I put on the new top end. Passes vacuum and pressure test. It seems to run smoother. Still a little laggy off idle.

It is still topping out at about 10.5k rpm with 3T out on the high screw. This is with no bar and chain.

I adjust low speed and when turning in reading the tach for peak rpm. It peaks at about 1/2T and then stays constant until the screw is all the way in. So I went back to where it first peaks, then out 3/4T per the manual.

It will still not start with decompression on. It "runs" with the button still down then dies if I touch the throttle. I cleaned the button when I moved it to the new cyl and it actuates well and has a nice click to it.

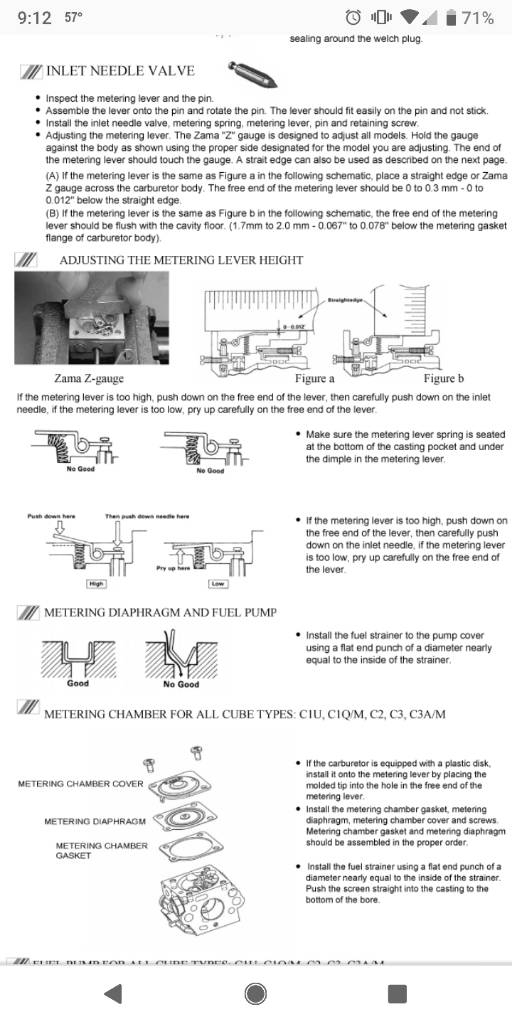

Using pre mixed 40:1 in a can to rule out all variables. It is still pretty oily around the exhaust so I am going to remove the carb and move the metering lever down a tad and try that per some earlier comments that even at flush it does not run well.

The ring gap for new OEM P&C 575257406 was .011" at the base.

Now that it's been run in a few minutes I will check the compression when cold.

Maybe I need to try cutting with it?

The "new" piston I ran in the old cylinder looks like it was already getting beat up per the shiny area on the exhaust side (photo below). So I'm glad to go with a new top end.