Mastermind

Work Saw Specialist

Will silver solder take the heat generated? I'm asking because I honestly don't know, not trying to be a smart azz........

Depending on the content it has a melting point between 800 and 1200° F.

Will silver solder take the heat generated? I'm asking because I honestly don't know, not trying to be a smart azz........

Will silver solder take the heat generated? I'm asking because I honestly don't know, not trying to be a smart azz........

I just started using silver solder........amazing how little it takes.

The other advantage over welding rods is you never get confused which one is your leg, and which one is the welding rod. If you wore shoes on occasion it could help avoid a serious injury. Just sayin'

Muh wife bought me some shoes Thank You Very Much. :msp_mad:

Wal Mart branded Crocs don't count. Even if you do fancy the pink ones.

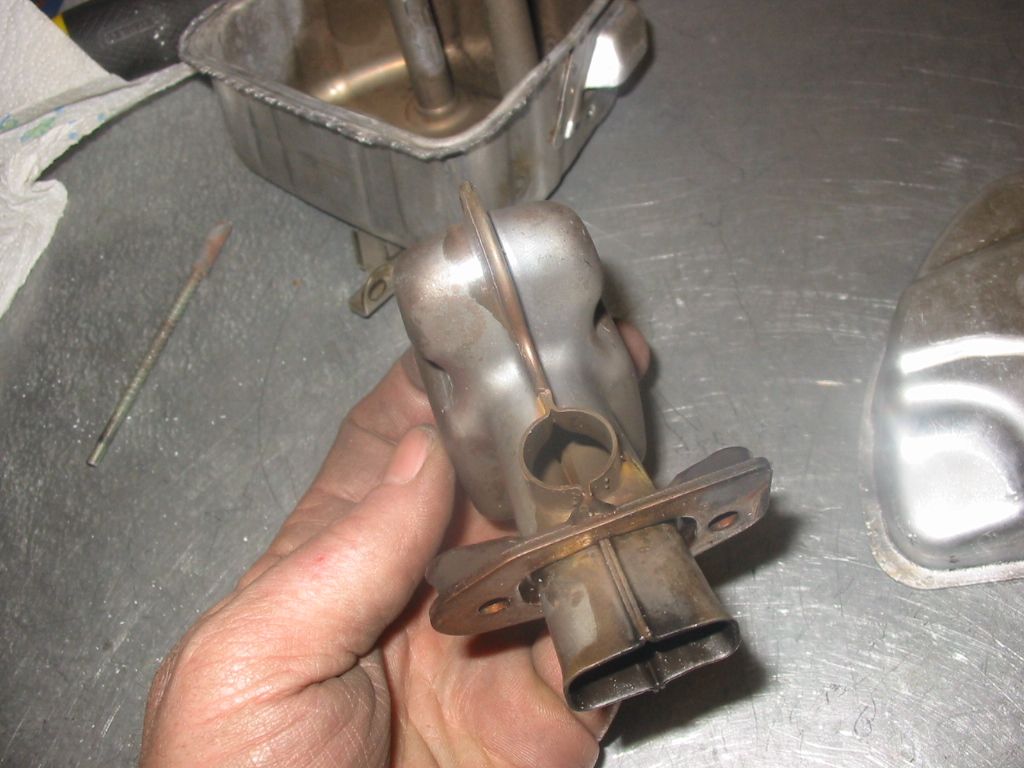

The inside of the muffler.......

I read something about the crank being different in the 7910, do you know what they changed or what is diff?

Well the NEW PS-7910 are selling, and anyone that has bought them or tried them has been HAPPY. As far as NET Weight for Power Head Only as comes in the box here are the results...........

Stock Dry New PS-7900 per our digital UPS Legal scales 14.8 pounds

Stock Dry New PS-7910 per our digital UPS Legal scales 14.8 pounds

Hmmmm same weight, brattier exhaust note, NO CAT, Adjustable Carburator, 15% better on fuel, cleaner running to keep the EPA happy whats not to like??

as far as gross horsepower well I dont have a dyno But in side by side comparison cutting real Logs burring a 24" bar in hardwood 7900 vs 7910 the power and torque are very close!

The EPA Legal saw is still VERY EASY to Service, and do repairs to no major redesign to the saw..., it does have a SLR Muffler, new Cylinder with top side deco, the new lightweight piston same as late model PS-7900's New crank, new coil and a different flywheel. The carb has adjustment screws and a vent hose off the metering pump cover. So again Whats not to Like I ask?????

Both above models are less weight than the CAT equipped PS-6400

Scott

The PS-7910 coil is Limited to 12,800 in lew of the 13,500 on the PS-7900 But like I said side by side stock to stock they are VERY CLOSE I need to test with a broken in saw seeing when we tested them it was a year old 7900 vs out of box 7910. The crank is the same design I believe the timing changed and was told the crank also has been strengthened..

Scott

Enter your email address to join: