That's what I heard. I've yet to confirm that, though.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Alternative Starting Methods?

- Thread starter pursang

- Start date

Help Support Arborist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

I have replaced four ruined Stihl ElastoStart assemblies for four loggers running MS 660 and MS 661 saws. They all drop start them. Seems like cause and effect to me, but I could be wrong. Two of them never used the decomp valve, even with a cold engine.

- Joined

- Jan 11, 2014

- Messages

- 3,378

- Reaction score

- 3,996

Decomps were designed to save on starter wear, from what I have read, not to make a saw easier to start.I have replaced four ruined Stihl ElastoStart assemblies for four loggers running MS 660 and MS 661 saws. They all drop start them. Seems like cause and effect to me, but I could be wrong. Two of them never used the decomp valve, even with a cold engine.

But after how many starts?I have replaced four ruined Stihl ElastoStart assemblies for four loggers running MS 660 and MS 661 saws. They all drop start them. Seems like cause and effect to me, but I could be wrong. Two of them never used the decomp valve, even with a cold engine.

I have limited experience, but In a lot of heavy logging where I am coordinating with others, the saw gets shut off after every tree to shout & listen.

I try to be easy on my ****, but most don't care.

"It's company tools, I'm not paying for it"

Also, when the boss is not around 90% of the time I watch guys start the saw with the bar tip on the ground, saw vertical standing up on the bar, loosly holding the rear handle,and often at stupid angles to the hole the rope exits.

The saw flips around wildly this way, and I have watched a couple times when this kicks the chain off the rail, or in one case, rips out a bar stud.

Not the smartest, but it's what actually happens.

pursang

ArboristSite Lurker

- Joined

- May 13, 2014

- Messages

- 30

- Reaction score

- 18

I've never been to a chiropractor but I've heard bad things about them, an injury is why I'm exploring this, this set up would rarely be used and like my $ 90.00 Snap On ball joint press when you need one it does the job, it's invaluable.I badly bruised ribs and boy did that make starting a saw tough.

Worst part is the chiropractor did it. Went in to get my back sorted out, could barely stand and it had been a week or so.

Fixed that, but made my chest hurt. Next day looked like I'd been kicked in the chest by a moose.

I was running a 288 at the time so it took a good pull to fire it up.

Wasn't too bad once I figured a position that didn't flex my rib much. Coughing or sneezing really sucked!

pursang

ArboristSite Lurker

- Joined

- May 13, 2014

- Messages

- 30

- Reaction score

- 18

Yeah, that's a great idea man, I'll get right on that.This has to be a joke, if not, I’d look into handheld starters for large RC airplane engines and adapt the flywheel for one of those.

pursang

ArboristSite Lurker

- Joined

- May 13, 2014

- Messages

- 30

- Reaction score

- 18

Yeah, at the moment I'm broken, but unless someone wants to come dig the hole and throw me in I'll just keep going.If a couple pulls/drops doesnt get some action...its broken

Sent from my LM-G820 using Tapatalk

pursang

ArboristSite Lurker

- Joined

- May 13, 2014

- Messages

- 30

- Reaction score

- 18

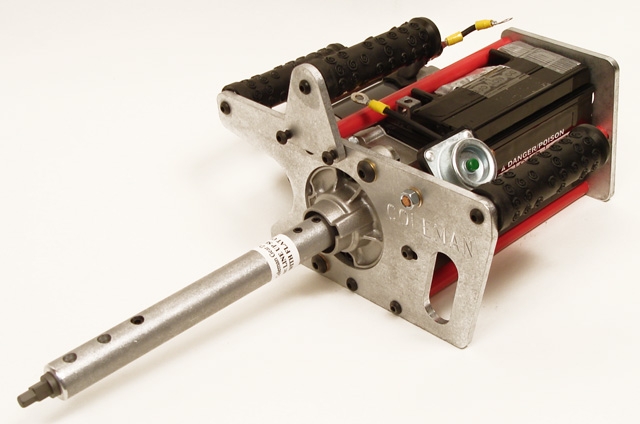

I've never liked 125s or those nasty 80s, always 250 and open class for me, you might be right about the overkill but it's only a four banger starter so I'll determine if it's too much when I get it set up, the starter will be mounted to a receiver hitch with a button you push with your foot. the attachment will be a nylon gear in the shape of the pawl dogs on the flywheel.Wow - a car starter seems like immense overkill depending on how you power it.... you could fracture crank bits.

We used to start 2-stroke GP racebikes with cordless drills (although for 250's it was almost mandatory to use a corded drill, but 125's could use a cordless - however this was before some of these high amp high torque cordless drills like there are today), using a special socket with a one-way bearing/clutch so the drill didn't break your wrist...

It had a reverse thread nut that spun onto the stator. I'm sure something similar could be welded/machined onto a chainsaw flywheel.

Here's the one I had:

https://www.accu-products.com/accu-products-specialties/starter-tool/prod_3018.html

pursang

ArboristSite Lurker

- Joined

- May 13, 2014

- Messages

- 30

- Reaction score

- 18

For now I'm going to have the starter stationary while holding the chainsaw, I'm definitely using a nylon gear on the flywheel.That seems an odd choice when you can use a ready built Kart starter, but maybe it's cheaper? Kart starters typically utilize a large hex, and its reversed for engines (female head bolt is on the engine).

You can buy purpose made slip clutch sockets (I am sure they have a proper name) or use the nylon drive cogs that allow slip.

Myself, If I do not have the right size slip socket on my drill, I will use a heavier push from an old air impact. The impact sockets do not enjoy disengaging but the impact itself can be over driven without damaging it.

Most of the time, I have only had to use this method with cranky points engines or ones where I have no reference for initial carb settings (and 1-2 isnt working).

Musing on it, I do not know if I'd be using a starting device for a chainsaw off the bench. In racing you have multiple people required to start an engine for saftey, each doing only one task.

pursang

ArboristSite Lurker

- Joined

- May 13, 2014

- Messages

- 30

- Reaction score

- 18

I've seen so many guys drop start their chainsaws I just respect they've been doing it for years and have made it safe.Agree, lot of people drop start, not safe.

pursang

ArboristSite Lurker

- Joined

- May 13, 2014

- Messages

- 30

- Reaction score

- 18

I'm alright I just have something that hurts when pull starting, worked my ass off all my life I'm not stopping.This is probably a jerk comment...but I don't see how a person could be physically capable of safely running a saw without being to pull start it.

An automotive starter does not seem like a good idea... the flywheel would get tore up pretty quick.

pursang

ArboristSite Lurker

- Joined

- May 13, 2014

- Messages

- 30

- Reaction score

- 18

That's quite a contraption, I only wish they made it seven feet long with a diesel engine.

pursang

ArboristSite Lurker

- Joined

- May 13, 2014

- Messages

- 30

- Reaction score

- 18

Originally I was looking for a 12volt Mini Brute, I found one on ebay but the postage must've been horrendous cause the guy wouldn't even respond. I'd still like to own one but not I love my Stihl.Ever see a hydraulic or marine chainsaw? No pull-starts on those.

However I do see where you are going and partially agree. Not really a fan of the easy-start for the same reason.

pursang

ArboristSite Lurker

- Joined

- May 13, 2014

- Messages

- 30

- Reaction score

- 18

That's a good idea, or something like the way an auger is driven on a snowblower.Thinking on it, if you really want to build a mechanical chainsaw starter, the best option for a chainsaw would be a friction-drum type starter.

The easiest way to build it would be to take a bench grinder, use an old grinding wheel or make a drum, and glue/affix some rubber belt to it.

You would then simply turn on the bench grinder at the proper speed (if it is variable) then, with both hands on the saw, bring the flywheel down to contact the drum.

I belive that is probably the safest option for a one-person setup.

pursang

ArboristSite Lurker

- Joined

- May 13, 2014

- Messages

- 30

- Reaction score

- 18

I'm new to chainsaws but I'm a seasoned Motocrosser, agression is a good thing when starting either one, sometimes it hurts !I always drop start, I managed to **** up both my back, and a few saws by putting them on the ground to start as they tell you too when I was a teen.

broke the rear handle clean off a 038 once... never had a single issue drop starting a saw.

plus, drop starting puts me in a good position to react if something goes wrong, I can't move or react fast when bent over.

also, if it kicks back while drop starting, am less likely to fall onto the saw, and more likely to have it just pop out of my hand, i know this from experience.

I fell onto my 372 once when it popped & I was standing on snow with my foot in the rear handle. thankfully it wasn't running yet...

pursang

ArboristSite Lurker

- Joined

- May 13, 2014

- Messages

- 30

- Reaction score

- 18

pursang

ArboristSite Lurker

- Joined

- May 13, 2014

- Messages

- 30

- Reaction score

- 18

I have a couple plug in saws I use them around the house mostly to keep the noise down and to save my MS260. eventually the price of cordless stuff might come down and I can use the smaller crowbar to get into my wallet.Get a battery powered saw, if you are close to an outlet get an electric saw. I know more than a few folks that have serious medical issues that have made the switch to some sort of electric saw, it works for them. Yeah, they cut slower, then again these folks move slower.

If you cannot pull it over, then it is not for you.

pursang

ArboristSite Lurker

- Joined

- May 13, 2014

- Messages

- 30

- Reaction score

- 18

No I plan on starting the saw in the usual way it's only if I'm having trouble and in the middle of a job I can set this thing set up in a few minutes and get to work, I have a thing for fabrication and building tools so it's in my boathouse.Problem with having a seperate electric starter is having to return to the electric starter every time you want to start the saw.

The whole point of a petrol chainsaw is it operates independent of another power source.

Might be a better idea to sell the petrol saw and use the money to buy a battery-pack saw.

On the subject of drop starting saws -

Been drop starting saws since 14yo ( Back when a 120cc saw without chain brake or decompression was normal) and now nearly 60 = never had a worry.

Ground starting a saw is harder on the back.

To ground start a saw safely you need flat clear ground - not much of that around in rocky scrub and hill country.

Try ground starting a saw from 60 foot up a gum-tree ?

Ground start a saw knee deep in branches and offcuts ?

Drop starting gives a faster start rope pull, which gives easier starting.

TO each their own - but most people who say drop starting is dangerous have never learned how to properly drop start a saw.

pursang

ArboristSite Lurker

- Joined

- May 13, 2014

- Messages

- 30

- Reaction score

- 18

Bringing an engine up on compression has always worked for me, unless your injured then it just hurts for awhile.Starting big saws, especially with high compression just requires technique. I'm kinda of the mind that if you cannot start it, barring temporary injury, you ought not to run it .Madsens has a smaller one armed tech that started my ported 880 with ease. Now drop starting 101b Macs is tough I'll grant you. However, drop starting those big Macs is the way they start easier. When you start these saws you need to be committed in the pull. I drop start my 125 with 50" bar without issue. Longer bars, like 60" + should be placed on top of wood or over a log. BTW, mosf of these saws start easier when there is no decomp. Again, learn the technique. A stock 880 with decomp should be a pussycat to start period. An automotive starter is pretty ridiculous as is leaving the flywheel cover off.

pursang

ArboristSite Lurker

- Joined

- May 13, 2014

- Messages

- 30

- Reaction score

- 18

I hear what your saying, thanks for the advice.I normally prop the rear handle sort of between my legs, under my right knee. Hold front handle with left hand, pull starter handle with right.

That has worked fine for most saws I've run.

The bigger ones being 2100, 288, 880, 660.

If the saw has a long bar where it's very nose heavy, rest end on a stump, log, etc, hold rear handle with left hand, right hand to start.

Falling over while foot is in the rear handle? You need to be leaning back using the knee that's on the ground for balance and support.

Had a friend laugh at me for starting my saw "by the book"... "real men" drop start saws.

I've had to leave a saw for my buddy to start if my back is acting up. Fine to pull 2-3 times on my saws, but customer saws at times can give a person a real workout.

Would be handy to have electric start of some sort for that.

Similar threads

- Replies

- 8

- Views

- 889

- Replies

- 6

- Views

- 4K

- Replies

- 0

- Views

- 962

Latest posts

-

-

-

-

Please recommend a small chipper- Boxer x7 vs Vermeer bc700xl or....

- Latest: Crftrapper535

-

-