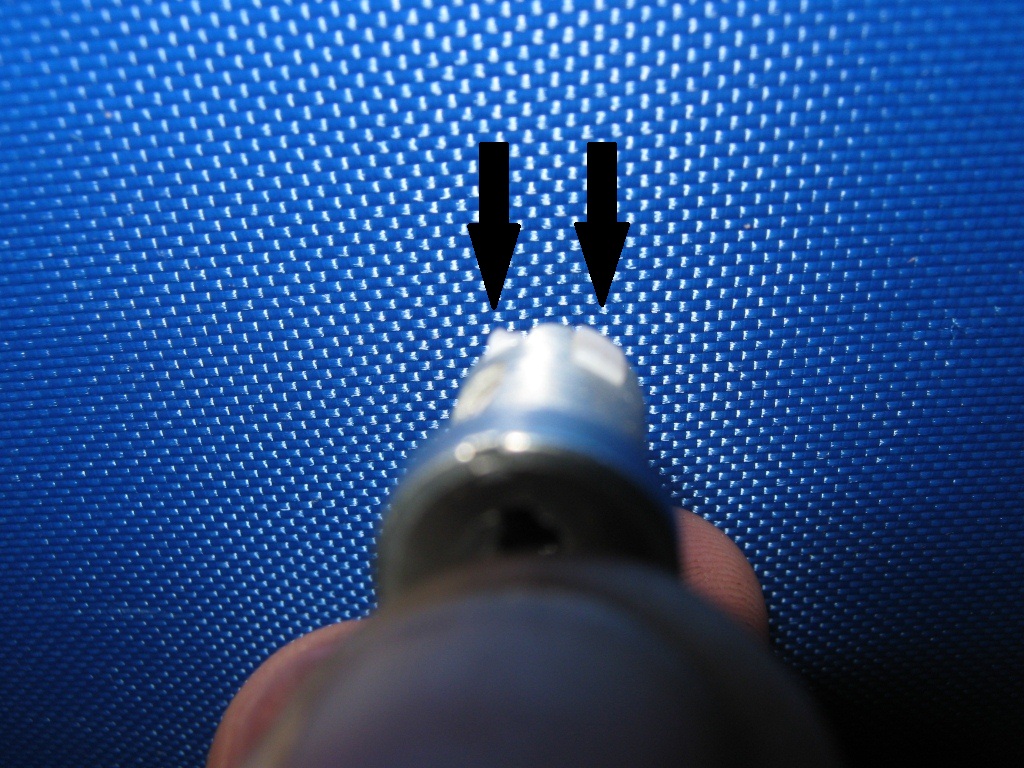

MS261 alloy H Limiter with rib filed off

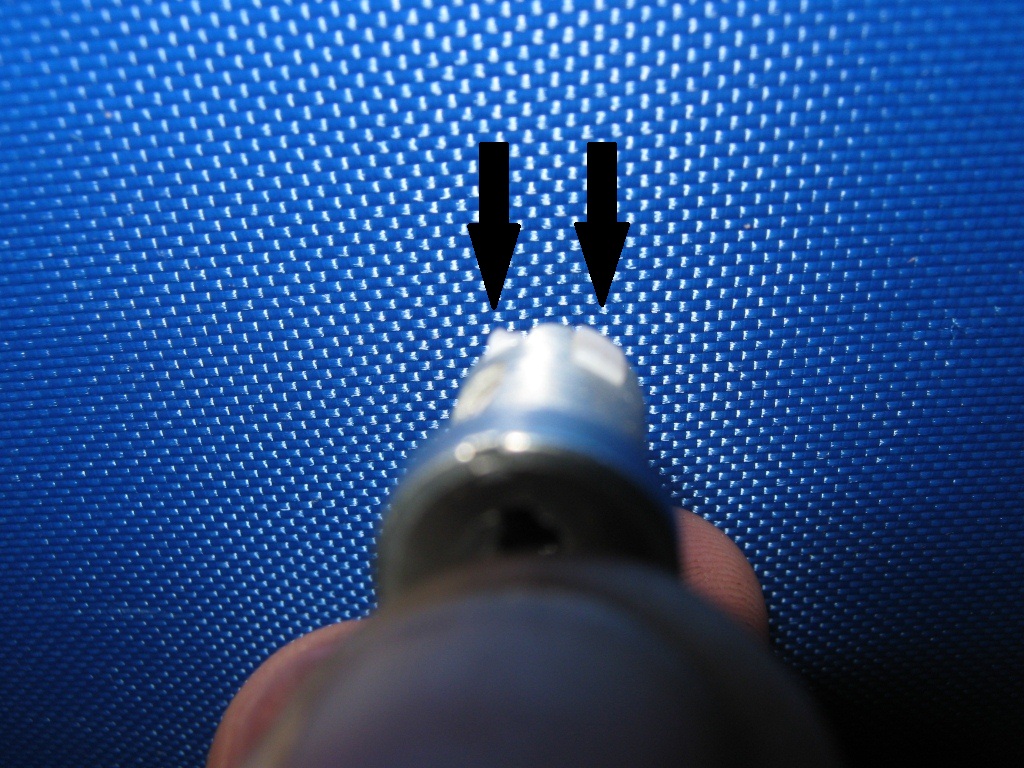

MS261 High speed adjustment screw whole internal rib.

Installed the Alloy H limiter and it still had the same range of motion as before ?

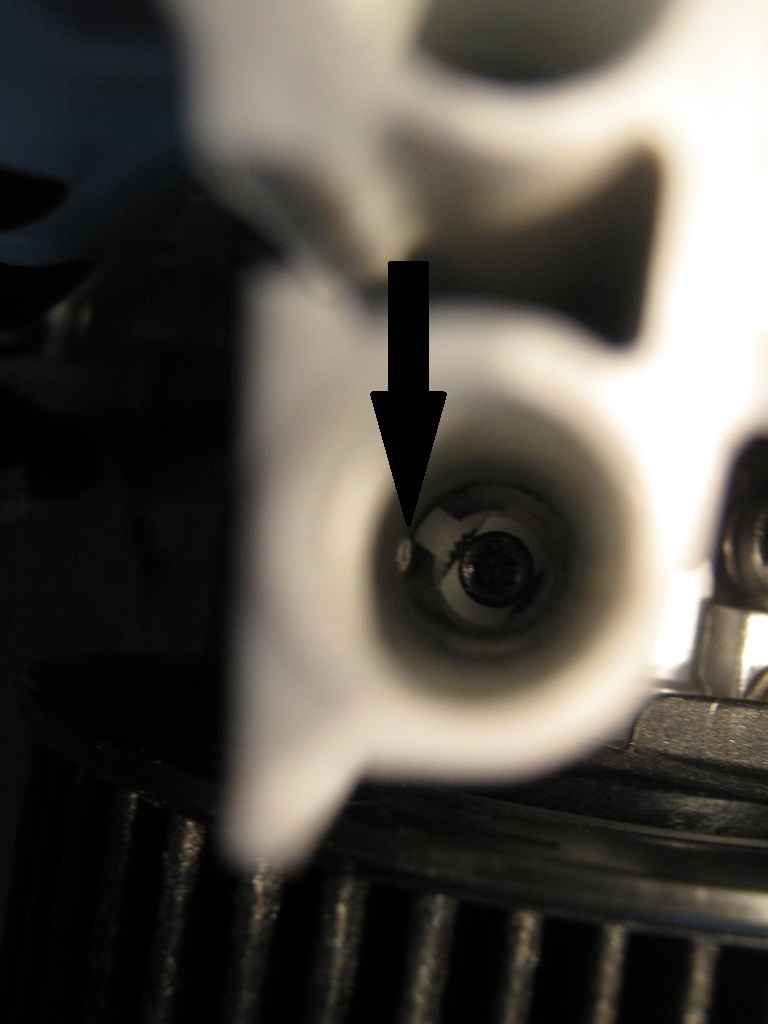

Pull it apart

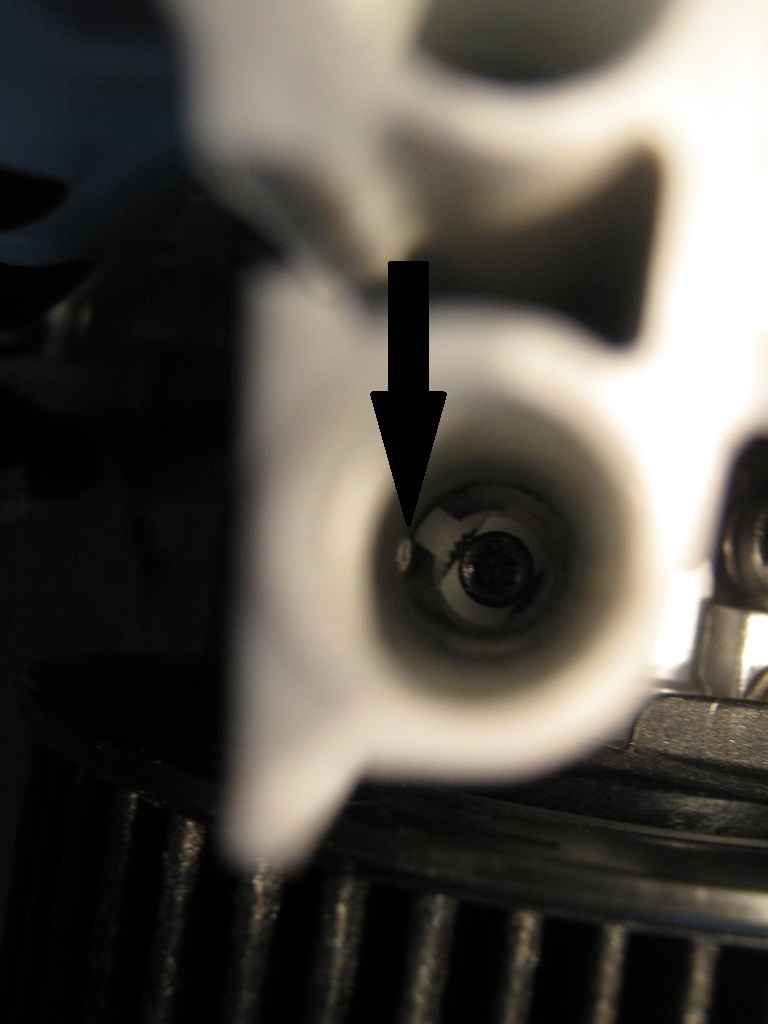

MS261 High speed adjustment screw plastic insert still hitting internal Rib

So I removed the High speed adjustment screw

I placed in side the alloy H limiter and the two plastic tabs were proud of the surface of the alloy so I trimmed these with a sharp knife.

I installed the High speed adjustment screw and then inserted the H limiter after it and was able to get the adjustment I wanted.

I have set it at 13440 rpm WOT for now and will try it in some wood soon

The MS 261 has an Alloy H limiter and it comes out with a dry wall screw as described by many others on here.

Alloy was no problem just used a file instead.

MS261 alloy H Limiter with rib filed off

MS261 High speed adjustment screw whole internal rib.

Installed the Alloy H limiter and it still had the same range of motion as before ?

Pull it apart

MS261 High speed adjustment screw plastic insert still hitting internal Rib

So I removed the High speed adjustment screw

I placed in side the alloy H limiter and the two plastic tabs were proud of the surface of the alloy so I trimmed these with a sharp knife.

I installed the High speed adjustment screw and then inserted the H limiter after it and was able to get the adjustment I wanted.

I have set it at 13440 rpm WOT for now and will try it in some wood soon