I'm just in the part gathering and planning stage but I thought I would throw it out for those who would like to comment.

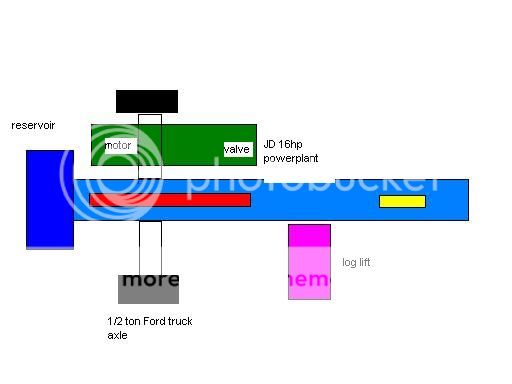

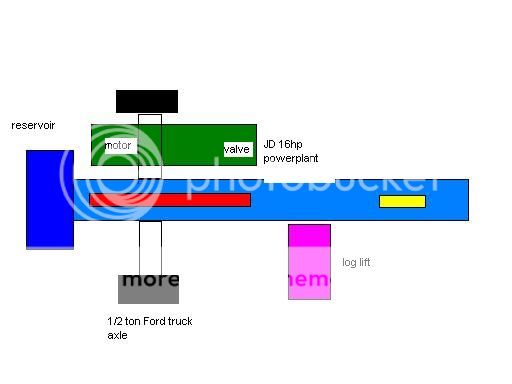

The layout. With such a heavy beam, 8ft length, I though I would put the oil tank on the back with framework to limit the heavy tongue weight. Motor is 16hp from a JD LT160 mower. I will mount the mower frame to the splitter to hold the gas tank/battery maybe even the seat for relaxing.

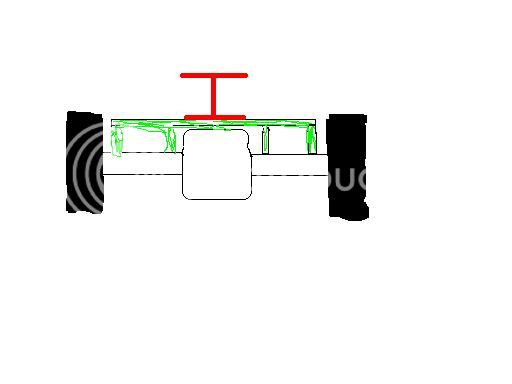

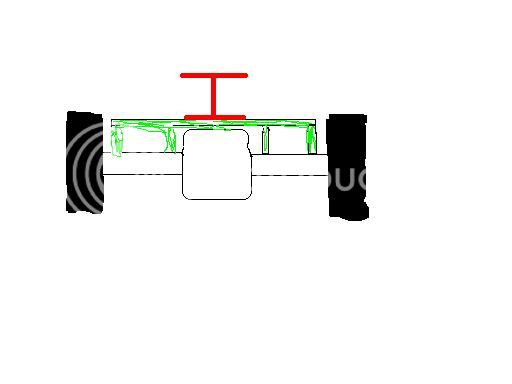

I'm using an F100 truck axle and I planned to make a frame work out of 5in channel that has the bottom cut out to fit around the 3in axle tube. The beam will be a W10x88, 5/8 web and flange just a little over 10in square. Overkill for sure but it is what I found.

Reservoir tank

The return is where the T fitting is and a tube inside actually runs it to the left side tank bottom. The return/suction ports are on the same side but the configuration is seperated inside the tank. The 2 bottom right fittings are the suction lines and have suction strainers inside the tank. I thought I would join the 2 ports with a Wye then to the pump. This way if one clogs I still have oil going to the pump. Or I can plug one take out the strainer then run the suction line to the pump. The port on the very left will be plugged.

22gpm Haldex pump

5x24x2 cylinder

4x30x2 that I bought prior

The old fashion hand crank came off my grain silo. I plan to use it with my log lift. It lifted the electric grain auger inside the silo with 3/8 cable so it is should work with larger rounds that weigh close to the auger.

Visited the local scrap yard and it had 1in thick scrap pieces (1ftx1ft and other sizes)that came from steel plates. New planter pieces were cut out from the plates at specialized planter manufacturer Bauer Manufacturing. These pieces should supply what I need for a wedge/pusher and cylinder mount. I think that is it for now. Will pick up the beam this week since the 36hr Xmas blitz is over. See ya

Brian

The layout. With such a heavy beam, 8ft length, I though I would put the oil tank on the back with framework to limit the heavy tongue weight. Motor is 16hp from a JD LT160 mower. I will mount the mower frame to the splitter to hold the gas tank/battery maybe even the seat for relaxing.

I'm using an F100 truck axle and I planned to make a frame work out of 5in channel that has the bottom cut out to fit around the 3in axle tube. The beam will be a W10x88, 5/8 web and flange just a little over 10in square. Overkill for sure but it is what I found.

Reservoir tank

The return is where the T fitting is and a tube inside actually runs it to the left side tank bottom. The return/suction ports are on the same side but the configuration is seperated inside the tank. The 2 bottom right fittings are the suction lines and have suction strainers inside the tank. I thought I would join the 2 ports with a Wye then to the pump. This way if one clogs I still have oil going to the pump. Or I can plug one take out the strainer then run the suction line to the pump. The port on the very left will be plugged.

22gpm Haldex pump

5x24x2 cylinder

4x30x2 that I bought prior

The old fashion hand crank came off my grain silo. I plan to use it with my log lift. It lifted the electric grain auger inside the silo with 3/8 cable so it is should work with larger rounds that weigh close to the auger.

Visited the local scrap yard and it had 1in thick scrap pieces (1ftx1ft and other sizes)that came from steel plates. New planter pieces were cut out from the plates at specialized planter manufacturer Bauer Manufacturing. These pieces should supply what I need for a wedge/pusher and cylinder mount. I think that is it for now. Will pick up the beam this week since the 36hr Xmas blitz is over. See ya

Brian