AZLOGGER

ArboristSite Guru

- Joined

- Jan 20, 2006

- Messages

- 558

- Reaction score

- 125

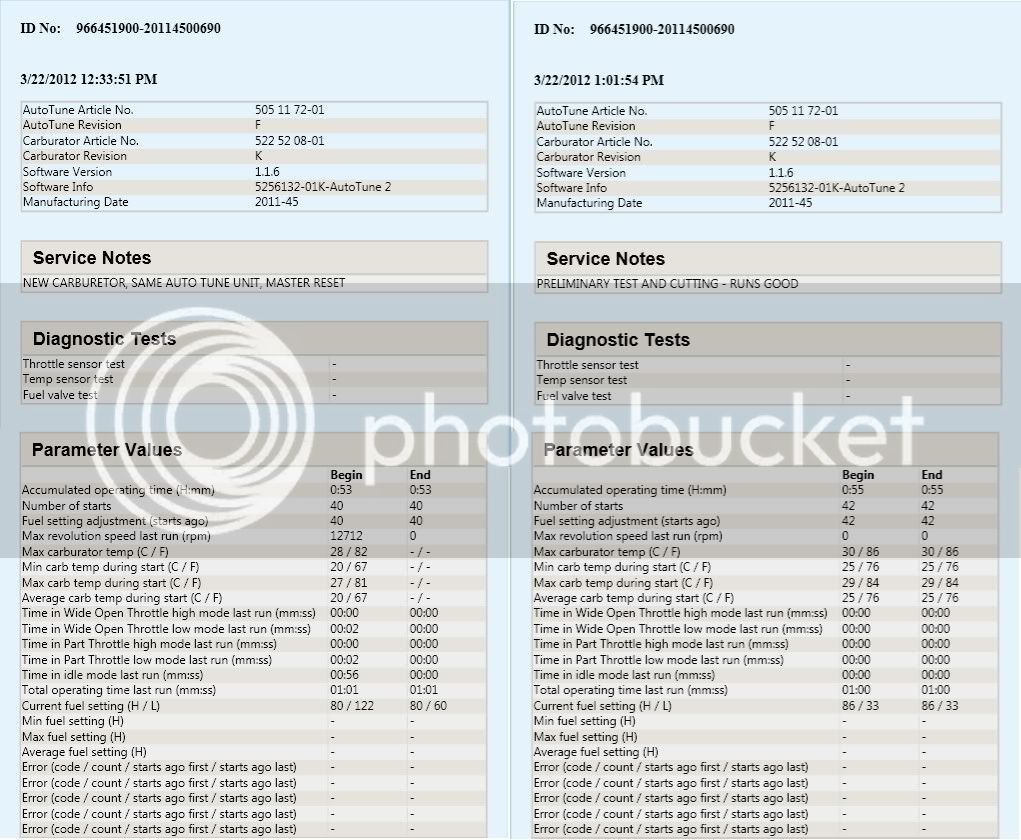

There is no programming or software involved with the 570/576AT saws. You can not plug them into a computer.

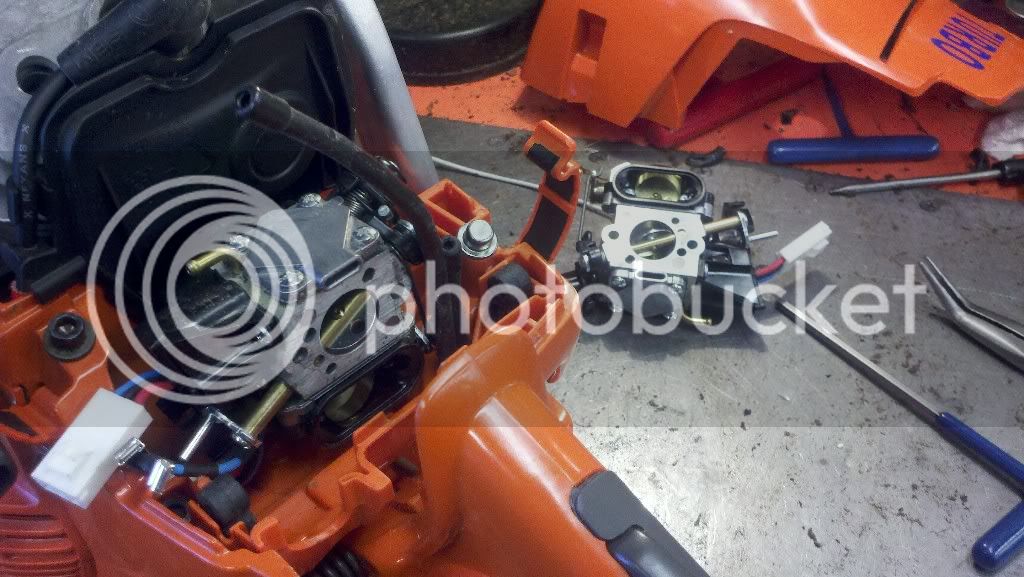

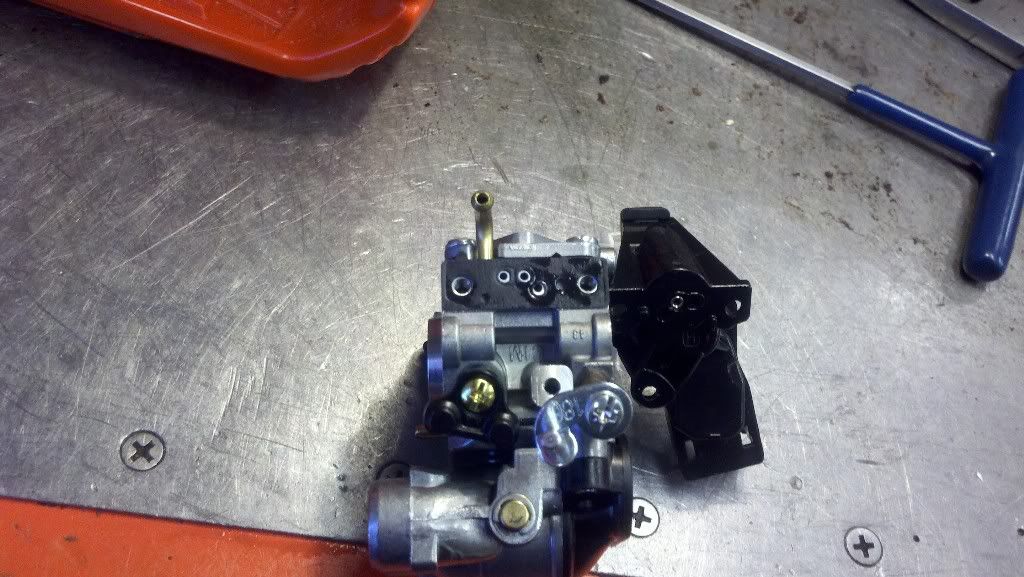

From the Husqvarna Service School, this is very correct, the 555 & 562's have a totally different AT system. I was under the impression that the only time you needed to reprogram the saw, was when you change the carb. I don't think I was asleep:msp_sleep: during that part of the session, but could of been! Our instructor (Scott Willis) was very straight forward, kind of like the old HS days.