Just thinking of handles, it brings me to my pet peeve with ebay sellers. I've noticed a few big ax sellers, that cut the handles off every ax they have. I can't believe that none of the original handles survived, especially when some of the heads are mint. I just went downstairs and took a quick look at the wall mount with my favorite axes hanging from it. Number 1 is, my Dad's Collins Legitimus double, that still has the original finish on the handle, and the words "Genuine Collins Hickory". My wife's grandfathers American Beauty. It has white surgical tape wrapped around it a few inches up from the head. Obviously, not to protect the head, but for grip. We used to use the same tape on our Lacrosse sticks. I have a Dunlap boys ax with a white painted handle. It's a little chipped at the front of the eye, still very serviceable. Somewhere I picked up a nice 4 pound Jersey with the original handle, painted a dark red. It was my favorite, of the moment, splitting ax. Worked great on straight grained Oak. That's all I would use it on, trying not to stress it. A few months ago I had a big block of Ash that I thought would pop right in half. The handle sheared off right at the head. Not a mark or ding on it, I guess just dry rotted. Anyway, I'd never cut a serviceable handle off. But, I guess there are enough collectors out there who just like to look at them on a shelf. I understand that, I just think they look better with a chunk of wood on them.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Axe restoration thread

- Thread starter svk

- Start date

Help Support Arborist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

One of these days I’ll finish my coat/hat rack for the cabin. It will be a matching piece of Fir as my ax board, with small ball peen hammer heads for the hooks. I used to see boxes of them at farm auctions and they couldn’t give them away. Now that I’m looking for them, they turned into the proverbial hens teeth.These hammers are looking grungy. As soon as I find my jug of BLO I’ll refinish them along with whatever other tools that need a coat.

The one on the left came with something I bought (maybe my old boat?) and the one on the right is an heirloom from my grandpa.

View attachment 823408

If I see any heads I’ll grab them for you.One of these days I’ll finish my coat/hat rack for the cabin. It will be a matching piece of Fir as my ax board, with small ball peen hammer heads for the hooks. I used to see boxes of them at farm auctions and they couldn’t give them away. Now that I’m looking for them, they turned into the proverbial hens teeth.

I think I have three or four ball peen hammers in the lineup. The nice thing is they never seem to go missing (go figure) so if I need a hammer they are always in the tool shed. The claw hammers always get left somewhere in the garage, usually forgotten after a project. Sometimes I have 8 and sometimes I have none.

The ones I was looking for are little ones, I think they are 2-3 ounces. I could always mix sizes. I think I'll pick out the board tomorrow and put a couple coats of BLO on it.

Chris Cringle

ArboristSite Lurker

My apologies if this has been covered already and I simply wasn’t finding it by browsing the site and using the search engine.

I have several splitting mauls of different weights and profiles. I try to keep the striking edges neat so that they bite sufficiently. Nothing close to sharp. I sharpen them with a bastard file from time to time, again, just to sharpen up flat spots where I struck something hard or the flared metal around nicks. I usually don’t file all the way down to the deepest part of nick because I don’t want to be removing that much metal that quickly. I just satisfy myself with removing the tabs of metal that stick out sideways from the head around the nick.

My question is, do you think I can use a bench grinder or a grinding stone drillbit and power drill for any of this? I tend to not sharpen things with high speed power tools out of concern for heating up the metal too much and degrading it’s hardness. But I am not sure about this which is why I am writing. Thanks in advance for any comments.

I have several splitting mauls of different weights and profiles. I try to keep the striking edges neat so that they bite sufficiently. Nothing close to sharp. I sharpen them with a bastard file from time to time, again, just to sharpen up flat spots where I struck something hard or the flared metal around nicks. I usually don’t file all the way down to the deepest part of nick because I don’t want to be removing that much metal that quickly. I just satisfy myself with removing the tabs of metal that stick out sideways from the head around the nick.

My question is, do you think I can use a bench grinder or a grinding stone drillbit and power drill for any of this? I tend to not sharpen things with high speed power tools out of concern for heating up the metal too much and degrading it’s hardness. But I am not sure about this which is why I am writing. Thanks in advance for any comments.

I'll use a flapwheel grinding pad on my grinder to profile an edge but am very careful to keep the steel cool so I don't change the temper .

U&A

Addicted to ArboristSite

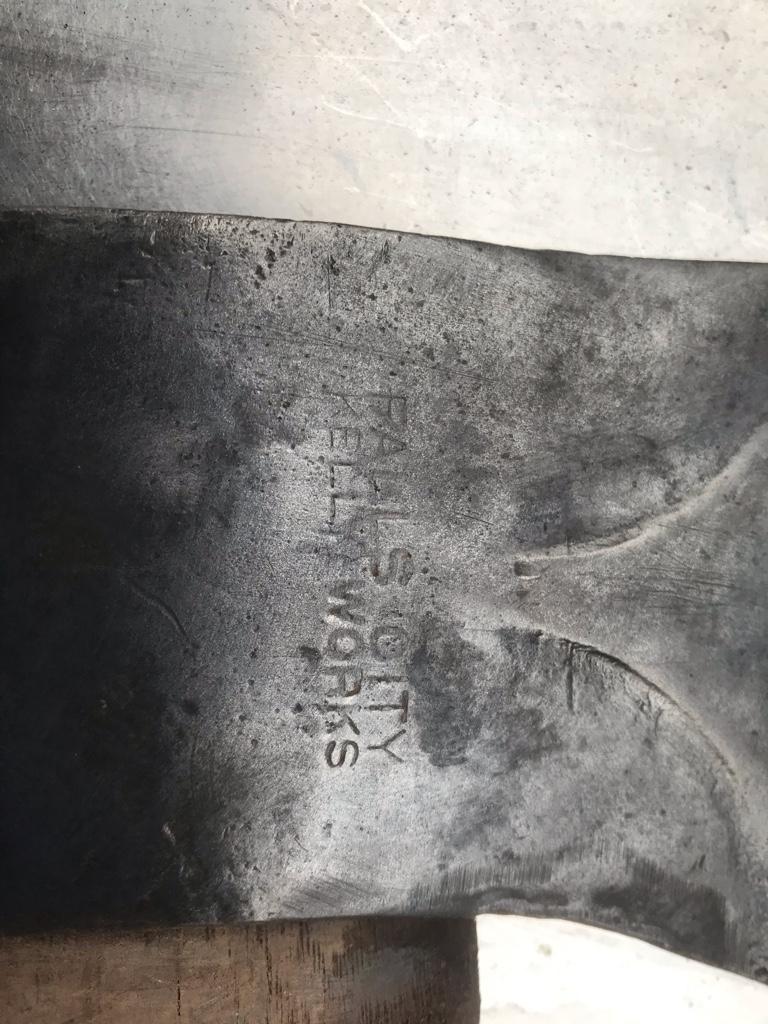

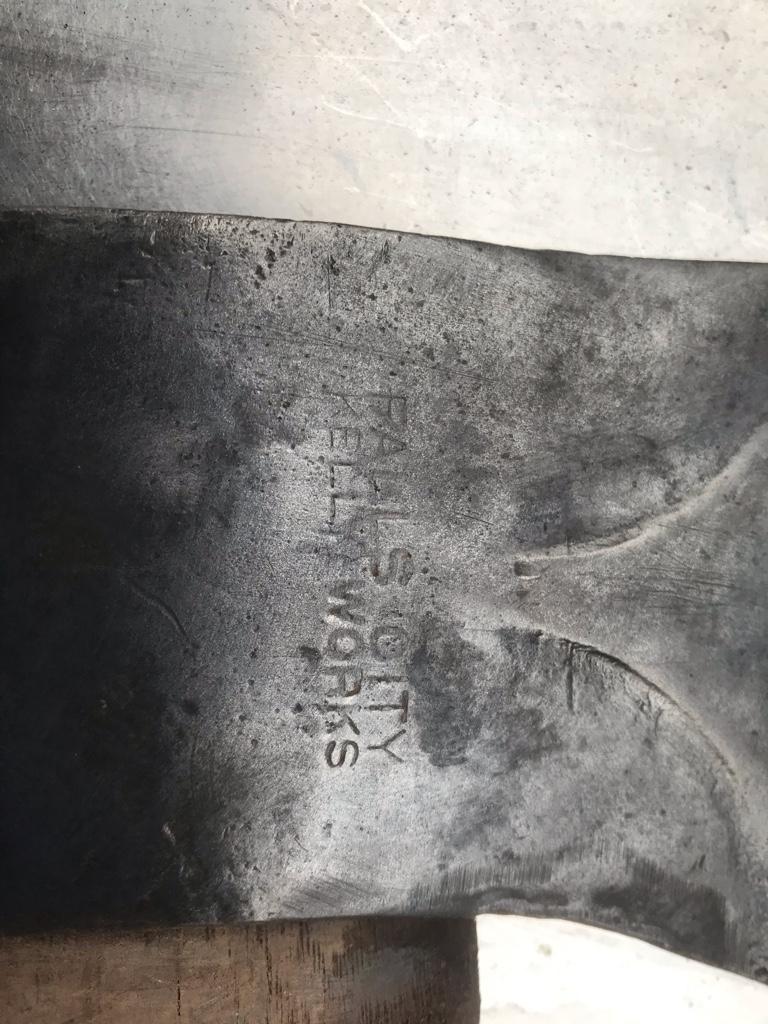

Some freebies today. Cleaned up the axe with a wire wheel to find the name. Some took a grinder to it kinda bad. That really thick rusty head is odd looking. Any ideas on what it was for? Just a different kind of maul ?

Sent while firmly grasping my redline lubed RAM [emoji231]

Sent while firmly grasping my redline lubed RAM [emoji231]

I have been checking in on this thread occasionally and enjoy seeing the restorations. Coincidentally I was at my mom’s today and came across a similar head...decided to bring it back to life and it will be fun restoring something I know was my dad’s. Does this take the “standard” handle if there is such a thing? Found another gem that brought back memories, going on the wall in my saw area.Got the surface rust off and hit it with a coat of oil right away to prevent any additional rust.

View attachment 588902

nathan4104

ArboristSite Operative

i've been watching for a while and finally got around to digging out a few old axe heads.....

First is a Walter. It's rather heavy feeling, probably 5 pounds?

second has no name but came from the dumpster at work. Apparently it's not safe for forest fire crews to replace handles anymore. When the picking is good there are Ox heads in the trash.....

The Walter needs a new handle i'll get to that later.

Now to finish this job...

First is a Walter. It's rather heavy feeling, probably 5 pounds?

second has no name but came from the dumpster at work. Apparently it's not safe for forest fire crews to replace handles anymore. When the picking is good there are Ox heads in the trash.....

The Walter needs a new handle i'll get to that later.

Now to finish this job...

Attachments

I'm with Dan, I use a flap disk on my DeWalt angle grinder.My apologies if this has been covered already and I simply wasn’t finding it by browsing the site and using the search engine.

I have several splitting mauls of different weights and profiles. I try to keep the striking edges neat so that they bite sufficiently. Nothing close to sharp. I sharpen them with a bastard file from time to time, again, just to sharpen up flat spots where I struck something hard or the flared metal around nicks. I usually don’t file all the way down to the deepest part of nick because I don’t want to be removing that much metal that quickly. I just satisfy myself with removing the tabs of metal that stick out sideways from the head around the nick.

My question is, do you think I can use a bench grinder or a grinding stone drillbit and power drill for any of this? I tend to not sharpen things with high speed power tools out of concern for heating up the metal too much and degrading it’s hardness. But I am not sure about this which is why I am writing. Thanks in advance for any comments.

cuinrearview

Red saw lover

I've got a hatchet that I really like the feel of that lost the wedge recently. I call it a hatchet but it's kind of big for a hatchet. The head is heavy and the haft is longer and skinny. I would say it's 18-20". My son said his friend makes handles and will hang it. I told him I would provide some heart wood from a hickory I recently cut up. Then I read conflicting opinions on heart vs. sap wood. It was only a 20" dbh tree so not old growth. What do the experts say?

U&A, nice looking Kelly works!

Nathan, ox in the rubbish!? Ox are superb quality. The stihl stuff is made by them (it has the ox head marking). I've a stihl Pro maul/cleaving hammer that I got brand new and very cheap on eBay as the seller didn't realise it wasn't the standard maul which is about 1/3 the price. It's a beast.

Cu, I've a similar hatchet. Dan the amazing gifted me the head. It needed a lot of work to get it hung well but as it is just over 1 1/2 lbs I put it on a longer handle, 21-22" smedberg. Been using it loads over the last week as I cut back some over grown stuff. It's a good size as it's small enough to swing single handed just, and large enough to slice Clean through 2.5" oak branches. Thanks again Dan, I love it.

Nathan, ox in the rubbish!? Ox are superb quality. The stihl stuff is made by them (it has the ox head marking). I've a stihl Pro maul/cleaving hammer that I got brand new and very cheap on eBay as the seller didn't realise it wasn't the standard maul which is about 1/3 the price. It's a beast.

Cu, I've a similar hatchet. Dan the amazing gifted me the head. It needed a lot of work to get it hung well but as it is just over 1 1/2 lbs I put it on a longer handle, 21-22" smedberg. Been using it loads over the last week as I cut back some over grown stuff. It's a good size as it's small enough to swing single handed just, and large enough to slice Clean through 2.5" oak branches. Thanks again Dan, I love it.

Okay, 'experts assemble!' or maybe not....'Bodgers assemble!'

as you know I got hold of a pretty nice 4.5lb Hult Bruk head a while ago and have done nothing with it as its got an unusually large eye, the right length but about 1 and 3/8" wide! I have pondered if it were made with the long size of eye that exists in Europe and had been pounded on the poll and deformed but I find that unlikely as the eye shape looks uniform and right, just too big for any regular handle. So... I ordered 2 Pick axe handles in Ash. 2 as...well I was buying on line and they were cheap, 2 would allow some selection. both tight grained and no hearthwood, both straight enough although one slightly S-shaped (right one)

so one (left) loos really rather good! which balances out against the stick of firewood on the right.

a closer look

next I select ....the firewood on the right....as I think I may as well practice this hang on the rubbish handle

I drew a line to mark the depth of the head a the eye, i did allow for a small protrusion at the top, but not much. the perspective misrepresents that

Ah ha! i have over come the width issue, yay!

but introduced a length issue....hmm...that can be overcome more easily though.....can't it?

let's tale a look from another angle.... view through...nose of the eye is maybe 1/8" 'on' so once seated down on the handle which tapers heavily (as pick axes, like tomahawks, are friction fit) there shouldn't be a gap, but there won't be material to remove either. back has a good 1/8" gap against the top of th handle, so once seated down the a gap will be a good 1/4 inch.

So I drew another line or 3. Axis line sketched by eye, 'P' for 'Poor' handle and the material to remove.

and from another angle... yes looks about right at the nose.

Right so my question. before i take my freshly sharpened plane and m freshly bought japanesey raspy file thing to form this handle fit....do you think I'm on the right track to attempt to fill the back? I reckon the front of the eye, if I moved the head across such that the back were filled, would be easily filled with basically a protruding wedge and just couple of small gaps, however i think the balance of the head would be awful at that point with the axis of the handle too far back by probably 3/8", maybe more. Striking accuracy would be dire. TBH, my accuracy isn't the bst anyway, but let's not handicap myself here. So plan is to plane the back of the handle flat, cut a lump of the bottom of the handle (its 36" so needs shortening), cut that in half and plane the cu surface flat and then shape to to fill the back of the eye. when good fit is achieved the wedge and the back filler piece will be inserted and glued with gorilla glue, an expanding wood glue. I think this way will be more work and harder to do....although i have managed to a good sharp edge o my cheap jack plane so maybe i can get a flat surface and get the filler piece to glue fimly on. however it feels like necesary work, or else the axe would be far too long on the nose. I am open to other ideas though, if anyone has one.

as you know I got hold of a pretty nice 4.5lb Hult Bruk head a while ago and have done nothing with it as its got an unusually large eye, the right length but about 1 and 3/8" wide! I have pondered if it were made with the long size of eye that exists in Europe and had been pounded on the poll and deformed but I find that unlikely as the eye shape looks uniform and right, just too big for any regular handle. So... I ordered 2 Pick axe handles in Ash. 2 as...well I was buying on line and they were cheap, 2 would allow some selection. both tight grained and no hearthwood, both straight enough although one slightly S-shaped (right one)

so one (left) loos really rather good! which balances out against the stick of firewood on the right.

a closer look

next I select ....the firewood on the right....as I think I may as well practice this hang on the rubbish handle

I drew a line to mark the depth of the head a the eye, i did allow for a small protrusion at the top, but not much. the perspective misrepresents that

Ah ha! i have over come the width issue, yay!

but introduced a length issue....hmm...that can be overcome more easily though.....can't it?

let's tale a look from another angle.... view through...nose of the eye is maybe 1/8" 'on' so once seated down on the handle which tapers heavily (as pick axes, like tomahawks, are friction fit) there shouldn't be a gap, but there won't be material to remove either. back has a good 1/8" gap against the top of th handle, so once seated down the a gap will be a good 1/4 inch.

So I drew another line or 3. Axis line sketched by eye, 'P' for 'Poor' handle and the material to remove.

and from another angle... yes looks about right at the nose.

Right so my question. before i take my freshly sharpened plane and m freshly bought japanesey raspy file thing to form this handle fit....do you think I'm on the right track to attempt to fill the back? I reckon the front of the eye, if I moved the head across such that the back were filled, would be easily filled with basically a protruding wedge and just couple of small gaps, however i think the balance of the head would be awful at that point with the axis of the handle too far back by probably 3/8", maybe more. Striking accuracy would be dire. TBH, my accuracy isn't the bst anyway, but let's not handicap myself here. So plan is to plane the back of the handle flat, cut a lump of the bottom of the handle (its 36" so needs shortening), cut that in half and plane the cu surface flat and then shape to to fill the back of the eye. when good fit is achieved the wedge and the back filler piece will be inserted and glued with gorilla glue, an expanding wood glue. I think this way will be more work and harder to do....although i have managed to a good sharp edge o my cheap jack plane so maybe i can get a flat surface and get the filler piece to glue fimly on. however it feels like necesary work, or else the axe would be far too long on the nose. I am open to other ideas though, if anyone has one.

As long as you securely fill the gaps you should be fine whether it is a wood, metal, composite or poured fiberglass.

wv311

ArboristSite Operative

Johann Wiebelhaus

My best guess at the moment .

From this

http://axessive.com/Axes/1-53-Lbs-SIGNED-RARE-VINTAGE-GERMAN-STEEL-AXE-HEAD-Johann-Wiebelhaus

My best guess at the moment .

From this

http://axessive.com/Axes/1-53-Lbs-SIGNED-RARE-VINTAGE-GERMAN-STEEL-AXE-HEAD-Johann-Wiebelhaus

wv311

ArboristSite Operative

Thank you sir !!Johann Wiebelhaus

My best guess at the moment .

From this

http://axessive.com/Axes/1-53-Lbs-SIGNED-RARE-VINTAGE-GERMAN-STEEL-AXE-HEAD-Johann-Wiebelhaus

Well guys I started this site when I built a fire pit. Next I had to have a MS261 saw for the firewood. Went looking for an old wood stove to put in the house cause now I have this saw and a passion for cutting wood. Now I have ended up here, with 2 Swedish axes. Don’t know how much more I need but this has turned into a way of life for me. Thanks for all the information and such.

Anyway, I reshaped the swell end of my GB SFA to more closely resemble the small hatchet handle. I like the feel of it better than the original shape. Now my question is about the thickness of the handle, I want to shave it down to give it a little flex but am not sure if it’s a good idea. Here’s what I have done so far.

Here you can see the original shape, it felt odd in my left hand.

Sent from my iPhone using Tapatalk

Anyway, I reshaped the swell end of my GB SFA to more closely resemble the small hatchet handle. I like the feel of it better than the original shape. Now my question is about the thickness of the handle, I want to shave it down to give it a little flex but am not sure if it’s a good idea. Here’s what I have done so far.

Here you can see the original shape, it felt odd in my left hand.

Sent from my iPhone using Tapatalk

Similar threads

- Sticky

- Replies

- 0

- Views

- 1K

- Replies

- 39

- Views

- 1K