pursang

ArboristSite Lurker

- Joined

- May 13, 2014

- Messages

- 30

- Reaction score

- 18

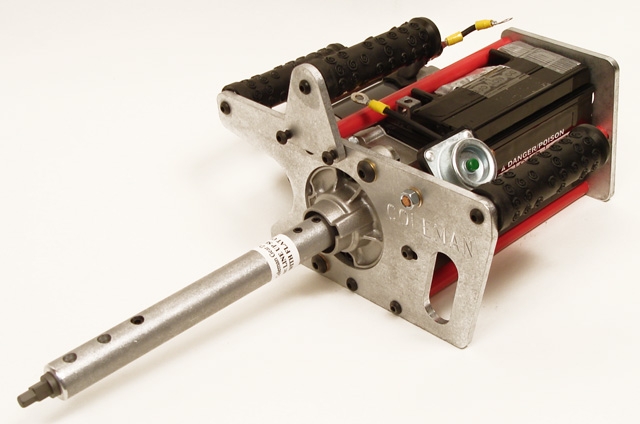

I'm looking for ideas to build an easier way of starting chainsaws, particularly larger displacement saws or one's that are just cranky to get going, I've seen a bunch of methods and decided on using this 12 volt starter mounted to the receiver hitch on the front or rear bumper. if anyone has any ideas, advice or if you've made your own alternate starting method please post up some pics and info.

The starter will drive the flywheel the same way the pull starter does using the pawl slots.

This Toyota starter should be strong enough for starting any chainsaw.

The starter will drive the flywheel the same way the pull starter does using the pawl slots.

This Toyota starter should be strong enough for starting any chainsaw.