You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Measuring Clearances

- Thread starter Vintage Engine Repairs

- Start date

Help Support Arborist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

If you are measuring 1 micron, you need to be in a temperature controled environment with the tool(s) and part temperatures equilibrated.

Most machine shops can't do this.

Most machine shops can't do this.

Canyon Angler

Addicted to ArboristSite

Another issue is, How can you be sure that what you think you're measuring actually is what you're measuring?

Mechanical micrometers are just gear trains, and with enough gear reduction, you could make a micrometer that would measure Angstroms or quarks. You simply reduce the gear ratio such that for every micron of movement, the pointer on the dial spins eleventy-bajillion times.

The bigger issue is, how do you know that you're measuring the width of the paramecium, rather than the length of the paramecium? How do you know how much pressure it takes to crush that microscopic particle of cigarette smoke or pollen on the anvil, without crushing those peaks of metal on the surface of your bearing that are 0.1 micron tall? How much do the faces of your anvil and spindle -- as well as the frame of your micrometer -- bend or deflect under the pressure that you're applying to them when taking your measurement? The instrument might be able to measure such a small distance (assuming that the gears are cut sufficiently well), but can the person using the instrument? When you're getting down into such small units, operator error becomes larger than the distances being measured. Lash in the gear train also becomes an issue. Hell, at 0.1 micron, I suspect Van Der Walls forces become an issue.

I would argue that when you're taking measurements on the order of the diameter of a virus, you have long since given up any hope of measuring accurately by hand with a micrometer.

You can say, "Well, gee, I got the same measurement every time!" But you could "get the same measurement every time" if you held a yardstick at arm's length and measured the diameter of Venus. With a little trig, you could calculate the diameter of Venus to the closest 0.1 micron. But that doesn't mean your calculation would be accurate.

In high-school chemistry, we learned about "significant digits" ... and that figures into this, too, I think...Mad Professor?

Mechanical micrometers are just gear trains, and with enough gear reduction, you could make a micrometer that would measure Angstroms or quarks. You simply reduce the gear ratio such that for every micron of movement, the pointer on the dial spins eleventy-bajillion times.

The bigger issue is, how do you know that you're measuring the width of the paramecium, rather than the length of the paramecium? How do you know how much pressure it takes to crush that microscopic particle of cigarette smoke or pollen on the anvil, without crushing those peaks of metal on the surface of your bearing that are 0.1 micron tall? How much do the faces of your anvil and spindle -- as well as the frame of your micrometer -- bend or deflect under the pressure that you're applying to them when taking your measurement? The instrument might be able to measure such a small distance (assuming that the gears are cut sufficiently well), but can the person using the instrument? When you're getting down into such small units, operator error becomes larger than the distances being measured. Lash in the gear train also becomes an issue. Hell, at 0.1 micron, I suspect Van Der Walls forces become an issue.

I would argue that when you're taking measurements on the order of the diameter of a virus, you have long since given up any hope of measuring accurately by hand with a micrometer.

You can say, "Well, gee, I got the same measurement every time!" But you could "get the same measurement every time" if you held a yardstick at arm's length and measured the diameter of Venus. With a little trig, you could calculate the diameter of Venus to the closest 0.1 micron. But that doesn't mean your calculation would be accurate.

In high-school chemistry, we learned about "significant digits" ... and that figures into this, too, I think...Mad Professor?

There is not much more to say - the results speak for themselves whether you’d like

to believe it or not. The diameter is 20.000, the micrometer is accurate to 2 micron, I’m getting a max deviation of +/- 3 micron in that video, if not right on the money. To say it’s not possible is simply wrong. Better tell Don Bailey his measurements at the 8 minute mark are wrong too.

to believe it or not. The diameter is 20.000, the micrometer is accurate to 2 micron, I’m getting a max deviation of +/- 3 micron in that video, if not right on the money. To say it’s not possible is simply wrong. Better tell Don Bailey his measurements at the 8 minute mark are wrong too.

- Joined

- Jul 19, 2019

- Messages

- 4,240

- Reaction score

- 8,488

Nobody is doubting what your new investment is capable of, but you are not factoring in the human (some call it the idiot) factor and your uncontrolled testing environment.

Simply put, you purchased a piece of equipment more capable than the use you are using it for and the conditions in which you are using it.

Bit like jury rigging a bit of bracketry to an Ikea desk, slapping a crankshaft in it and throwing a dial gauge up alongside to check for runoff- never going to give the same kinds of results as you might see in a proper machinists shop.

You have gotten yourself a new expensive toy, go measure some stuff and be happy.

Simply put, you purchased a piece of equipment more capable than the use you are using it for and the conditions in which you are using it.

Bit like jury rigging a bit of bracketry to an Ikea desk, slapping a crankshaft in it and throwing a dial gauge up alongside to check for runoff- never going to give the same kinds of results as you might see in a proper machinists shop.

You have gotten yourself a new expensive toy, go measure some stuff and be happy.

I dont think the average guy could have steady enough hands to set the micrometer that close.

All the blonde c hairs I felt years ago seemed about the same thickness but then again I wasn t thinking about measuring them at that moment in time.

Kash

Carry on Gaudaost I really enjoy your posts you sure give it your all when you do something.

All the blonde c hairs I felt years ago seemed about the same thickness but then again I wasn t thinking about measuring them at that moment in time.

Kash

Carry on Gaudaost I really enjoy your posts you sure give it your all when you do something.

Chaps, I have nothing against admitting I’m wrong if it is the case, but show me proof or a factual explanation Instead of saying “a micron is so small” “you can’t do that with your skill level” “hand micrometers aren’t accurate” “it’s not possible” even though you have seen me and others do it.

Help me understand how I’m getting the results I am purely by chance, because so far it’s just been your doubt based off of personal opinion rather than facts to back up / disprove what you see.

Help me understand how I’m getting the results I am purely by chance, because so far it’s just been your doubt based off of personal opinion rather than facts to back up / disprove what you see.

- Joined

- Jul 19, 2019

- Messages

- 4,240

- Reaction score

- 8,488

That's about the funniest one yet!

It's published on youtube- it must be Gospel.

Maybe people just get offended by being referred to as something one might wear to protect ones legs from chainsaw cuts, or wear to a gay bar?

I think @Canyon Angler covered the variables quite well above in post # 23- the whole yardstick, bit of trig math and Venus thing.

It's published on youtube- it must be Gospel.

Maybe people just get offended by being referred to as something one might wear to protect ones legs from chainsaw cuts, or wear to a gay bar?

I think @Canyon Angler covered the variables quite well above in post # 23- the whole yardstick, bit of trig math and Venus thing.

Canyon Angler

Addicted to ArboristSite

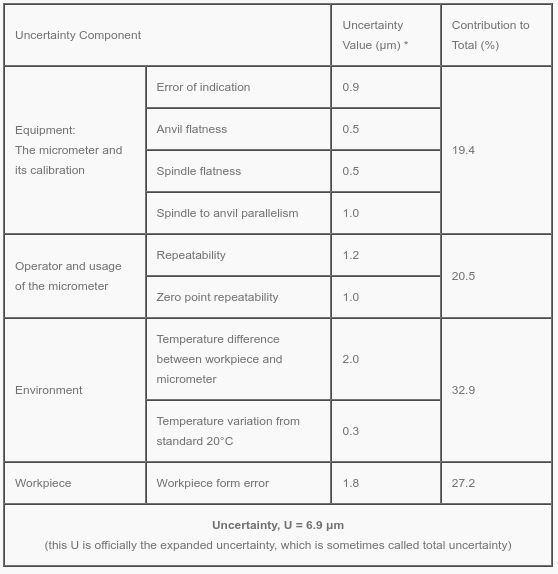

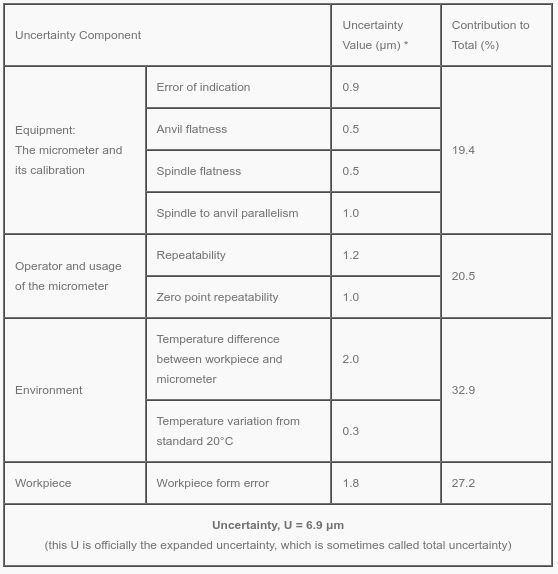

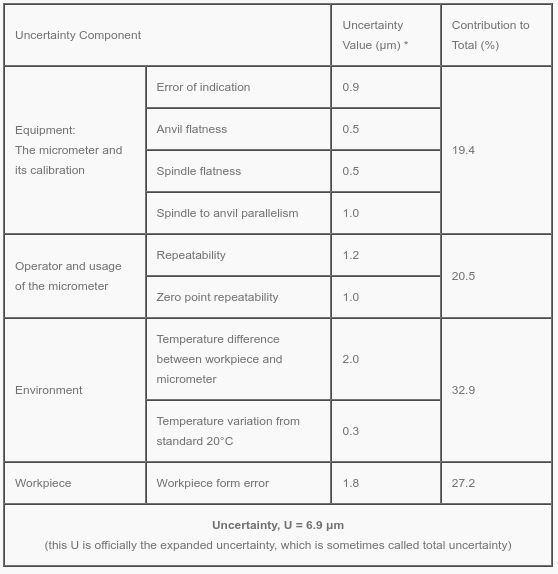

Be certain of the uncertainty.

Here's just one example of an "uncertainty budget" from the Mitutoyo article below (these figures don't apply in all cases, but these are some of the kinds of things we are talking about):

https://www.mmsonline.com/articles/understanding-errors-in-hand-held-measuring-instruments

https://www.mitutoyo.com/news/resource-center/on-measurement-uncertainty/

Tom, maybe you need to bin your fancy new micrometer and get yourself a scanning tunnelling electron microscope. There might be an atom out of place on your bearing race! J/K

J/K

If you really want to get into this kind of thing, I suspect that "understanding the errors, where they come from, and how to minimize them" is more important than the quality of the instrumentation.

There are also some good forums for machinists out there on the web where I'm sure they'd be happy to discuss this kind of topic for weeks on end...best of luck with your new instrument!

Here's just one example of an "uncertainty budget" from the Mitutoyo article below (these figures don't apply in all cases, but these are some of the kinds of things we are talking about):

https://www.mmsonline.com/articles/understanding-errors-in-hand-held-measuring-instruments

https://www.mitutoyo.com/news/resource-center/on-measurement-uncertainty/

Tom, maybe you need to bin your fancy new micrometer and get yourself a scanning tunnelling electron microscope. There might be an atom out of place on your bearing race!

If you really want to get into this kind of thing, I suspect that "understanding the errors, where they come from, and how to minimize them" is more important than the quality of the instrumentation.

There are also some good forums for machinists out there on the web where I'm sure they'd be happy to discuss this kind of topic for weeks on end...best of luck with your new instrument!

You’re a good bloke Crayon, I appreciate chatting with you. I’ll read the links you sent shortly.Be certain of the uncertainty.

Here's just one example of an "uncertainty budget" from the Mitutoyo article below (these figures don't apply in all cases, but these are some of the kinds of things we are talking about):

https://www.mmsonline.com/articles/understanding-errors-in-hand-held-measuring-instruments

https://www.mitutoyo.com/news/resource-center/on-measurement-uncertainty/

Tom, maybe you need to bin your fancy new micrometer and get yourself a scanning tunnelling electron microscope. There might be an atom out of place on your bearing race!J/K

If you really want to get into this kind of thing, I suspect that "understanding the errors, where they come from, and how to minimize them" is more important than the quality of the instrumentation.

There are also some good forums for machinists out there on the web where I'm sure they'd be happy to discuss this kind of topic for weeks on end...best of luck with your new instrument!

I appreciate that Tom strives to do the best he can in his repairs, and teaching himself/learning new skills. He's been a good teacher here.

I really don't like the new digital measuring tools. Too much to go wrong and break. Also, they have dumbed down the people using them (not an insult to Tom). Plus, if you get one wet with water or solvent, or drop it, chance's are much better that it breaks than a mechanical one.

I'll say the same with scales, beam balance vs digital scale. I've seen the restored beam balance used in the 1800s to determine the atomic/molecular mass of hydrogen vs oxygen.

For saws I'm happy for most work with +/- 0.001" 0.025 mm. Verniers do this fine, otherwise I'd use a quality micrometer.

I have 3 calipers: 1) A cheap plastic dial caliper, one I use to tell things like what is the dia of a bolt, 2) a Brown and Sharpe 571 vernier caliper (the most robust), and 3) a Starrett 120 dial vernier (what I usually use). The B + S and Starrett both have nice wooden cases, and are old USA made ones.

There is more that can go wrong (dial parts) with the Starrett, than the B + S, and it is no more accurate despite having a dial.

Starrett 120 - 12

I need reading glasses to use the Brown and Sharpe, but it is the most robust and foolproof (if I do my part), and it has the fine adjustment to "get the feel" correct when taking a measurement, and can then be locked before taking a reading. I like that fine screw adj. better than a wheel on a dial caliper. It has two scales on either side for inner vs outer measurements.

A link showing use of the B + S

Using B + S 571

P.S. I've got ~ $75 into the Starrett and B + S, I got used.

I really don't like the new digital measuring tools. Too much to go wrong and break. Also, they have dumbed down the people using them (not an insult to Tom). Plus, if you get one wet with water or solvent, or drop it, chance's are much better that it breaks than a mechanical one.

I'll say the same with scales, beam balance vs digital scale. I've seen the restored beam balance used in the 1800s to determine the atomic/molecular mass of hydrogen vs oxygen.

For saws I'm happy for most work with +/- 0.001" 0.025 mm. Verniers do this fine, otherwise I'd use a quality micrometer.

I have 3 calipers: 1) A cheap plastic dial caliper, one I use to tell things like what is the dia of a bolt, 2) a Brown and Sharpe 571 vernier caliper (the most robust), and 3) a Starrett 120 dial vernier (what I usually use). The B + S and Starrett both have nice wooden cases, and are old USA made ones.

There is more that can go wrong (dial parts) with the Starrett, than the B + S, and it is no more accurate despite having a dial.

Starrett 120 - 12

I need reading glasses to use the Brown and Sharpe, but it is the most robust and foolproof (if I do my part), and it has the fine adjustment to "get the feel" correct when taking a measurement, and can then be locked before taking a reading. I like that fine screw adj. better than a wheel on a dial caliper. It has two scales on either side for inner vs outer measurements.

A link showing use of the B + S

Using B + S 571

P.S. I've got ~ $75 into the Starrett and B + S, I got used.

Thanks for the kind words, I appreciate you saying so. They are some beautiful tools you have there.I appreciate that Tom strives to do the best he can in his repairs, and teaching himself/learning new skills. He's been a good teacher here.

I really don't like the new digital measuring tools. Too much to go wrong and break. Also, they have dumbed down the people using them (not an insult to Tom). Plus, if you get one wet with water or solvent, or drop it, chance's are much better that it breaks than a mechanical one.

I'll say the same with scales, beam balance vs digital scale. I've seen the restored beam balance used in the 1800s to determine the atomic/molecular mass of hydrogen vs oxygen.

For saws I'm happy for most work with +/- 0.001" 0.025 mm. Verniers do this fine, otherwise I'd use a quality micrometer.

I have 3 calipers: 1) A cheap plastic dial caliper, one I use to tell things like what is the dia of a bolt, 2) a Brown and Sharpe 571 vernier caliper (the most robust), and 3) a Starrett 120 dial vernier (what I usually use). The B + S and Starrett both have nice wooden cases, and are old USA made ones.

There is more that can go wrong (dial parts) with the Starrett, than the B + S, and it is no more accurate despite having a dial.

Starrett 120 - 12

View attachment 905383

I need reading glasses to use the Brown and Sharpe, but it is the most robust and foolproof (if I do my part), and it has the fine adjustment to "get the feel" correct when taking a measurement, and can then be locked before taking a reading. I like that fine screw adj. better than a wheel on a dial caliper. It has two scales on either side for inner vs outer measurements.

View attachment 905384

A link showing use of the B + S

Using B + S 571

P.S. I've got ~ $75 into the Starrett and B + S, I got used.

Same tools, but I took a screenshot for the post, so you could see what I'm talking aboutThanks for the kind words, I appreciate you saying so. They are some beautiful tools you have there.