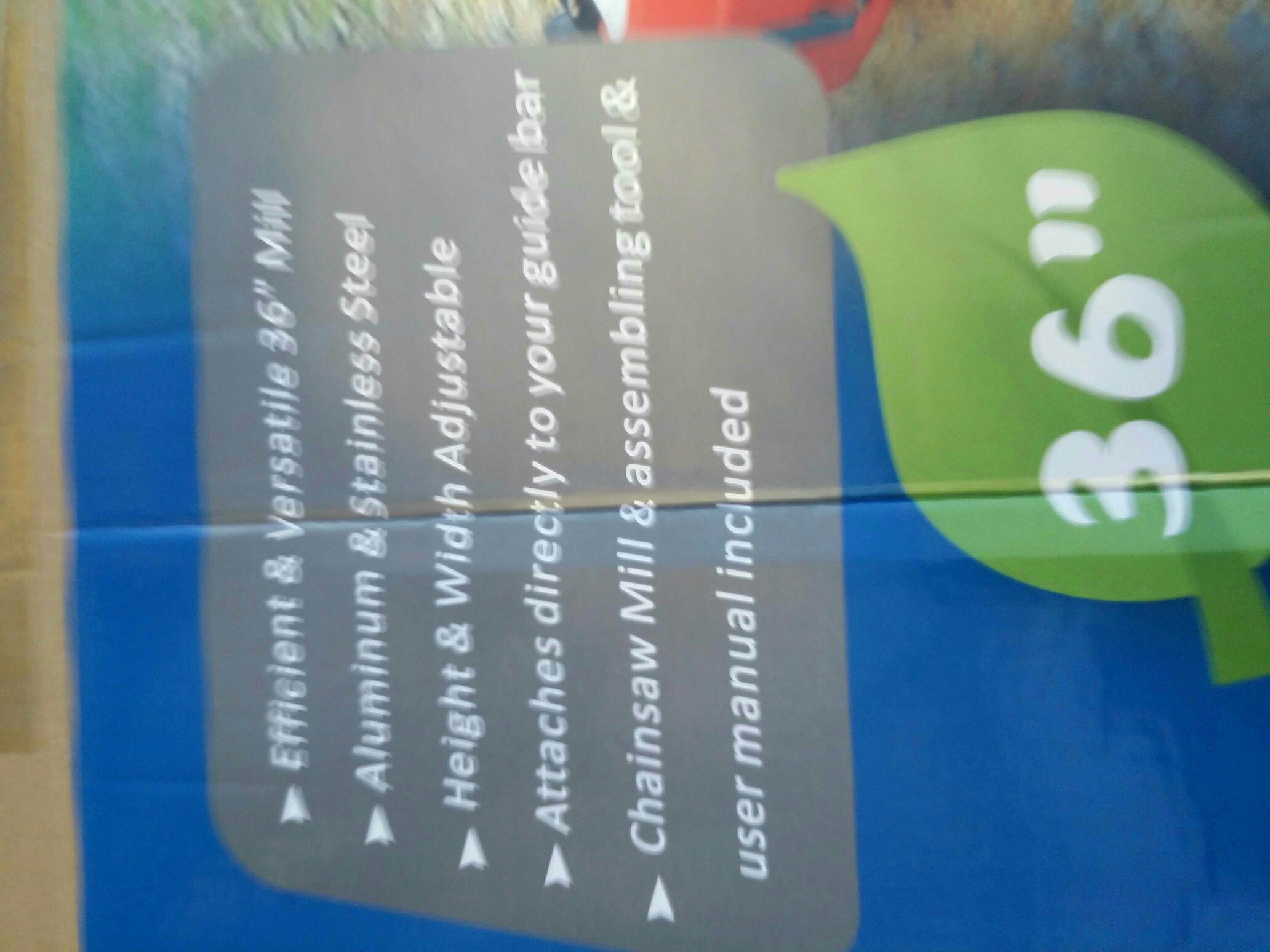

I got this a few days ago and today did an unboxing video, what's in the box. The camera will give you a really good look at each part. Right now you can save a bunch of money on shipping as it is included.

I have a MS660 that I built from a Huztl kit but I want a 070 to be it's permanent buddy. I still need a few other things like the supports and a rail system for the first cut.

The mill is made really well and as I said you can see that for yourself in the video. I look forward to putting it to work in the near future.

I have a MS660 that I built from a Huztl kit but I want a 070 to be it's permanent buddy. I still need a few other things like the supports and a rail system for the first cut.

The mill is made really well and as I said you can see that for yourself in the video. I look forward to putting it to work in the near future.