Lots of it here too, but it does sell for $46 per board footIf you’re interested in milling go for it. But it’s addictive and can be expensive. (You’ve been warned) Nobody makes any money on the very first slabs they mill. You have to learn how to properly mill a log (without screwing it up) to include sealing, stacking and stickering, drying, bar and chain maintenance...etc. if you don’t care about making back your investment on a 661 in a few years then go for it. If you like having extra hardwood for projects then go for it. But don’t thing that tree is going to replace money you need to spend elsewhere in the near future. Cus it ain’t. Around here red oak isn’t worthless but there’s a lot of it so it’s easy to find and not so easy to sell.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Oak down in front yard. Should I try milling?

- Thread starter rumatt

- Start date

Help Support Arborist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

You could also pull a 28" chain/bar with a 461 to use as a CSM.How big a saw ya got? do ya burn wood in the winter? if yes cut it up for firewood. You don't need a 661 to cut that tree with. I cut em bigger than that all the time with my 460 and even the 036. Unless you just have CAD and want a 661. but just remember that you will have that saw for all wood cutting. so if you're cutting smaller trees that bigger saw is overkill. Now if yer a logger then a 661 is not a big saw but I figured you are not since the wanting of advice. A 461 will do that tree with ease and everything else you got.

Nice log(s)

Mill It !!!

Mill It !!!

Lots of it here too, but it does sell for $46 per board foot

Huh? $46 per board foot?

Sent from my iPhone using Tapatalk Pro

Hoodiegadoo

ArboristSite Member

Huh? $46 per board foot?

Sent from my iPhone using Tapatalk Pro

Lol my thoughts exactly. Clearly a typo. Maybe 4-6?

Lol my thoughts exactly. Clearly a typo. Maybe 4-6?

Round here you can get kiln dried s3s for 4$ a board foot. No ones gonna pay that for Air dried CSM lumber.

Sent from my iPhone using Tapatalk Pro

EarlyAcres

ArboristSite Lurker

Ha, good stuff here as I am planning on milling a windfall oak. I found a used MS660 and I’ll build a CSM since I have welder. Ya gotta start somewhere......Round here you can get kiln dried s3s for 4$ a board foot. No ones gonna pay that for Air dried CSM lumber.

Sent from my iPhone using Tapatalk Pro

Ha, good stuff here as I am planning on milling a windfall oak. I found a used MS660 and I’ll build a CSM since I have welder. Ya gotta start somewhere......

Don't get me wrong I'll mill just about anything. I love it. Just don't expect to make a bunch of money with a CSM.

Sent from my iPhone using Tapatalk Pro

EarlyAcres

ArboristSite Lurker

No illusions here about making money. I thought hobbies were for spending it.....Don't get me wrong I'll mill just about anything. I love it. Just don't expect to make a bunch of money with a CSM.

Sent from my iPhone using Tapatalk Pro

Sourwould

ArboristSite Operative

If you don't want to just burn it, red oak makes good shake siding/roofing. Firewood shed.

No illusions here about making money. I thought hobbies were for spending it.....

CSM just get you hooked. Then it's bandsaw mills, forklifts, trailers, winches, peavies.

Nothing better than pulling that first 4/4 board off the bandsaw mill.

Sent from my iPhone using Tapatalk Pro

rumatt

ArboristSite Operative

Thanks everyone! I am definitely not that excited to mill just for the sake of it. I don't do wood projects, so it seems this tree is worth more to me as firewood than anything else.

I currently have a 50cc Stihl 261cm and thats what I used to cut the top of the tree. I could finish the tree with it if I had to, but I like toys so I was ready to buy a 461. But I also like technology (M-tronic) and anti-vibe for my wrists, so I was debating either the 441cm... or a 661cm if I was going to mil.

So now I'm back to 441cm, or wait for the saw I really want: 462cm!

I currently have a 50cc Stihl 261cm and thats what I used to cut the top of the tree. I could finish the tree with it if I had to, but I like toys so I was ready to buy a 461. But I also like technology (M-tronic) and anti-vibe for my wrists, so I was debating either the 441cm... or a 661cm if I was going to mil.

So now I'm back to 441cm, or wait for the saw I really want: 462cm!

I think that s the cheapest thing to doYeah, I've been googling and finding a lot of folks saying they can't make much money, if any at all. Wood is pretty expensive to buy, so I'm surprised.

If I'm just going to end up giving away the slabs, I'd rather split it and store it for firewood.

Unless you’re going to build something with it then I say firewood. But then again there’s a lot of red oak getting hit with disease at least in the south so who knows?

In my avatar the 60" cannon bar is mounted on ms-460. Only muff modded with max flo air filter. Square chisel skip chain to halve the power required and clear chips better. In my area, the BS millers almost all are limited to 24" max cut. Wood working peeps see my wide slabs and stop to inquire as some are stickered out front, and visible from the two laner . I started from the enjoyment I got with a 170 mounted on the equivalent of aTM-56 making up to 6" square posts.Thanks everyone! I am definitely not that excited to mill just for the sake of it. I don't do wood projects, so it seems this tree is worth more to me as firewood than anything else.

I currently have a 50cc Stihl 261cm and thats what I used to cut the top of the tree. I could finish the tree with it if I had to, but I like toys so I was ready to buy a 461. But I also like technology (M-tronic) and anti-vibe for my wrists, so I was debating either the 441cm... or a 661cm if I was going to mil.

So now I'm back to 441cm, or wait for the saw I really want: 462cm!

If it was me the first slice wood be sealed to make a bench seat. Then the next two slices wood book match with the pith lost from between. The chunk of wood in between can be firewood. Those two live edge slabs from the center may stir creative juices in hobby wood workers. That is what happens for me when they find that size is available.

On the other hand, if that was white oak the log wood be transported to the nearest stave ( as in barrel) maker if I remember the cut off stump is $1.50 bf when greater than 14" diameter, bark included.

Just saying that logs don't have to be all one use. Either this or that, and 70 cc saws can be used on large cuts with sharp cutters and correct depth guages set.

If you choose to try and don't like the results, used milling equipment can bring back more than half the original expenses while the experience is priceless while you had good reason to buy & keep that saw. Woodn't want to take a loss on a powerhead that is just getting broke in ya know.

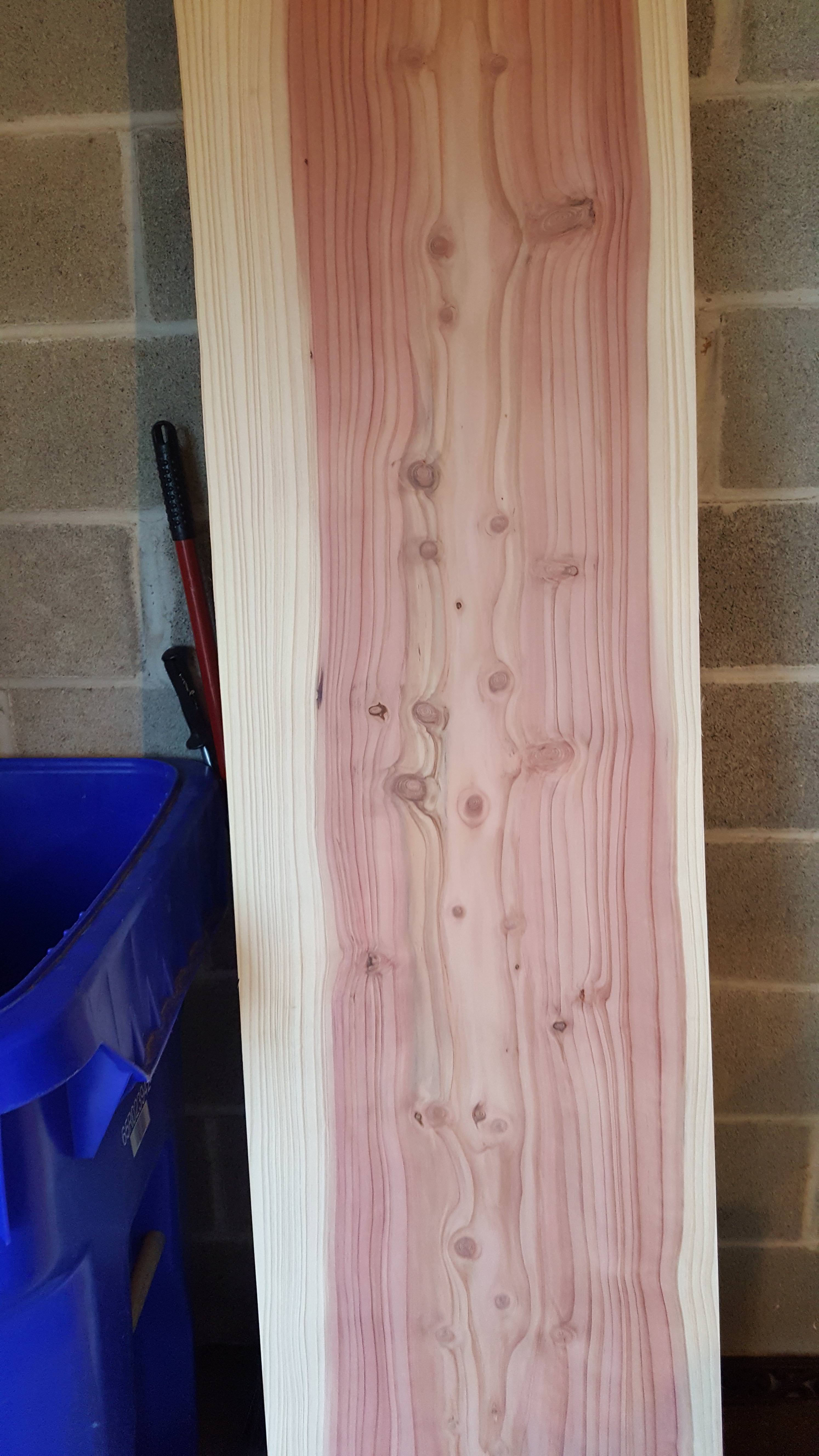

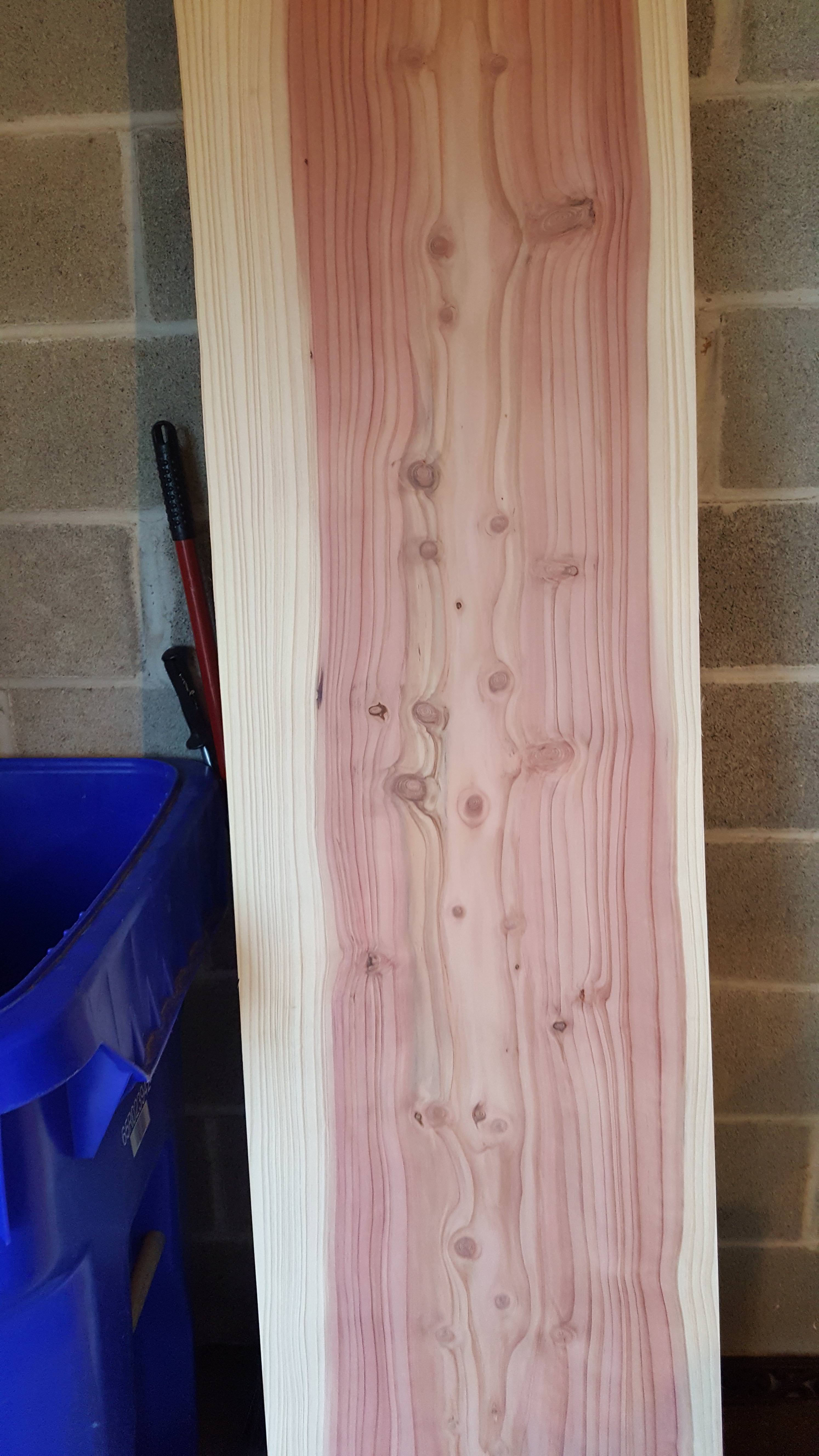

This is 38" wide, cut on a Friday, whole log

This is 38" wide, cut on a Friday, whole log Live edge slabbed and stickered by Monday. Four cars stopped and asked about the" large boards" with two indicating they're coming back.

Here is an eleven foot bench, red oak.

Here is an eleven foot bench, red oak.Wow, I've been so busy I haven't checked in over here in a couple weeks. That is a pretty log. I like Red Oak for milling. I made a bench for my fire pit with an 8 footer, and two mantels for a friend. If I had the bench planed and smoothed to the ends I'd ask $400 for it. In the rough like it is I'd take $200. The mantels came out pretty nice, and both pieces came from the same slab. They used bar top epoxy to coat them. They are trying to keep the bark on. The slabs are 2-3 years old and the bark is just starting to come loose on the bench. All the slabs from that log that are under the shed, the bark is still holding tight. Is it worth it money wise, I don't know. Most of the stuff I make I wind up giving to friends or selling to friends cheap. I used oblong crotch pieces for the legs of the bench. That way they were wider than the seat and made cup holders in the corners. On the two mantles mounted on the fireplace you have to look close to see the top piece. The shot is so straight on it looks like part of the stone.Here's a couple pics.

This is a Dawn Redwood mantle I sold to a friend for his daughters house. I charged him $100 for it.

These are the two mantles after I planed them. The mill did such a nice job it only took 3 passes through the planer on each side to get all of the saw marks out.

I'd cut the log in sections the length that I needed. Since all of my stuff is live edge, and I'm not going for the best quarter sawn grain patterns, I'd roll the log so that crack is parallel to the mill. The log looks straight enough that the crack will all be in the center board, then you can snap a chalk line on it and cut the pith out and have two pieces like the manltes I did above. The mantles above came from the same slab, I snapped a chalk line on them and cut the straight edge with my DeWalt 18 volt circular saw. They were a little over 2" thick and the DeWalt had no problem trimming them.im an extreme greenhorn to CS milling, but it sure looks like theres a heckuva crack at the topcut that could have happened when the tree fell- a crack that could run a ways down the log.

Similar threads

- Replies

- 27

- Views

- 3K

- Replies

- 18

- Views

- 1K

- Replies

- 88

- Views

- 7K

- Replies

- 19

- Views

- 2K

Latest posts

-

-

-

Want to Sell Parts for Husqvarna, Homelite, Stihl, Dolmar, Walbro, craftsman….

- Latest: Chainsaw Collectors

-

-

-

-