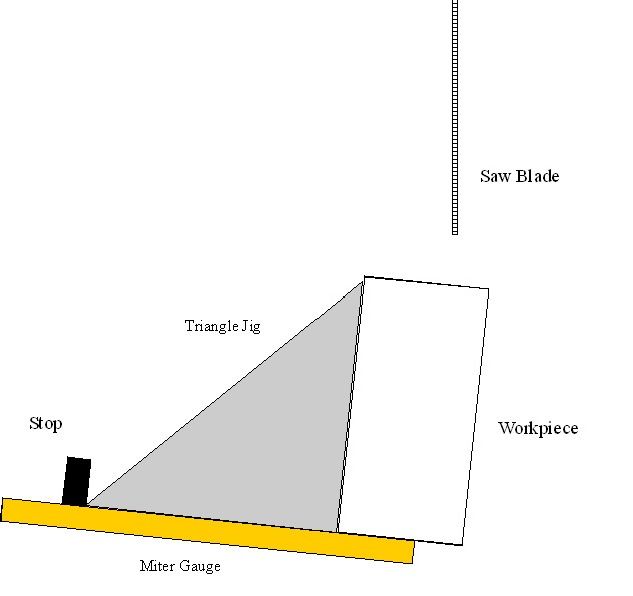

The other day I was staring at a rough cut chunk of oak leftover from a workbench I made. It was about 12" long, 8" wide and a full 2" thick. I decided to plane it down to 1-7/8" and see if I could make wedges with it for felling and bucking. I cut the wedges at a 6-degree angle, one right after the other using my table saw, its rip fence, and a taper cutting jig. After knocking off the outer sharp ends, two were about 10" long, two were 9" long, and the rest were about 8" long:

I sanded off the rough edges and rounded the tops a little. Here's another view of the collection:

At this point, you are probably saying, "Why the hole near the sharp end?" Well, one thing that happens to wedges is that they sometimes get lost. I decided that something that resembled a big key ring might help. I found two lengths of 3' round steel stock that I salvaged from a political yard sign and made a pair of helix coils, three turns apiece, by wrapping it around PVC drain pipe. The 1/4" countersunk holes allowed an easy thread onto the coil:

I made two sets and thought best to give one to my logging buddy who will probably use them more than I will as he fells and bucks lots of big stuff. Best thing about these wedges is that I can make replacements as they wear out. The stores want anywhere from $6 to $10 apiece for the plastic ones. Yeah, those may last longer, but I have a feeling these will work about as well and they are easy to keep together and hang on a pegboard hook.

Thanks for looking. WDYT?

I sanded off the rough edges and rounded the tops a little. Here's another view of the collection:

At this point, you are probably saying, "Why the hole near the sharp end?" Well, one thing that happens to wedges is that they sometimes get lost. I decided that something that resembled a big key ring might help. I found two lengths of 3' round steel stock that I salvaged from a political yard sign and made a pair of helix coils, three turns apiece, by wrapping it around PVC drain pipe. The 1/4" countersunk holes allowed an easy thread onto the coil:

I made two sets and thought best to give one to my logging buddy who will probably use them more than I will as he fells and bucks lots of big stuff. Best thing about these wedges is that I can make replacements as they wear out. The stores want anywhere from $6 to $10 apiece for the plastic ones. Yeah, those may last longer, but I have a feeling these will work about as well and they are easy to keep together and hang on a pegboard hook.

Thanks for looking. WDYT?