You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Homelite Chainsaws

- Thread starter briantutt

- Start date

Help Support Arborist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Doesn't get any simpler and works fine in the little Homie tanks. I'm surprised this hasn't already become standard practice on the MiniMacs unless venting in both directions was thought to help minimize their inherent vapor lock issue. If that's the case, use another one on the inside similar to the Homie oil tank setup.This is a mod I'd like to see done and if it works.

Both problems solved.

2broke2ride

Addicted to ArboristSite

- Joined

- Jul 20, 2014

- Messages

- 1,862

- Reaction score

- 2,491

Looks good!I received this powerhead yesterday from @2broke2ride. Very happy with the transaction.

View attachment 851300

Sent from my SM-G950U using Tapatalk

Is there typically some discernible play in the f/w side roller bearing of the larger saws that use them? This XL98 is still haunting me and I'm running out of both magic and patience with it. I've done everything twice on this thing except another vac/pressure test after replacing the old flywheel. Was tight as a drum the first time, but I did have to whack on the crank pretty good to get the old flywheel off. Could possibly have banged some slop into the bearing and created a leak at the seal that's now sucking too much air for the saw to even pop. Thing is, it did fire right off after I got the ignition straightened out initially. Just wouldn't stay running and was fuel starved. Ended up discovering I tore a brand new fuel hose at the tank entry grommet after pulling the whole intake apart to check for problems there first. Hasn't popped since, even with fuel straight into the plug hole. Pulled the flywheel today to see if I somehow overlooked tightening the nut and maybe the key sheared to hose the timing. Was a little too much wiggle in the flywheel for me when I grabbed it and has me wondering where to go next with it. This thing has compression out the rear end, spark you could weld with,, and is pulling fuel, but won't even pop with a plug hole prime on choke. About the only thing I can think of now is a new, very large bottom end air leak. Or I somehow screwed up the reed block putting the intake back together? It does spit a little fuel back through the carb while pulling it over. Figured it was just excess prime, but now I'm wondering a little bit.

Yeah, I could have probably already done another leak test on the damned thing in the time it's taken me to type this. But if I hafta pull that cotter pin on the choke rod one more time i'm gonna scream. Guess I'm hoping for some magical miracle advice instead. Any magicians who walk on water wanna take a stab at it? LOL

Yeah, I could have probably already done another leak test on the damned thing in the time it's taken me to type this. But if I hafta pull that cotter pin on the choke rod one more time i'm gonna scream. Guess I'm hoping for some magical miracle advice instead. Any magicians who walk on water wanna take a stab at it? LOL

Bob Johnson told me to get some play dough or putty put a fuel line down the carb throat and light up a big cigar and blow smoke through the line after sealing it with the putty.Is there typically some discernible play in the f/w side roller bearing of the larger saws that use them? This XL98 is still haunting me and I'm running out of both magic and patience with it. I've done everything twice on this thing except another vac/pressure test after replacing the old flywheel. Was tight as a drum the first time, but I did have to whack on the crank pretty good to get the old flywheel off. Could possibly have banged some slop into the bearing and created a leak at the seal that's now sucking too much air for the saw to even pop. Thing is, it did fire right off after I got the ignition straightened out initially. Just wouldn't stay running and was fuel starved. Ended up discovering I tore a brand new fuel hose at the tank entry grommet after pulling the whole intake apart to check for problems there first. Hasn't popped since, even with fuel straight into the plug hole. Pulled the flywheel today to see if I somehow overlooked tightening the nut and maybe the key sheared to hose the timing. Was a little too much wiggle in the flywheel for me when I grabbed it and has me wondering where to go next with it. This thing has compression out the rear end, spark you could weld with,, and is pulling fuel, but won't even pop with a plug hole prime on choke. About the only thing I can think of now is a new, very large bottom end air leak. Or I somehow screwed up the reed block putting the intake back together? It does spit a little fuel back through the carb while pulling it over. Figured it was just excess prime, but now I'm wondering a little bit.

Yeah, I could have probably already done another leak test on the damned thing in the time it's taken me to type this. But if I hafta pull that cotter pin on the choke rod one more time i'm gonna scream. Guess I'm hoping for some magical miracle advice instead. Any magicians who walk on water wanna take a stab at it? LOL

Rotate the crank slowly while doing this should reveal any major air leaks.

Pretty sound method from what Bob told me.

Spark plug is good, and all wires good?

Freudianfloyd

Clinically Diagnosed with CAD

Got these two Homelites running today. The SXL needed a new fuel line and carb rebuild. The little Super 2 needed seals, fuel and oil lines, carb rebuild and clutch drum bearing. I put way more into the saw than I wanted to, but once I started I was determined to get ut running. Tomorrow I will sharpen the chain.

Any idea what they are worth?

Any idea what they are worth?

Nice work.Got these two Homelites running today. The SXL needed a new fuel line and carb rebuild. The little Super 2 needed seals, fuel and oil lines, carb rebuild and clutch drum bearing. I put way more into the saw than I wanted to, but once I started I was determined to get ut running. Tomorrow I will sharpen the chain.

Any idea what they are worth?

View attachment 851676

Assuming the SXL is not a blue module saw and the mag side looks as good as what’s shown here, easily $100 plus with that good bar.

The Super 2 was more or less their best performing top handle. Unfortunately there’s a zillion of these saws so they aren’t worth all that much. I usually figure 40-60 bucks for a runner in good condition.

If Buckin Billy Ray would start running Homelites, the prices would double to triple like Macs did!

Is there typically some discernible play in the f/w side roller bearing of the larger saws that use them? This XL98 is still haunting me and I'm running out of both magic and patience with it. I've done everything twice on this thing except another vac/pressure test after replacing the old flywheel. Was tight as a drum the first time, but I did have to whack on the crank pretty good to get the old flywheel off. Could possibly have banged some slop into the bearing and created a leak at the seal that's now sucking too much air for the saw to even pop. Thing is, it did fire right off after I got the ignition straightened out initially. Just wouldn't stay running and was fuel starved. Ended up discovering I tore a brand new fuel hose at the tank entry grommet after pulling the whole intake apart to check for problems there first. Hasn't popped since, even with fuel straight into the plug hole. Pulled the flywheel today to see if I somehow overlooked tightening the nut and maybe the key sheared to hose the timing. Was a little too much wiggle in the flywheel for me when I grabbed it and has me wondering where to go next with it. This thing has compression out the rear end, spark you could weld with,, and is pulling fuel, but won't even pop with a plug hole prime on choke. About the only thing I can think of now is a new, very large bottom end air leak. Or I somehow screwed up the reed block putting the intake back together? It does spit a little fuel back through the carb while pulling it over. Figured it was just excess prime, but now I'm wondering a little bit.

Yeah, I could have probably already done another leak test on the damned thing in the time it's taken me to type this. But if I hafta pull that cotter pin on the choke rod one more time i'm gonna scream. Guess I'm hoping for some magical miracle advice instead. Any magicians who walk on water wanna take a stab at it? LOL

None of mine have any discernible play in the crank bearings. Forget the cotter pin and just use a piece of wire long enough to handle easily and cut and bend it a bit once in.

Try a different plug.

If that doesn't work, put it away for a few months and begin again.

That's what I've been doing..., for about a year now. LOL Yesterday was it's August re-visitation day. Fortunately, the owner is a very patient guy and understood this project wouldn't exactly be part of my mainstream activity and could take awhile to get sorted out....put it away for a few months and begin again.

The exhaust port would probably be a pretty big one if not blocked off, too! Bob suggested the same method to me when I was wrestling with the 7-10, but a big wad of bubble gum was his method of choice for sealing the carb that particular day.Rotate the crank slowly while doing this should reveal any major air leaks.

So anyway, and after re-tracing all my steps so far yet one more time, I did end up back at the ignition even though there is a NOS coil, new plug, and killer spark when pulling the plug and grounding it to the muffler. I've heard the stories of plugs firing great when not installed, but not firing "under compression" -- which I personally view as a highly unlikely scenario anyway. Instead, I would suggest a plug lead issue that allows spark when the plug is hanging loose, but loses contact when the plug is installed and or the lead is bent or flexed..., which is actually what I discovered in this latest ghost chase.

I pulled the plug to check for spark once again and I thought I noticed it seemed sort of intermittent. I flexed the lead a little and got no spark. Wiggled it some more and got sporadic results. Finally, zero spark. Boot was as snug as when I installed it so I figured a short or internal break along the lead somewhere. Turns out there were both, sort of. I removed the handle (and that damned cotter pin again to get the carb off!) to inspect the full length of the wire and found a tear in what was a weak spot in the insulation right at the retaining tab in the handle. Figured arcing to ground when the plug was screwed in..., and it probably was to some extent. But in metering for resistance or open between the boot spring connector and the coil, I got nothing. Metering between the boot spring and the tear in the insulation showed intermittent.

Ok. Time to pull the boot, re-install the spring, and seal and tape the lead where it was worn/torn and worry about the bearing next. Turns out the boot end of the plug lead was rotting from the inside out. Looked new from the outside but crumbled when I started pulling the boot. Looked like rusty rubber even though the wire itself is still clean and shiny. Pretty weird, but probably the major reason for my particular "good spark / no spark" problem vs. "plug won't fire under compression".

So now the question becomes how to repair the plug wire. Doesn't want to unscrew and seems to be a molded fit at the coil. A splice seems to be the only solution short of replacing an otherwise new and perfectly good coil. Any secrets to replacing the entire wire? Any splice would need to be done about mid way just to minimize stress and bends at either end. Only other possible option would be to solder the boot spring to the existing bare wire and build the insulation with liquid tape -- which would be pretty redneck and not a course I'd want to take unless it were mine, maybe. And yes, I still have the old coil, but the guy paid for a new one. Got it from Leon, btw. He'd probably make good on a replacement, but gave me such a good price on this one I wouldn't feel right even asking him. The insulation on the old coil is hard as a rock and I'd be gun shy about even trying to get the boot back on at this point anyway.

So there's this month's installment of "As the XL98 Turns". TIA for any more suggestions or further enlightenment. I'll save the bearing for September's episode.

Any idea what they are worth?

Assuming the SXL is not a blue module saw and the mag side looks as good as what’s shown here, easily $100 plus with that good bar.

The Super 2 was more or less their best performing top handle. Unfortunately there’s a zillion of these saws so they aren’t worth all that much. I usually figure 40-60 bucks for a runner in good condition.

Ditto in my area (N. Central Ohio). The dual trigger Super 2's are more desirable and can bring a better price when in good condition.

XL98 Update:

Was provided with no choice but to use the old coil as the plug lead insulation crumbled on the newer one while just testing to see if there was any chance it may actually unscrew to be replaced. Uhhh..., no.

I hope this will be the last (albeit rather brief) installment of the series..., at least for awhile, (or until syndication). Had a nice idle then went south. Carb issues or maybe the bearing heating up and starting to bind a little, or both. At least I have something running (sorta) to go by. Probably just do bearings and seals now and be done with it if the guy wants to spend a couple more bucks to wrap it up right. I sure as hell don't want to see it again after it leaves!

Was provided with no choice but to use the old coil as the plug lead insulation crumbled on the newer one while just testing to see if there was any chance it may actually unscrew to be replaced. Uhhh..., no.

I hope this will be the last (albeit rather brief) installment of the series..., at least for awhile, (or until syndication). Had a nice idle then went south. Carb issues or maybe the bearing heating up and starting to bind a little, or both. At least I have something running (sorta) to go by. Probably just do bearings and seals now and be done with it if the guy wants to spend a couple more bucks to wrap it up right. I sure as hell don't want to see it again after it leaves!

Freudianfloyd

Clinically Diagnosed with CAD

I got number 3 of my Homelites running today. Its ugly, but runs really strong. I honestly didn't expect to get it running at all. The first time I tried to pull it, it felt like it was locked up. After pulling the cover off, I found out it was just caked full of dirt.

I then pulled the carb apart to rebuild it, only to realize it was a Tillotson, and not a Walbro, of course I bouvht two kits assuming it was the same as the saw I fixed up yesterday. Luckily, it was just dirty, but the diaphragms were soft, so I just reused them.

Also had to flip the reed valves over also. Sharpened the chain while it was off and away she went. So far havent spent a dime on it, so Im happy.

I will need to put a new pull rope on it, it broke three times so its only about a foot long at the moment. Luckily the saw starts on half a pull.

I then pulled the carb apart to rebuild it, only to realize it was a Tillotson, and not a Walbro, of course I bouvht two kits assuming it was the same as the saw I fixed up yesterday. Luckily, it was just dirty, but the diaphragms were soft, so I just reused them.

Also had to flip the reed valves over also. Sharpened the chain while it was off and away she went. So far havent spent a dime on it, so Im happy.

I will need to put a new pull rope on it, it broke three times so its only about a foot long at the moment. Luckily the saw starts on half a pull.

I got number 3 of my Homelites running today. Its ugly, but runs really strong. I honestly didn't expect to get it running at all. The first time I tried to pull it, it felt like it was locked up. After pulling the cover off, I found out it was just caked full of dirt.

I then pulled the carb apart to rebuild it, only to realize it was a Tillotson, and not a Walbro, of course I bouvht two kits assuming it was the same as the saw I fixed up yesterday. Luckily, it was just dirty, but the diaphragms were soft, so I just reused them.

Also had to flip the reed valves over also. Sharpened the chain while it was off and away she went. So far havent spent a dime on it, so Im happy.

I will need to put a new pull rope on it, it broke three times so its only about a foot long at the moment. Luckily the saw starts on half a pull.

View attachment 851913

Those plastic air box covers always seem to weather to that chalky appearance. FWIW, a link to a method I use to "restore" the nice black matte finish. Nice saw.

https://houseofhomelite.proboards.com/thread/9628/plastic-restoration-hoggwood-style

Regarding XL-12s and follow-up models--did they all use 12-24 threads for the exhaust? I'm messing with one that has one hole at 1/4" and the other at 5/16". I know 5/16" is wrong, not sure about 1/4".

Freudianfloyd

Clinically Diagnosed with CAD

I decided to give it a try. Worked pretty good. Thanks for the tip.Those plastic air box covers always seem to weather to that chalky appearance. FWIW, a link to a method I use to "restore" the nice black matte finish. Nice saw.

https://houseofhomelite.proboards.com/thread/9628/plastic-restoration-hoggwood-style

2broke2ride

Addicted to ArboristSite

- Joined

- Jul 20, 2014

- Messages

- 1,862

- Reaction score

- 2,491

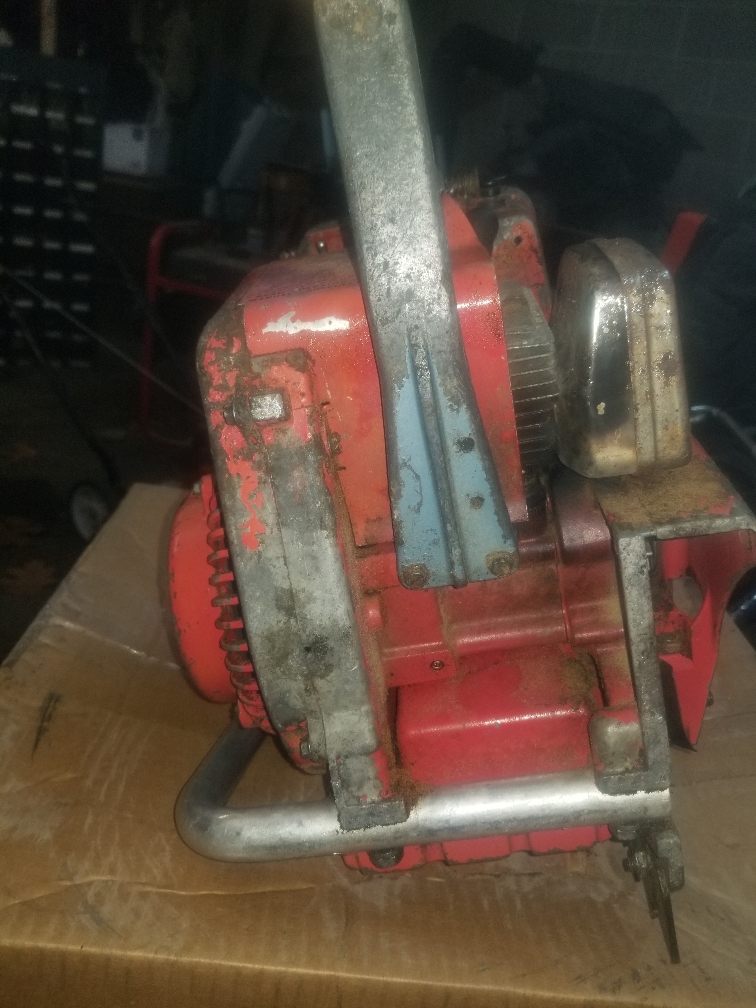

Price drop, $100 plus the ride, someone shoot me an offer.Ok guys, the 925 sold, here's the Next one up for grabs.

C71, not the prettiest saw but it runs and cuts great. Rebuilt carb, new fuel line and filter. Set up for 3/8 chain. Looking for $150 plus the ride but feel free to shoot me offers, I dont get easily insulted lol.

Sent from my SM-G950U using Tapatalk

Sent from my SM-G981U using Tapatalk

Freudianfloyd

Clinically Diagnosed with CAD

I wound up selling this saw yesterday, about 15 minutes after I posted if for sale. For those interested, I listed it for $100 but took $75, as I had nothing in it, and need to make room. I never actually expected to get it running, especially without putting a bunch of money into it so it was a good deal for me.I decided to give it a try. Worked pretty good. Thanks for the tip.

View attachment 852054

That’s very fair for both parties.I wound up selling this saw yesterday, about 15 minutes after I posted if for sale. For those interested, I listed it for $100 but took $75, as I had nothing in it, and need to make room. I never actually expected to get it running, especially without putting a bunch of money into it so it was a good deal for me.

Tried to fix my friend’ XL-2 yesterday. Got it apart and the realized I only had one duckbill left in the shop. And not enough tubing to replumb everything. Ordered another ten pack of duckbills as I have two Super 2’s waiting in the fix pile. It’s always something lol.

Similar threads

- Replies

- 19

- Views

- 953