Detonation and Preignition

By:

WDRacing

To me there isn’t anything cooler then watching the needle on an analog boost gauge race towards a number that would make most people flinch or cringe… as if they’re expecting to hear some sort of gunshot followed by metal on metal warfare. Not me. I’m a boost addict right down to the core of my soul. Too much being almost enough in most cases. It’s this same desire that’s helped me to send my fair share of motors to the boneyard ahead of their time. Well you can only screw around for so long before you realize that doing it the right way insures a lot more time spent behind the wheel and less in the garage. You’re not going to successfully run huge numbers of boost unless your tune is on the money. In my humble DIYer opinion, there is one thing more important then any other aspect of tuning, and that’s understanding and controlling detonation.

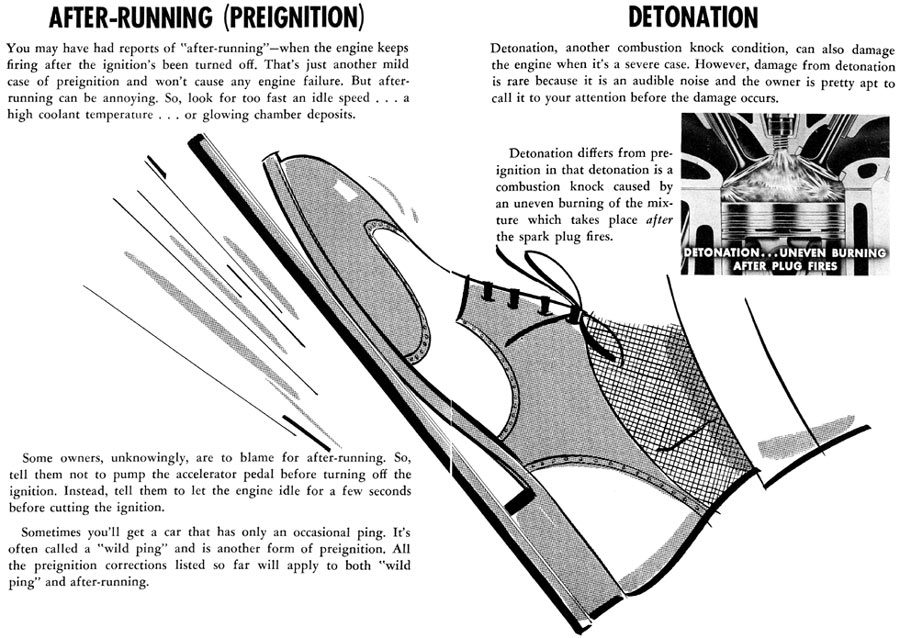

Let’s roll through the normal combustion process first. I don’t want to use a bunch of technical speak here and muck it all up trying to use big words, so I’m going keep it as base as possible. Normal combustion is simple. The air and fuel mixture (AFR) is being compressed by the piston as it travels up the cylinder. When the piston reaches a predetermined point (we’ll use 20* degrees before top dead center, or BTDC for our example), the spark plug fires and starts the combustion process, originating at the plug tip. The burn should be steady and even as it spreads out from the plug and moves across the chamber, like throwing a rock into a pond. At the end of the combustion process, all of the air fuel mixture has been burned and the piston is traveling back down the cylinder. There is no “explosion” – just an even and controlled ignition. Notice I said even and controlled, that’s the key to the entire process.

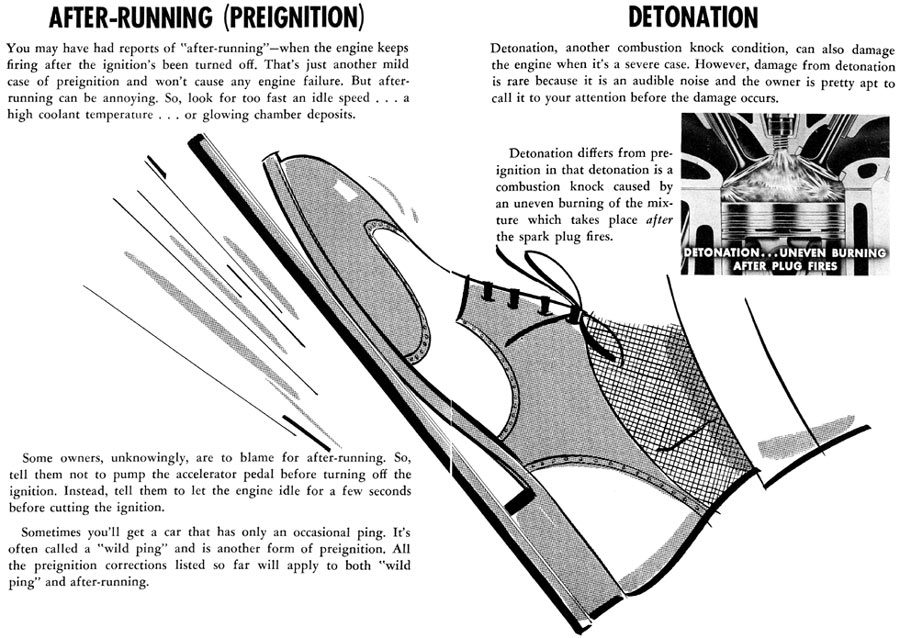

It’s hard to define detonation and not pre-ignition because the two are often confused and or misunderstood. Detonation and pre-ignition are two distinctly different types of combustion. Detonation is the AFR mix igniting by itself due to heat and pressure. Detonation is what occurs AFTER the spark plug has fired. Everything that happens before the spark plug fires is considered pre-ignition. Simple, right? Maybe, maybe not. How do you know which one you’re suffering from and what causes what?

Pre-ignition represents the worst possible thing that can happen during the combustion process. Detonation is pretty common and motors can run for 100’s of thousands of miles while suffering from light to moderate knock – Especially today’s newer cars with intelligent knock monitoring. However, these aren’t high performance engines.

Pre-ignition is what happens when you have a hot spot inside the combustion chamber. A hotspot is something or some area that gets hotter then anywhere else. The usual suspects are the plug ground strap, the plug tip itself, or even a bit of carbon on the exhaust valve or the piston head. Basically anything that can act like a “glow plug” inside the combustion chamber can cause pre-ignition.

What we have during a pre-ignition event is the AFR mix entering the chamber as the piston is reaching the bottom of its stroke and returning to the top. When the piston is at the bottom of its stroke, the pressure AND temperature of the AFR mix is the lowest. As the piston travels up the cylinder the temperature and pressure increase greatly, making the mix harder to ignite. Sometimes the pressure is so great the spark event isn’t strong enough to ignite the AFR all the way (or at all) in some cases. This is the reason for aftermarket ignition amplifiers. I’m only explaining this now so you understand that there is a substantial difference in temperature and pressure between the top and bottom of the piston stroke. At the bottom of the stroke the AFR mix is at the point where it ignites the easiest. This is where a hot spot, if it exists, can ignite the AFR mix causing pre-ignition. The result is the entire AFR mix lighting off at once as the piston is moving up the cylinder. You’re not going to stop the mechanical rotation of the crankshaft so the poor piston is left trying to compress an explosion. The heat generated will melt the crown of a forged aluminum piston in a fraction of a second. Total engine failure is always the end result of pre-ignition. Unfortunately, you often don’t get a chance to troubleshoot pre-ignition. On the rare occasion that you are, some of the signs that you’re suffering from pre-ignition are worn and eroded spark plugs – Sometimes the ceramic will be cracked or missing.

To stop pre-ignition ahead of time you need to eliminate hotspots and keep the motor running at normal operating temps. A motor that runs hot is making every single vehicle system work harder. The correct heat range spark plug is a must. An incorrect heat range plug can induce pre-ignition all by itself. Hotter plugs are better for cold starting and idle etc, but bad for a high output motor. Forced induction motors should always run 2 or 3 heat ranges colder then a NA motor. If you’re motor is run under a load for an extended period of time you’re going to need to take extra steps to avoid pre-ignition. Some manufacturers use piston oil squirters, small jets that spray oil onto the bottoms of the pistons. This cooling of the AFR mix inside the combustion chamber is called quenching. The cool sides of the cylinder and piston head “quench” the AFR mix as it ignites, helping to control the flame front as it spreads out across the chamber. Regardless of steps taken, all efforts to avoid pre-ignition MUST be considered throughout the build and during the tuning process.

Like I mentioned earlier, detonation is an event that happens after the plug has fired. It’s caused by too much heat and pressure inside the combustion chamber. The high heat and pressure become great enough to light off the remaining AFR mix all by itself. The result is multiple flame fronts inside the combustion chamber. When this occurs, you get a sharp spike in cylinder pressure. If you were data logging cylinder pressure you would see a steady rise in pressure as normal combustion occurs, followed by a sharp but brief spike caused by the detonation. The sound you hear, referred to as knock, is the engine itself and the rotating assembly absorbing the shock, not the actual combustion inside chamber. The frequency of detonation is close to 6400 Hz, in almost all engines – with little or no difference between aluminum and iron blocks. The knock sensor picks up vibrations at this frequency and tells the ECU to pull timing and / or add fuel. Severe detonation can’t be compensated for by the factory ECU, although there are some aftermarket systems that will go as far as to shut down the motor under severe knock. Moderate levels of knock will cause bearing wear, something often misdiagnosed as normal wear or some sort of lubrication issue. Bearing wear can turn into rod knock real quick. Lock up a bearing and you throw a rod through the block in most cases.

Forced induction motors are very susceptible to detonation because of the high temperature and cylinder pressures created under boost. The knock count, or type of knock can go from light to severe very quickly under load. It’s this situation that causes broken rings lands and engine wear. An engine prone to detonation will also run hot, which compounds the problem because an engine that runs hot usually suffers from more knock. The scenario continues to snowball until the knock becomes destructive.

Octane ratio is a fuel’s ability to resist auto ignition. That means when it’s heated to a certain point, it will simply ignite by itself. For instance most pumps offer 87, 89 and 91 octane gasoline. The smart people of the world have already written everything on octane ratio, so I’m not going to explain the formula. You can take my word for it when I say, 91 octane pump gas has a higher resistance to knock then 87 octane. A motor that runs fine on 87 octane might suffer from mild knock on a really hot day – This is an example of how sensitive engines can be to fuel octane.

Once any particular fuel reaches its knock threshold it will spontaneously ignite. Again, the severity of detonation differs greatly, but a performance engine runs very close to the knock limit all the time – because that is where the power is! Things like heat soak also decrease the amount of time you can stay under load, so if you’re racing, don’t assume that just because it was good on the last pass that it’ll be good for another pass without a cool-down period. There is a fine line where ignition timing, compression and boost pressure all work in harmony to burn the AFR mix.