Multifaceted

Firewood Hoarder, Axe Enthusiast

I've searched these forums and elsewhere in the past few months for info on this old saw, and thus far it's been helpful. I'm trying to get this little old saw running reliably again. I have no other use for it, but it was my late father's, who neglected it for the past twenty or so years, probably longer. I want to get it running again, reliably, just to have my old man's saw working, no other reason. When it was being used, it probably only saw maybe 2-3 hours of runtime, so the saw is really only old and has been sitting. The piston head has some fouling, but otherwise seems in good order.

When I found it, the bar was bent and rusted, as was the chain. I got it home, replaced the spark plug, air filter and filled it with fresh gas (50:1). After a few pulls with starting fluid, she fired up and stayed running. Got the carb tuned enough to actually do some work, but it was still running erratic, and was leaking fuel. I ended up disassembling it to replace the fuel line, only to get frustrated with the carb adjustments again and ordered a car rebuilt kit. I then disassembled it again, replaced all of the diaphragms and gaskets, metering lever/needle/spring, and gave the carb a thorough cleaning with carb cleaner and compressed air. In hindsight, I probably should have soaked the metal parts in acetone overnight before reassembling...

After doing all of that, the old girl starts, but stalls out in idle. I've tried resetting and adjusting the hi/lo needles and idle screws to no avail, she starts, runs with the throttle open for a bit, but then stalls out. Sounds throaty, somewhat four stroking, so nothing appears (in my limited experience with 2 stroke engines) to be off. I'm pretty sure I reassembled the carb correctly, but I might need to adjust the height of the metering lever, and I'm thinking of completely overhauling the carb and soaking all of the metal parts in acetone, and the plastic parts in soapy water. The manuals I have found state that it ran McCullouch special 40:1 fuel mixture, but I've been running 50:1 as my other old 2 stroke engines run that fuel ratio well, I just have to regularly clean the spark plugs from fouling up. Should I be running a different fuel/oil ratio?

Does anyone else have any more recommendations on these little old saws? If you have one, then you know how much of a PITA it is to take it all apart, reassemble it just to find out something is still off... Very frustrating saw to work on, but it was my dad's, so I want to put it back in use again.

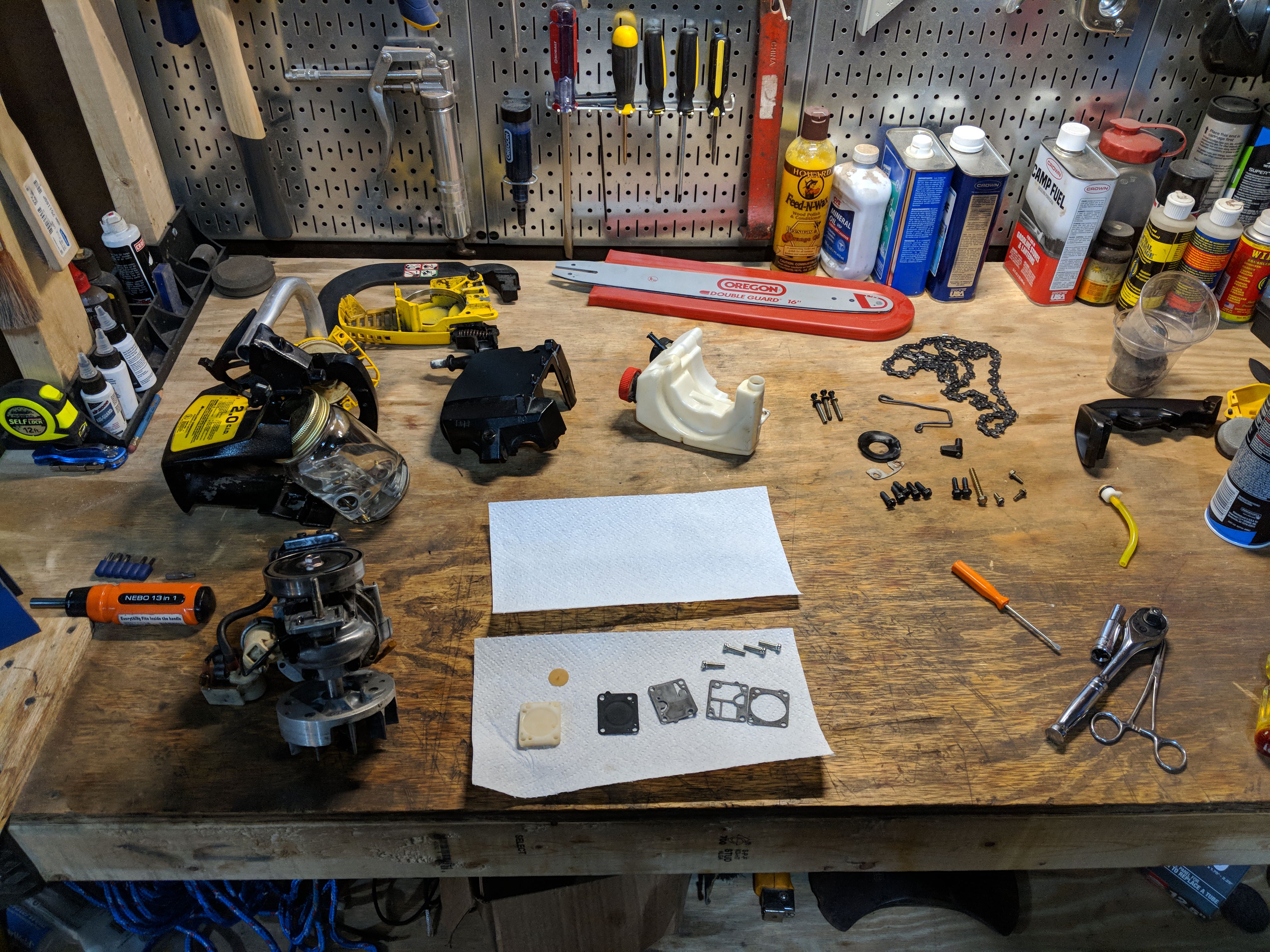

Here's pics:

When I found it, the bar was bent and rusted, as was the chain. I got it home, replaced the spark plug, air filter and filled it with fresh gas (50:1). After a few pulls with starting fluid, she fired up and stayed running. Got the carb tuned enough to actually do some work, but it was still running erratic, and was leaking fuel. I ended up disassembling it to replace the fuel line, only to get frustrated with the carb adjustments again and ordered a car rebuilt kit. I then disassembled it again, replaced all of the diaphragms and gaskets, metering lever/needle/spring, and gave the carb a thorough cleaning with carb cleaner and compressed air. In hindsight, I probably should have soaked the metal parts in acetone overnight before reassembling...

After doing all of that, the old girl starts, but stalls out in idle. I've tried resetting and adjusting the hi/lo needles and idle screws to no avail, she starts, runs with the throttle open for a bit, but then stalls out. Sounds throaty, somewhat four stroking, so nothing appears (in my limited experience with 2 stroke engines) to be off. I'm pretty sure I reassembled the carb correctly, but I might need to adjust the height of the metering lever, and I'm thinking of completely overhauling the carb and soaking all of the metal parts in acetone, and the plastic parts in soapy water. The manuals I have found state that it ran McCullouch special 40:1 fuel mixture, but I've been running 50:1 as my other old 2 stroke engines run that fuel ratio well, I just have to regularly clean the spark plugs from fouling up. Should I be running a different fuel/oil ratio?

Does anyone else have any more recommendations on these little old saws? If you have one, then you know how much of a PITA it is to take it all apart, reassemble it just to find out something is still off... Very frustrating saw to work on, but it was my dad's, so I want to put it back in use again.

Here's pics: