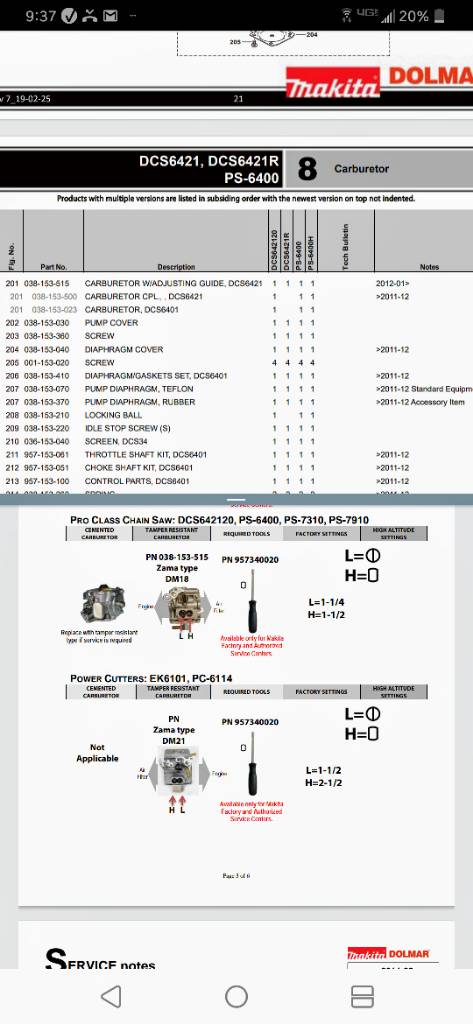

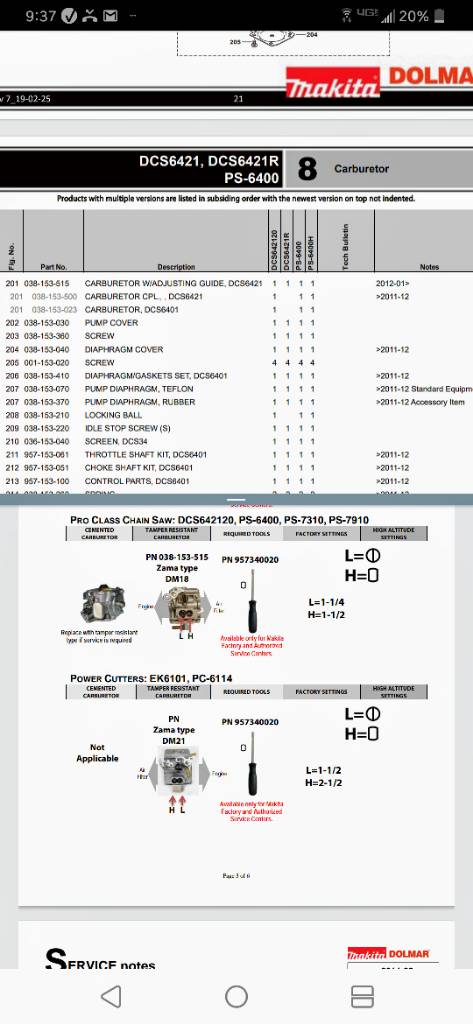

I just purchased a new makita 6421. Turned the H out 1/4 turn for break in. Didnt think to check where they where when I got from home depo as it was slightly 4 stroking in the wood and I figure thats good enough for break in. Now ive got a few tanks in it and and went to retune. I noticed they had the H 2 full turns out. And L 1 1\2 out. I looked up factory setting and found in pic below. Correct me if im wrong but could I theoriticly just tune to those settings in the pic? If I found the right carb that is. Then reset idle to 2500 Rpm? My ear is not so good as im new and only have a junk tach I dont trust and,dedinetly dont trust my ear yet. Many of you have already told me this and sent me stuff but I'm just not trusting myself i guess. I looked up hours and hours of vidios on this. Maybe just thinking way too much into it. Really dont want to blow her up. Any info is appreciated.