JAXJEREMY

ArboristSite Operative

Pulled the saw apart today. The last time I used it was probably 2 years ago, so it was pretty filthy. I was digging through my boxes of stuff an found a carb rebuild kit for it that I had never put in.

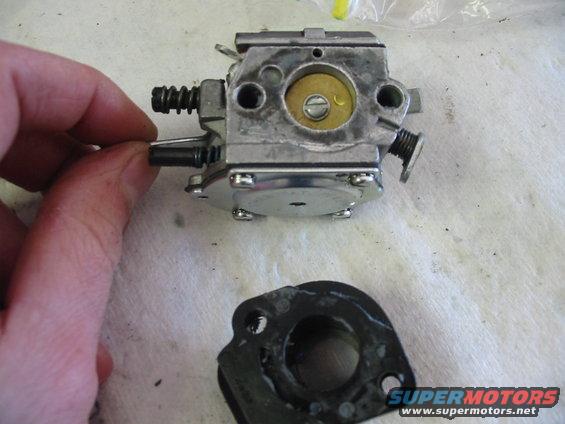

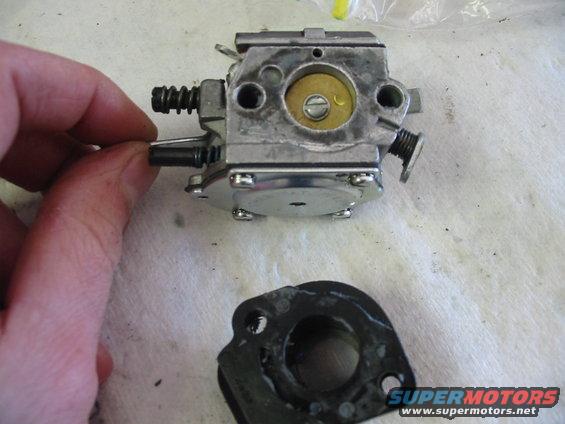

Turns out it is a Walbro.

I'm assuming I need a gasket for where the carb mounts to the casing, should I just use gasket maker?

Piston looked ok, didn't seem scorched or anything.

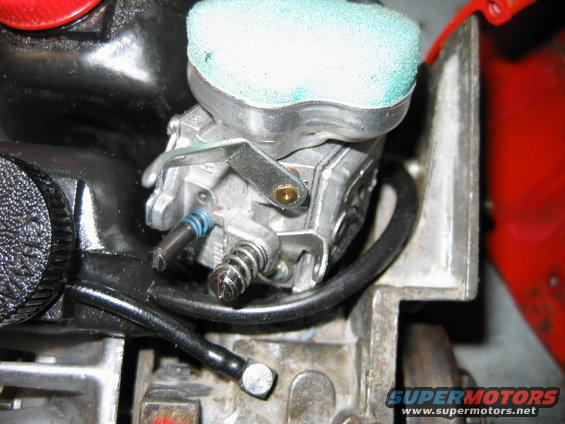

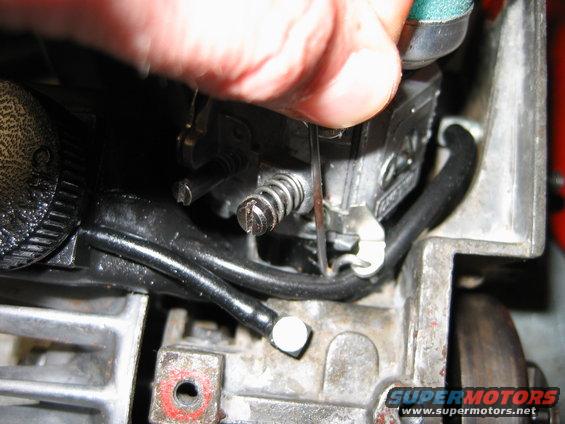

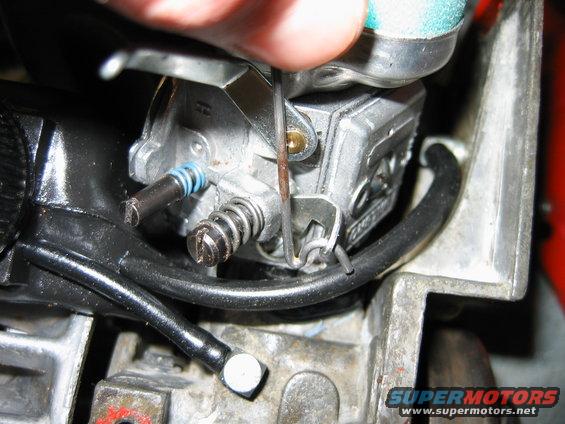

This is the carb after putting the new needle and gaskets in. Should there be some sort of gasket between that black plastic piece(not sure what it's called) and the carb?

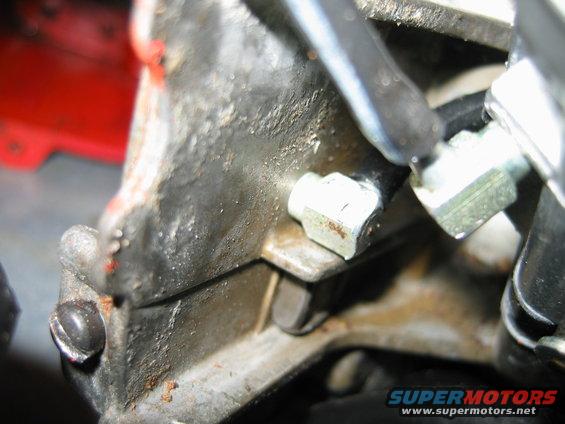

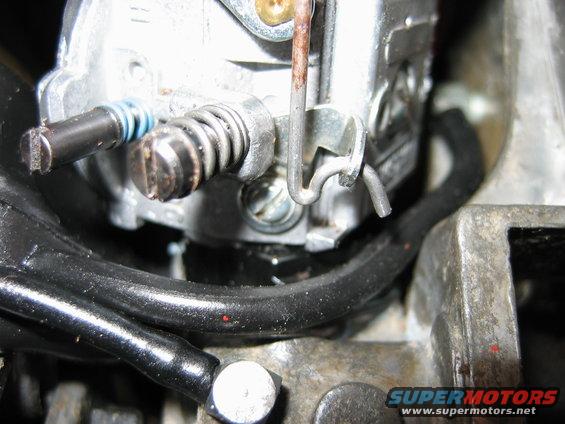

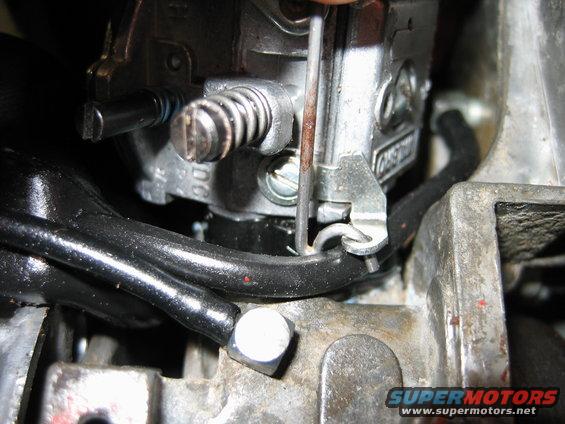

This is the duck bill valve that creates the pressure in the oil tank, when I open took it out, that piece made of the pourous material between the valve and the tubing was push all of the way in..I'm guessing that might have been part of my problem with the oil continuing to squirt out even after the saw was off.

I still need a filter and that's about it. Is there anything particular I need to do to adjust the carb? Thanks.

Turns out it is a Walbro.

I'm assuming I need a gasket for where the carb mounts to the casing, should I just use gasket maker?

Piston looked ok, didn't seem scorched or anything.

This is the carb after putting the new needle and gaskets in. Should there be some sort of gasket between that black plastic piece(not sure what it's called) and the carb?

This is the duck bill valve that creates the pressure in the oil tank, when I open took it out, that piece made of the pourous material between the valve and the tubing was push all of the way in..I'm guessing that might have been part of my problem with the oil continuing to squirt out even after the saw was off.

I still need a filter and that's about it. Is there anything particular I need to do to adjust the carb? Thanks.

)

)