If you were having issues splitting ash I would suggest there is a problem with your current setup. May be a worn out pump, cylinder blow by or your wedge is too aggressive. Do you have access to a pressure gauge or is there one on there? Most splitters have no issue with elm as it is just stringy and makes it hard for manual wedging or doing it by hand. I'm running a 5 inch and it can split most everything you throw at it. With a 7, even at a lower idle, you are going to have to be careful. Totally agree with muddstopper, your base plate is going to bend quickly.

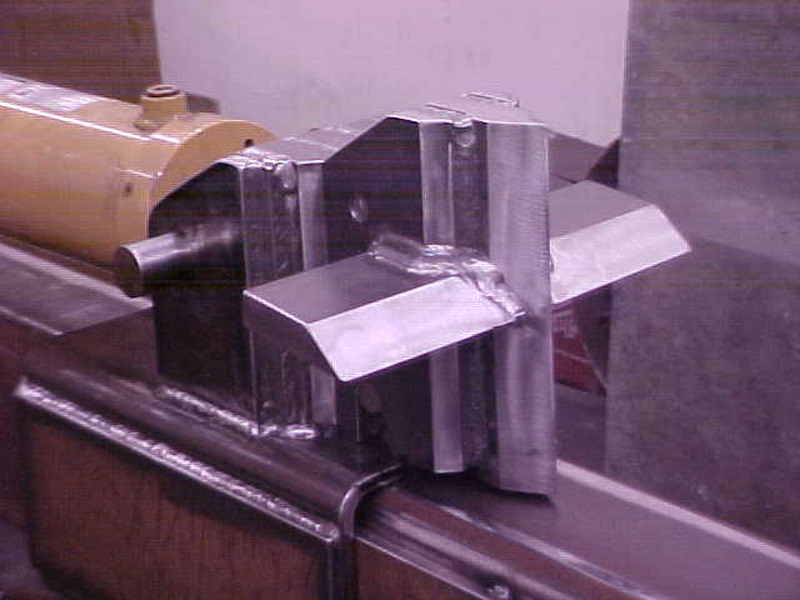

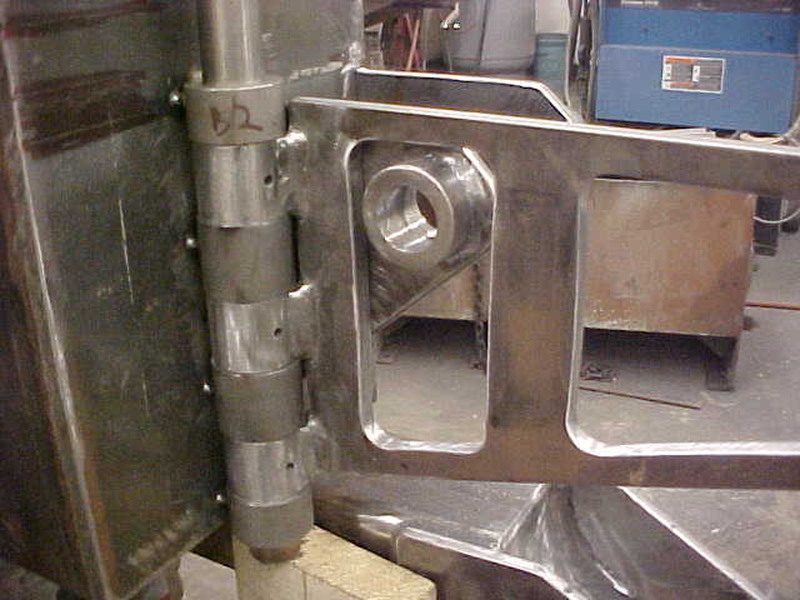

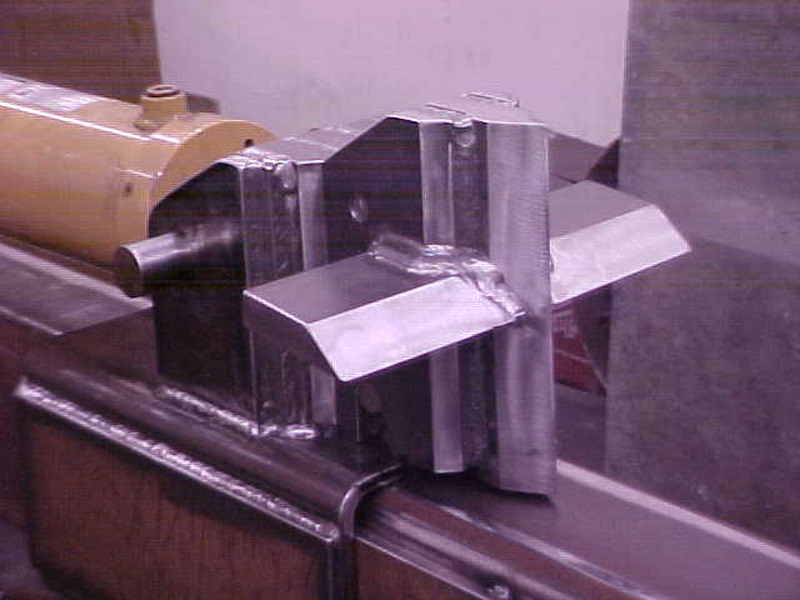

I have a wedge on the ram but mine is horizontal only. I never liked vertical and get around that with a lift boom for the big stuff. I made a quick release system for my wedges that requires no tool and is just a single pin and drop pin to hold it.

Lower pin is fixed and drops over. Rock back and slide pin in and a chopped bolt is dropped in from the top to lock in place.

Make sure if you make a 4 way to not have the contact surface all at once on the cross. Let the upright start to split then the secondary horizontal. have it lift up as shown above to avoid pinching. Honestly, with what you have now I wouldn't recommend doing it as it'll just bend your base faster. I was going to do a 6 inch on mine and I have the strength there to handle it. I decided not to as the speed was more important than the 2 times in 1000 I might need a 6 inch bore and I'm running a 28 gpm pump. I know you have the 7" allready but I don't think you'll be happy in the long run. Once again, if you do decide to move forward with it, be careful. A 7 inch can pop those bolts and they will fly like missiles. I split for a while with a guy how had a 8" cylinder with 12, 5/8" grade 8 bolts on his slide. He ended up putting a guard over the bolts after he got hit with one. He ran that thing off an excavator.