[QUOTE="Looks nice Jerry. What bar mount have you got?

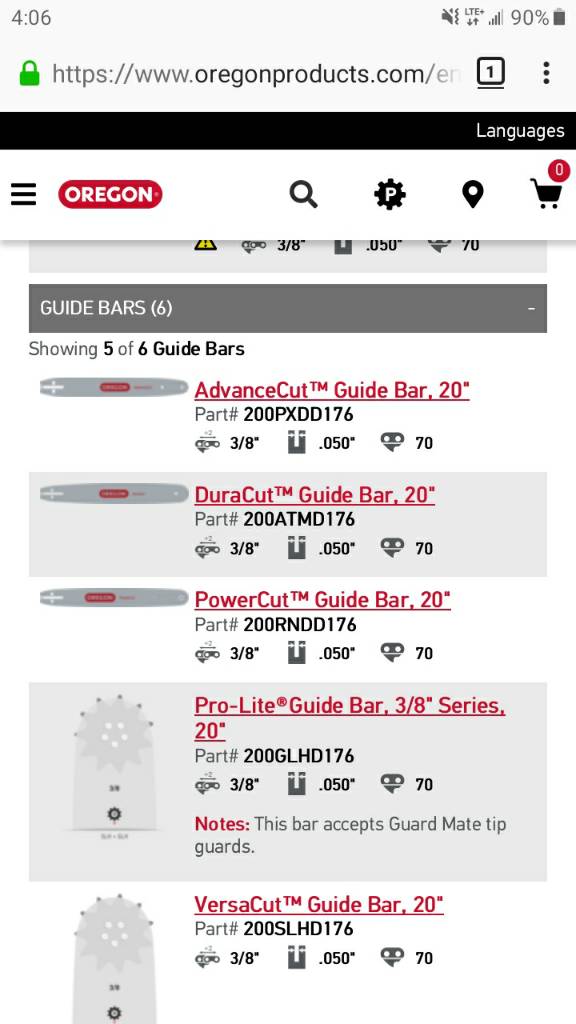

From what I know it's a D176 mount (the bar studs need an 8mm gap in the bar to fit on).

This bar is pretty much what I want - not sure what mount it is - does anybody recognise it and know whether it would fit on the 7-10A (assuming I just want it for my wall and dont care if the oiling holes line up properly etc) / how much effort required to make it fit? I realise I would need a .325 sprocket

https://www.ebay.com.au/itm/NEW-BAR-CHAIN-COMBO-McCULLOCH-20-SPROCKET-NOSE-BAR-325-050-81-LINK-323217-33/172599142155?ssPageName=STRK:MEBIDX:IT&_trksid=p2060353.m1438.l2649

How big are the bar slots on that bar?