You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Husky 141 not sucking up gas to the carb ...

- Thread starter woodbutcher80

- Start date

Help Support Arborist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

AKDriveSprocket

ArboristSite Guru

Put a extension on the impulse line and blow and suck on it. The hole in the cylinder may be plugged with carbon.

half_full

ArboristSite Guru

Put a extension on the impulse line and blow and suck on it. The hole in the cylinder may be plugged with carbon.

My thoughts too. Run through the entire impulse passage path. Make sure it's not a gasket blocking the impulse at the intake as well as in the carb.

Just seems odd that two carbs would give you trouble.

woodbutcher80

ArboristSite Member

Make sure it's not a gasket blocking the impulse at the intake as well as in the carb.

Just seems odd that two carbs would give you trouble.

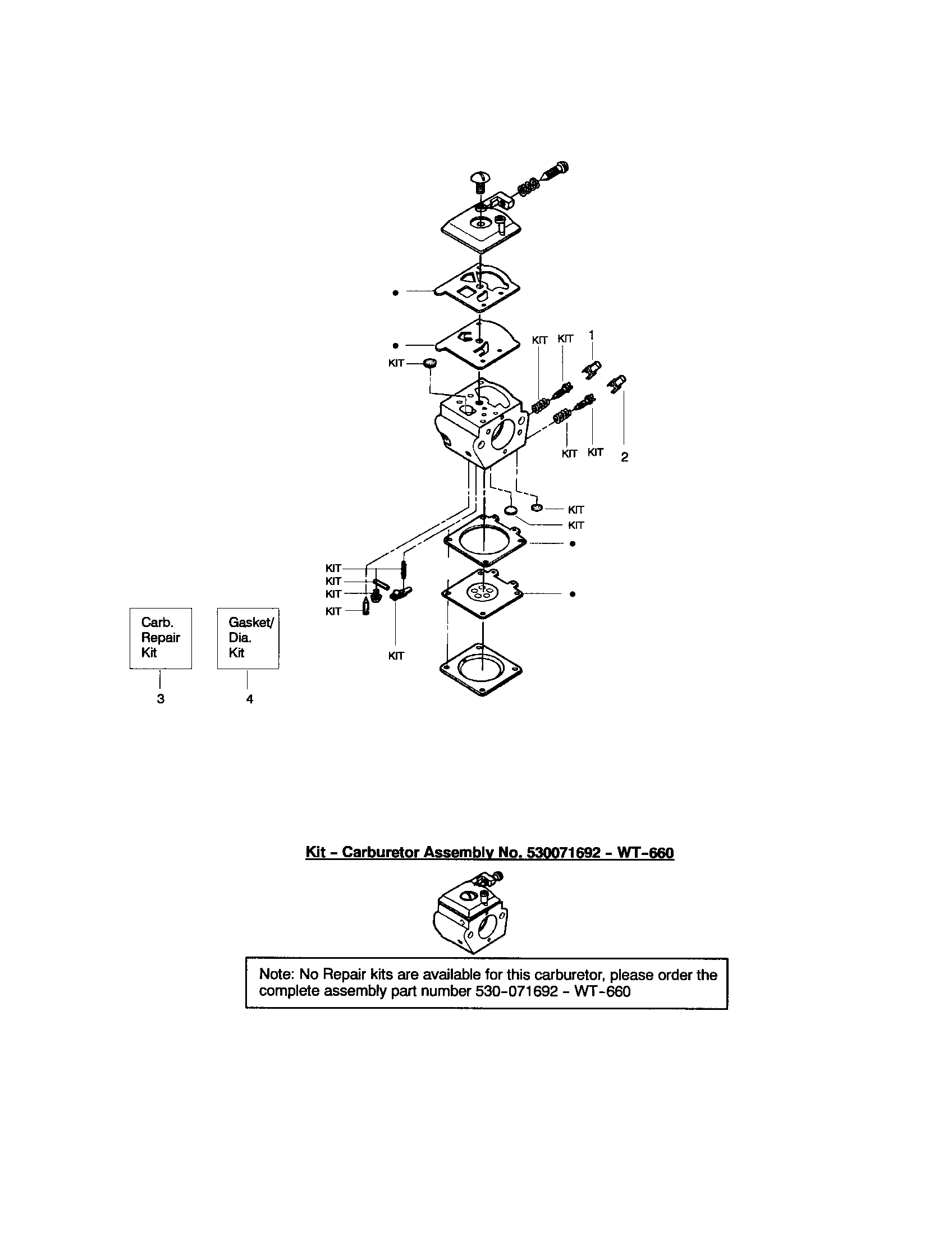

if your talking about the gasket in the pic on post #2, labeled part # 91-72 , intake gasket , i replaced that. the carb has made a good seal on in too as the gasket has the typical 'indented pathway' on it leading to the plastic needle that connects to the rubber impulse tube.

i will pull the carb, and hook one of those pointy plastic pieces that came with my mighty vac on a piece of tubing and blow and suck on it to see what happens. when i look in the impulse hole in the cylinder body , all i see is a metal bar in the middle (probably so the rubber doesnt get sucked into the cyl cavity) , and thats it. ill check it out .

since i have so many saws and small engines and toys, whats a good leak down tester to use?

one time i had a sled that had an few pinhole exhaust manifold leaks that i needed to weld up , and i built a manifold out of pvc pipe , pvc cap and rubber. i drilled a small hole in the plastic cap for a valve stem, pumped her up with a bike pump and sprayed the metal pipe with soapy water... shazaam . found my pinhole leaks. just never thought of applying it to saws...

half_full

ArboristSite Guru

the link below will give you good info. I used the hose from my compression tester (with the schrader valve removed) to hook to a small compressor prior to going with the new mityvac. I still use that setup for finding difficult air leaks.

Note that on the 141 the intake tube has no clamps. If you pressure enough you can push air out around that setup pretty easily

http://www.arboristsite.com/chainsaw/235890.htm#post4314181

Note that on the 141 the intake tube has no clamps. If you pressure enough you can push air out around that setup pretty easily

http://www.arboristsite.com/chainsaw/235890.htm#post4314181

Last edited:

woodbutcher80

ArboristSite Member

i think you gave me a link to get to your house for personal hands-on help with the 141 :msp_tongue:

Jan-Sietze

ArboristSite Operative

And the filters in de carburetor are all clean ?

My 335xpg had the same fault signal, after research showed the filter for vacuum clogged.

My 335xpg had the same fault signal, after research showed the filter for vacuum clogged.

half_full

ArboristSite Guru

i think you gave me a link to get to your house for personal hands-on help with the 141 :msp_tongue:

Hmm, good thing I checked back in. Corrected. But, sure. Bring it on over. Cost of the drive may prohibit but send me a carb and I'll put it on a saw to test it for you and send it back.

woodbutcher80

ArboristSite Member

no filter for vacuum on my carbs. i sprayed cleaner into the corresponding hole the impulse tube pumps on (front face of carb looking at cylinder). it shot out of the hole and out a hole in the top of the carb covered by one of the carb gasket flaps. simple pathway .

woodbutcher80

ArboristSite Member

ok , so heres an update with pics.

i first did a thorough compression test. it wasnt 130 as i thought. its 120psi . after 8 minutes it went to 118psi and thats it. so that is low but should be air tight in regards to the ring.

i hooked my mighty vac to the plastic plate with the nipple that the impulse pipe connects to and the plate was fine, though i saw some soapy water bubbles on the side where the intake gasket rests... so thats ok, just not a perfect seal.

now-as the pictures show below, i connected the mighty vac to the impulse pipe(green guy, and fit snugly) and decided to crank the starter a couple times to see if the pressure needle at least moves from the impulse of the cylinder pressure... it fluttered with every stroke, but the needle never went past maybe 2psi ... hard to tell.

if i took the mighty vac pumper handle off the green rubber pipe and just blew with my mouth into the hose as akdrive suggested air just leaks out of intake boot and somewhere else... im sure the exhaust ... so passage is clear. View attachment 300565View attachment 300566

thats all i got for you so far.

i first did a thorough compression test. it wasnt 130 as i thought. its 120psi . after 8 minutes it went to 118psi and thats it. so that is low but should be air tight in regards to the ring.

i hooked my mighty vac to the plastic plate with the nipple that the impulse pipe connects to and the plate was fine, though i saw some soapy water bubbles on the side where the intake gasket rests... so thats ok, just not a perfect seal.

now-as the pictures show below, i connected the mighty vac to the impulse pipe(green guy, and fit snugly) and decided to crank the starter a couple times to see if the pressure needle at least moves from the impulse of the cylinder pressure... it fluttered with every stroke, but the needle never went past maybe 2psi ... hard to tell.

if i took the mighty vac pumper handle off the green rubber pipe and just blew with my mouth into the hose as akdrive suggested air just leaks out of intake boot and somewhere else... im sure the exhaust ... so passage is clear. View attachment 300565View attachment 300566

thats all i got for you so far.

redunshee

Addicted to ArboristSite

heres a pic of the induction pipe and impulse pipe .. they are on the far left . the induction is the big oval carb boot , and the little sling shot rubber band tube is the impulse line notoious for cracking and causing a lean in the cut problem .

Same setup as my PP325. Did pressure test and it leaked at the small rubber grommet you highlited. Got po'd and ordered grommet, rubber boot and assembly. Surprised that the parts are identical as the PP325 is a Partner 5000 clone.

Bob

Similar threads

- Replies

- 6

- Views

- 501