weedkilla

Ain't no guru of nuthin'

Obviously I am talking about using a dyno as a development and diagnostic tool. That's not what chad is doing here. He's giving a saw a run, not doing development work for someone else.

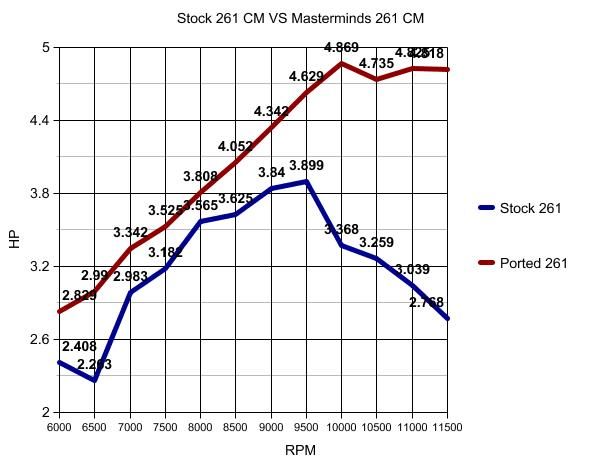

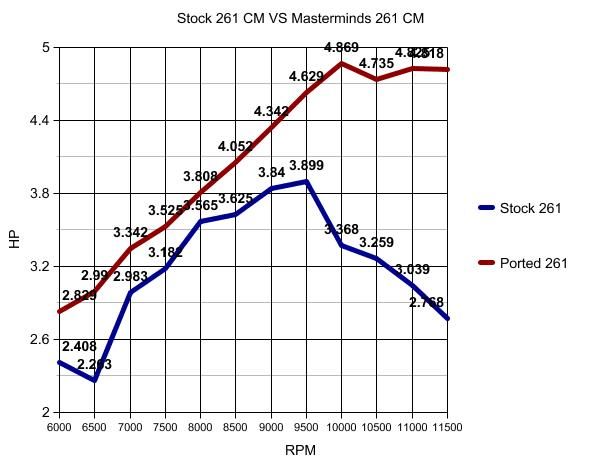

Well..... After we've gone "holy crap that's an amazing gain", there isn't much else to talk about. I've found dyno time addictive in the past, there is always one more thing to try. Perhaps we should have mentioned the bigger dip in the stock power curve.You guys over analyze this stuff......just saying.

Do u think direct injection or efi on saws will be programmable?I fail to see how a tenth of a HP dip is an issue. Why major on the minors, the miniscule? It's not like the thing has a programmable ECM where you can just tune it out.

I doubt the API or an interface will ever be made available.Do u think direct injection or efi on saws will be programmable?

Well..... After we've gone "holy crap that's an amazing gain", there isn't much else to talk about. I've found dyno time addictive in the past, there is always one more thing to try. Perhaps we should have mentioned the bigger dip in the stock power curve.

When the discussion becomes too technical......the average member is gone.

But you are right.....there ain't much to say.

I'm pretty happy with the way our 261s turn out. I had someone send me a PM asking about how I knew I was done tweaking this saw. How I figured that out sorta. I have no secrets.....if you want to know what timing numbers, etc I use in a certain saw.....just ask. Lots of hard work is the answer.....

My method consists of going two degrees at a time, on a different port at a time, with no other changes, and then testing in wood. I video the cuts and time them to compare.

When I was testing this model I regularly had three or four of them here at a time. I would sometimes do all of them just a little different.....then test in popular cants.

What I post on the threads, and on YouTube is just a very small part of the testing I've done.

That's the reason there are times when I get even further behind. No way I can produce 5 - 6 saws a week and spend days testing a certain model. The testing is the most important thing we do though......without that, our saws would just be so-so....

just remember guys, randy's all booked up til mid octoberthat's one heck of an increase.

I'm beat but got the testing done tonight. My rpm sensor wouldn't read past 11500 rpms. I'd still like to test up to 13000 if I can get a shaft rpm sensor that will read that high.

Wow Randy this is a hot 261cm.

I'm beat but got the testing done tonight. My rpm sensor wouldn't read past 11500 rpms. I'd still like to test up to 13000 if I can get a shaft rpm sensor that will read that high.

Wow Randy this is a hot 261cm.

Enter your email address to join: