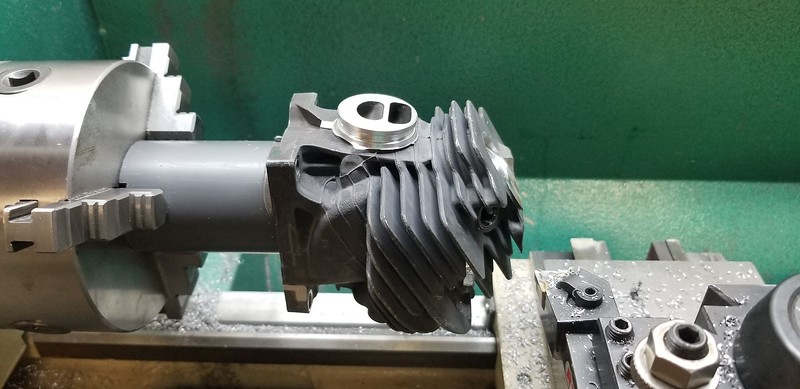

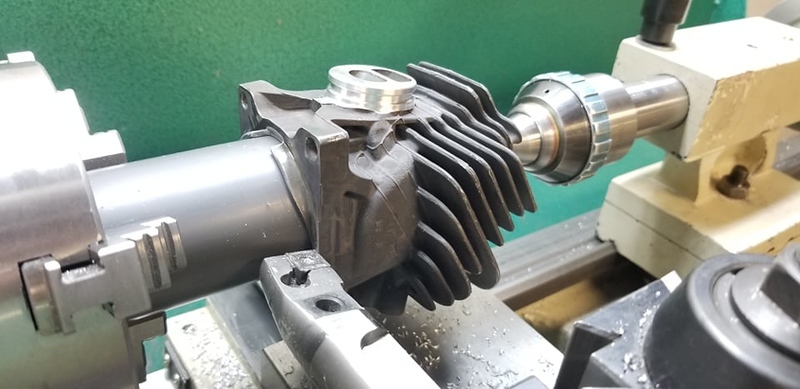

This cylinder did not have a flat spot on the top for my live center, so I put it on a tight PVC mandrel and turned it down until I had a flat spot in the center. I then took .007" off the base, resulting in a squish of .018".

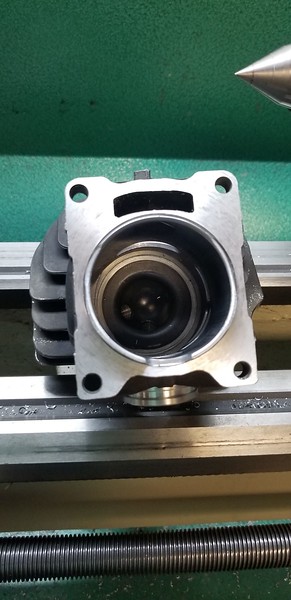

Here's the porting completed. Yes, I gutted the strato.

In my experience, nothing else comes close to making the power in these saws like the 241 and 261 do with the stratos gutted. The saw is back together, MTronic reset, and it runs fantastic with lighting throttle response. Unfortunately, it's after 10:00, raining, and there is no way I can make a video of it cutting. Sorry, I'd love to run it as well!

The bottom ring end pin is off to the side of the exhaust port, so I only widened it in the other direction. That's why the bottom of the port looks a little off.