landfakers

ArboristSite Operative

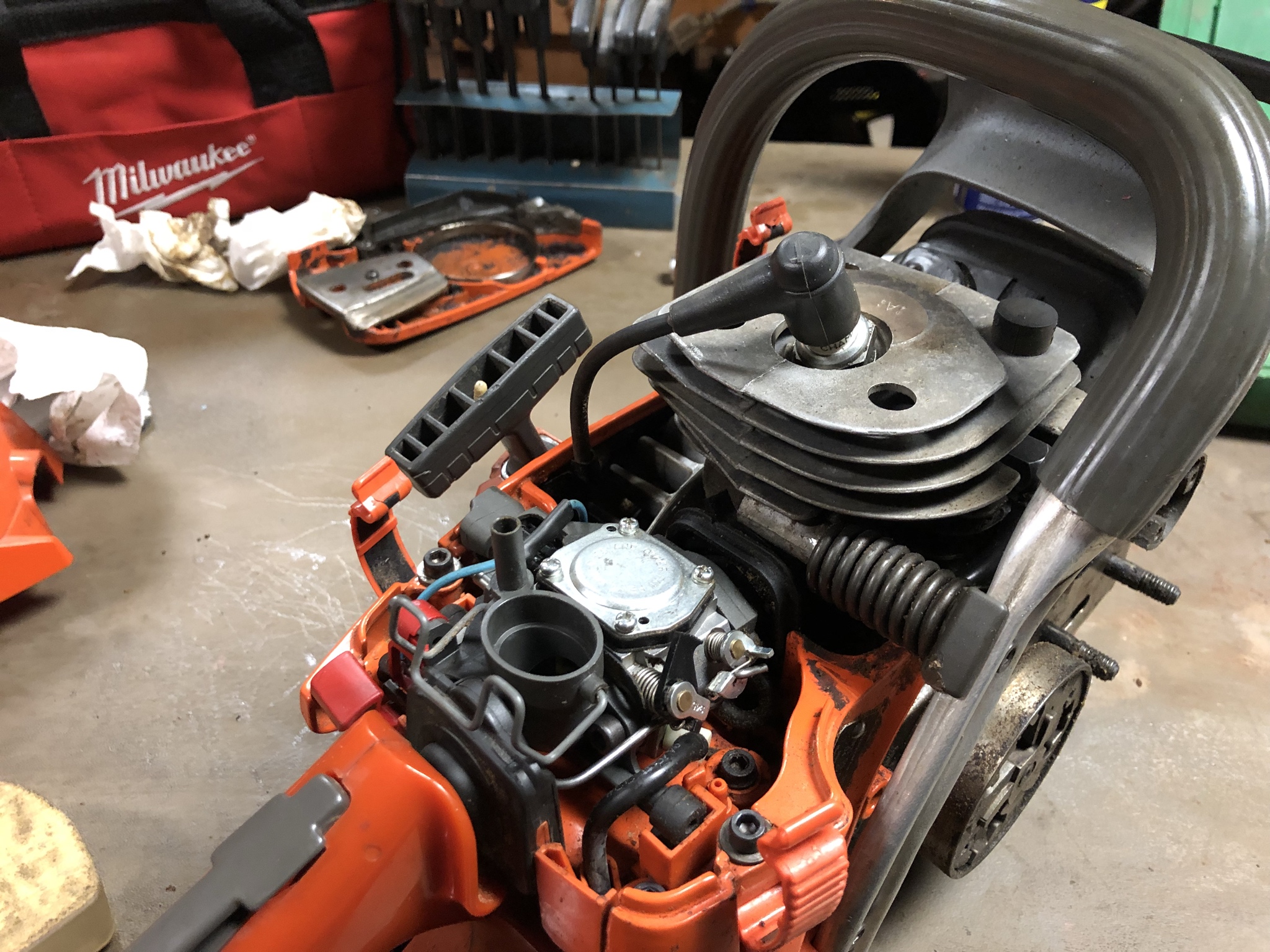

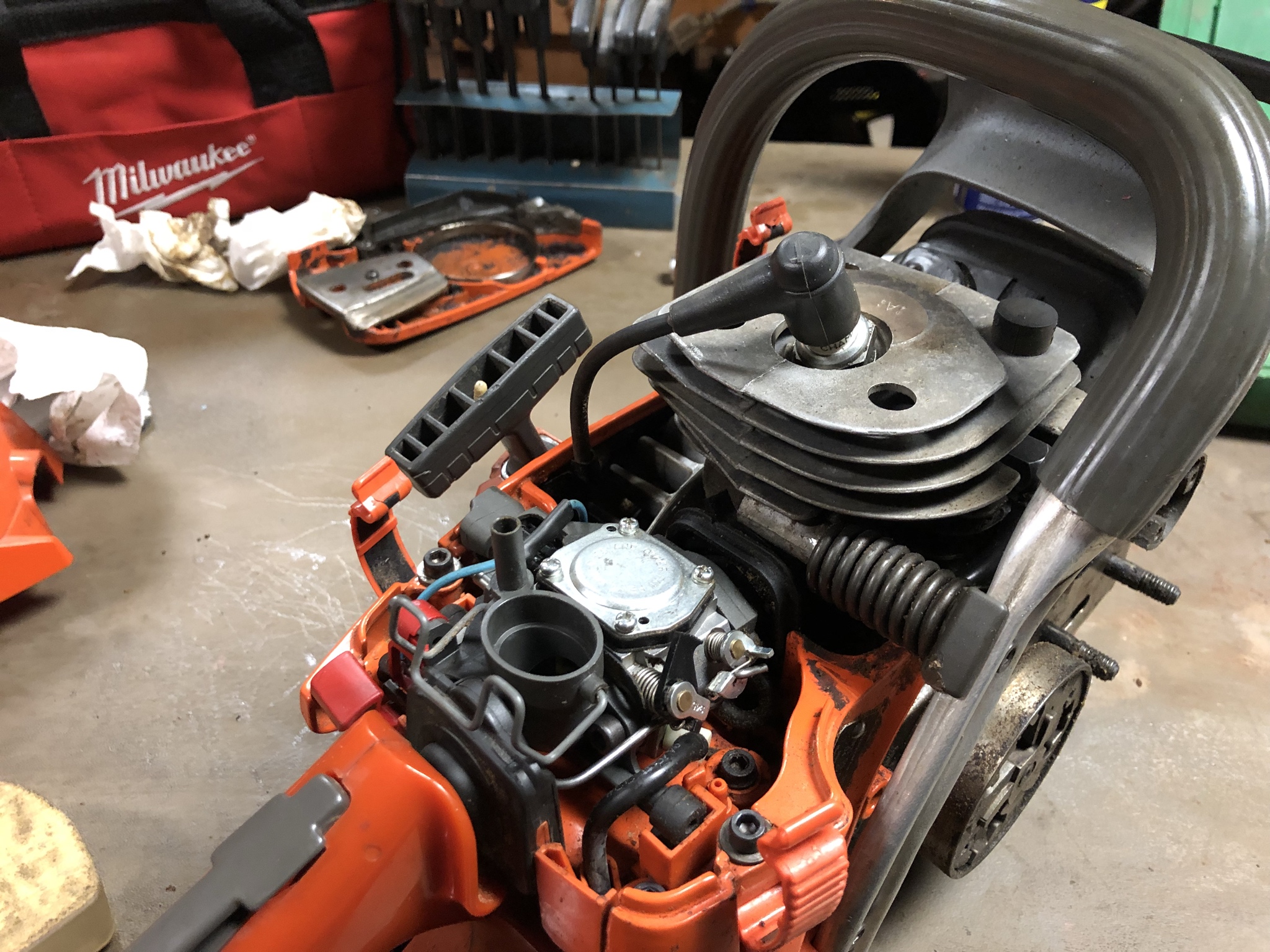

Coworker surprised me this morning and gave me a 357xp for free that he had gotten from a neighbor. He had no use for it so I was happy to take it from him. It is in pretty good shape, but hasnt been run in 5+ years from the sounds of it. It is a 2004 model, with the 199A carb. I started by popping off the carb just to get a look at the piston and it looks good from what I can see. Tried to run a compression test and only came out with 40psi, but im thinking this has to do with the dumb auto decomp? I pulled it off and dont have much of an idea of what im looking at or how to possibly test it. Also found this(1st picture) lodged in the rubber line No idea what that is.

No idea what that is.

I've already decided that I will be installing a manual decomp valve, and read that the Walboro 199A carbs are somewhat troublesome, so looking into a zama carb, but should I pull the cylinder and have a look before I go and order those things? Im guessing the answer is yes. I am pretty good mechanically and taking the carb out was easy, just want to get some opinions on going about this the right way

Thanks guys

I've already decided that I will be installing a manual decomp valve, and read that the Walboro 199A carbs are somewhat troublesome, so looking into a zama carb, but should I pull the cylinder and have a look before I go and order those things? Im guessing the answer is yes. I am pretty good mechanically and taking the carb out was easy, just want to get some opinions on going about this the right way

Thanks guys