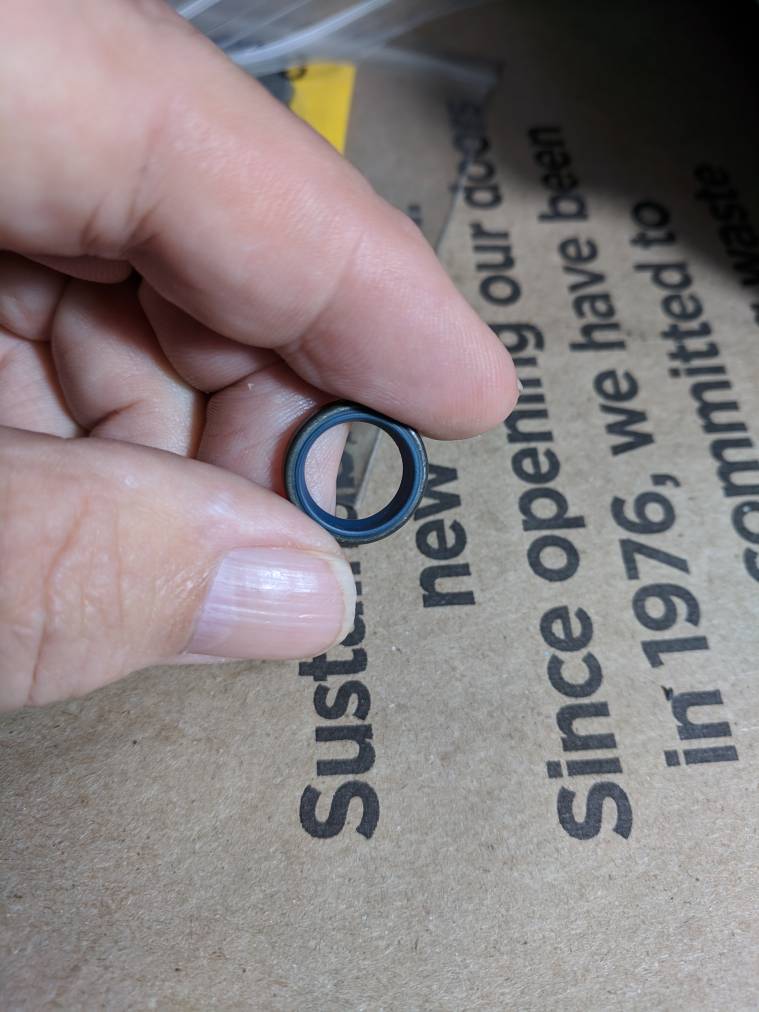

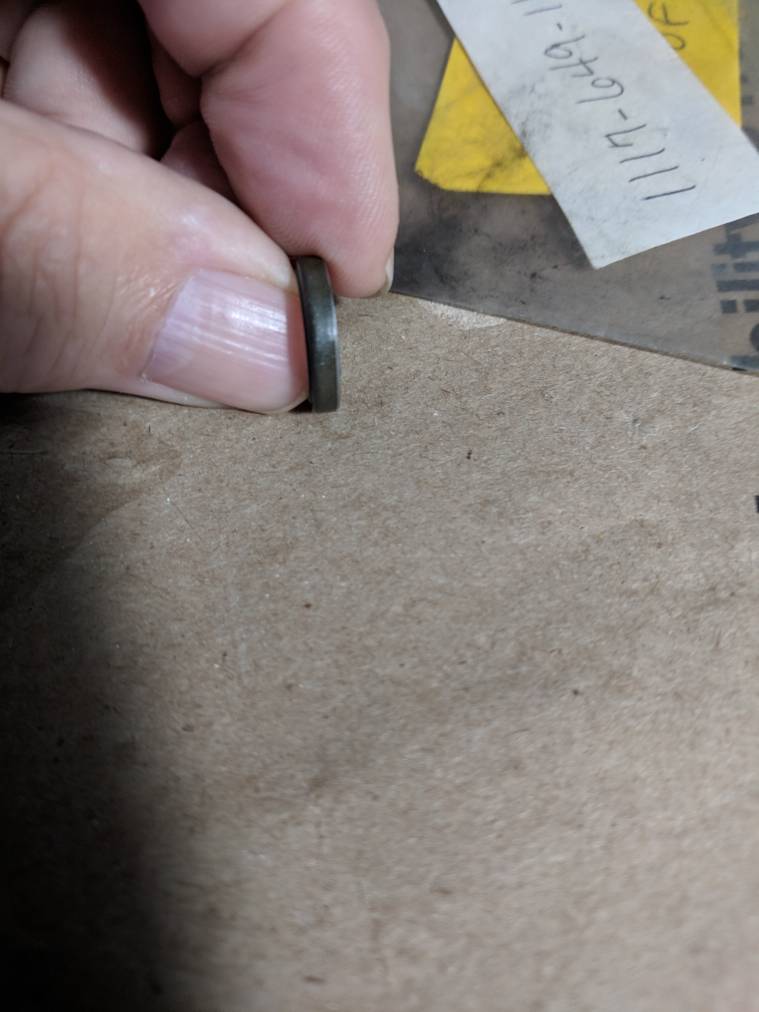

Are you asking about the orange saw? I doubt anyone has purchased that one.Is anyone else having issues with the oil fill port & cap?

Took quite a while with a Swiss pattern file and a cap from my dealer to get it to work correctly. [emoji3525]

What was the problem exactly?

chainsaw kits and packing lists

http://thechainsawkitguy.com

http://YouTube.com/c/the1chainsawguy