Since it's a non safety chain from a 18" LP bar I'd say it's a great candidate to shorten.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Philbert's Chain Salvage Challenge

- Thread starter Philbert

- Start date

Help Support Arborist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

That Wood Grind!

Philbert

Philbert

ChoppyChoppy

Tree Freak

If you want to cover the ~$18 shipping I'll mail you a big flat rate of old loops. They are likely going in the dumpster otherwise. Have 4 or 5 pails full.

Sort them by size and offer them in the Xmas giving thread (even in May)!

Guys might make better use of a box of, say .325 chain, or narrow kerf, then a box of random sizes.

Philbert

Guys might make better use of a box of, say .325 chain, or narrow kerf, then a box of random sizes.

Philbert

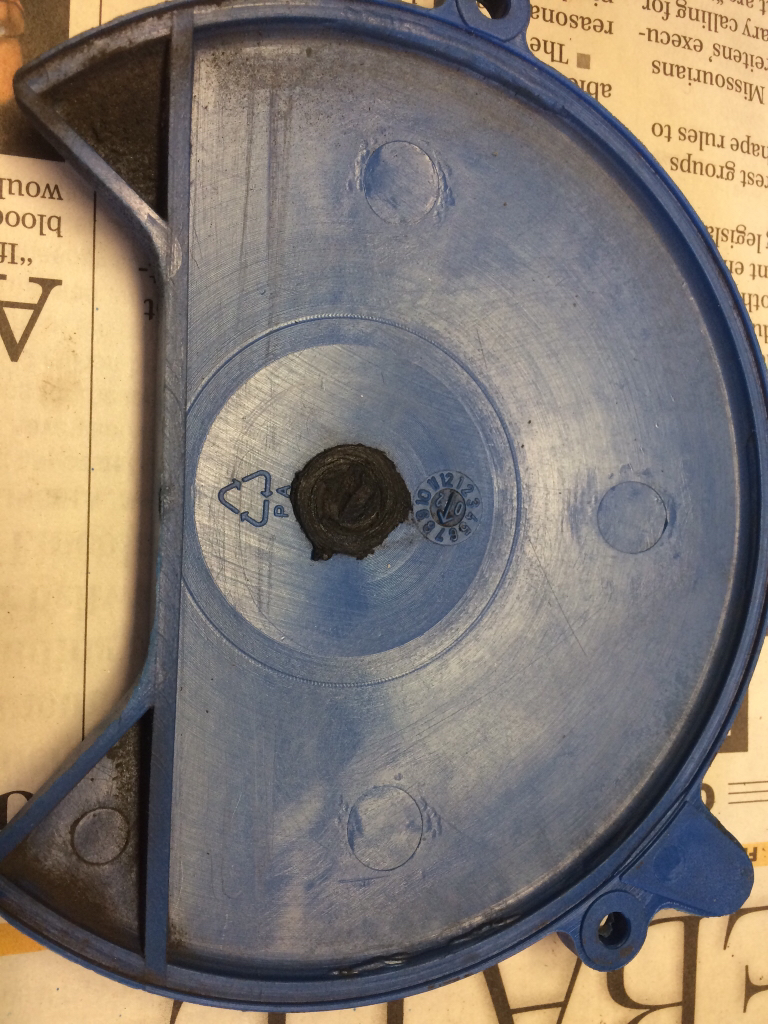

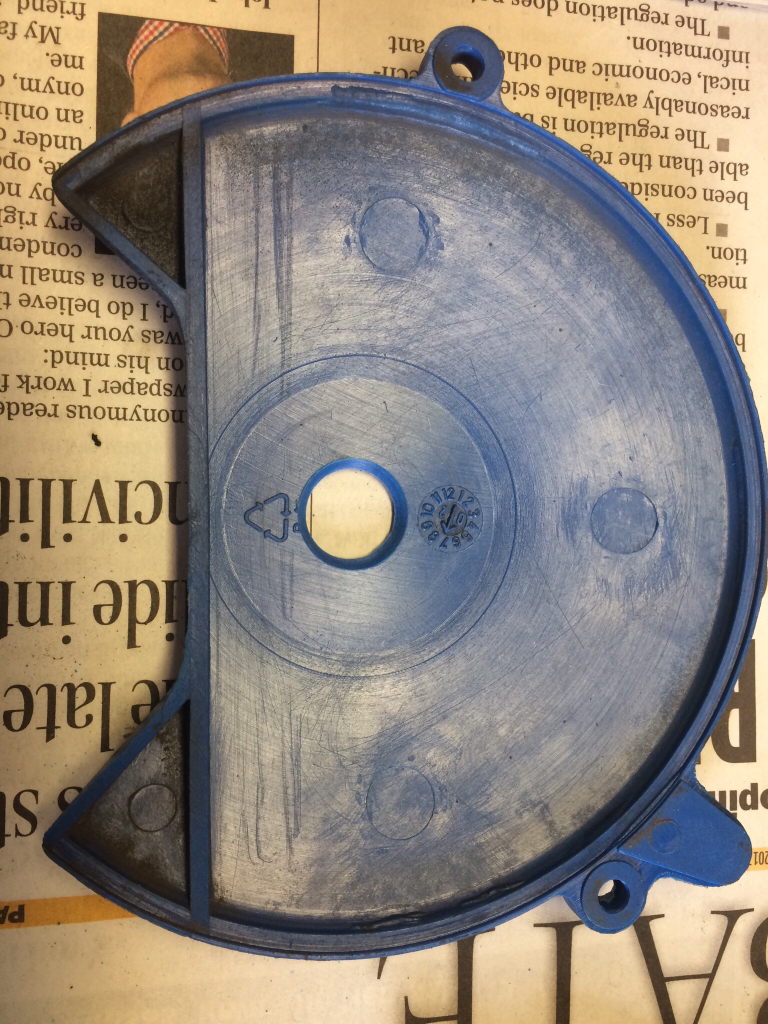

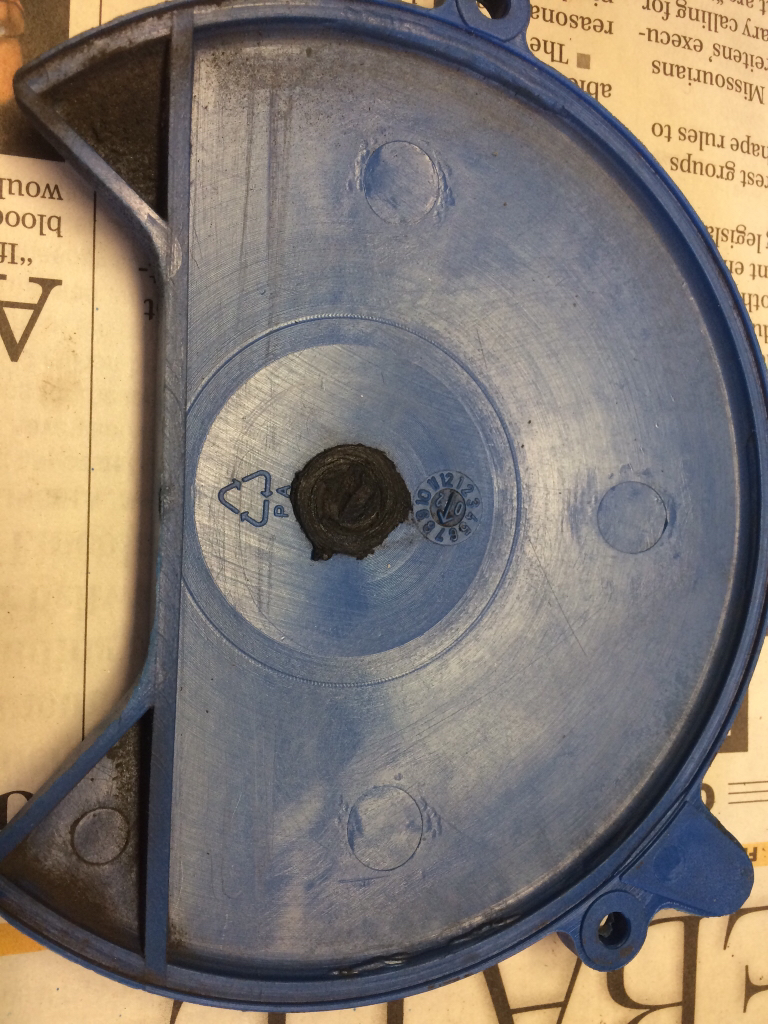

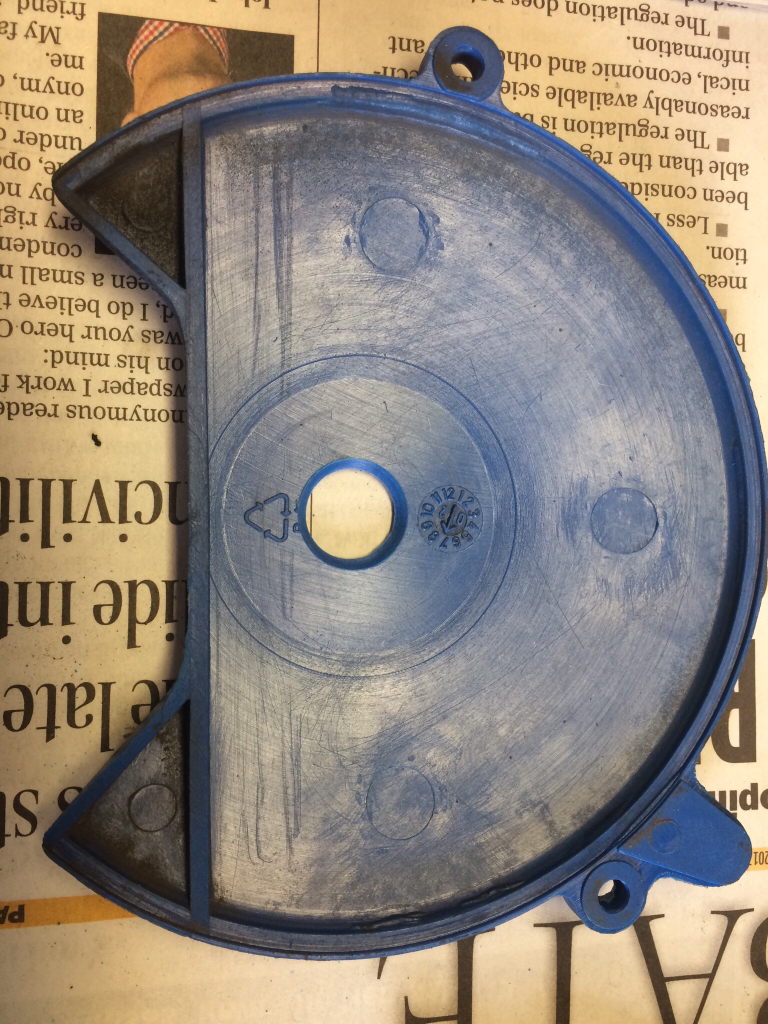

My 'Nick the Grinder' had a problem.

Seems something caused it to spin weld the motor end to the wheel guard.

I can feel no play radial or axiel to cause it.

So, drilled a clearence hole to prevent a reocurrence.

Seems something caused it to spin weld the motor end to the wheel guard.

I can feel no play radial or axiel to cause it.

So, drilled a clearence hole to prevent a reocurrence.

Been a While . . .

I continue to scrounge, salvage, and save chains, but have not been reporting on it much. Not very interesting when the same story repeats itself. But I will try to post a few, newer case studies.

Challenge Chain # 24(?)

Received a chain from 'a friend', who got it from his 'friend', who basically said the chain was 'cursed'; he had tried everything, but the chain still would not cut.

First step is a good cleaning to see what we have.

Did not look like a chain from Hell, but inspected it closely due to the comments which accompanied it.

Two things were noticeable:

1. Although both the top plate and side plate edges were sharp, the leading corner (or 'point') was damaged on all of the right side cutters. This is important on full-chisel chains, which lead with the corner. This damage essentially created a tiny bevel to push the cutter away from the wood, rather than lead the cutter into the cut.

2. One of the 'friends' had apparently dropped the depth gauges successively lower attempting to make 'the-chain-that-won't-cut' cut. I measured offsets of .035" to .040" using a feeler gauge. But, by fling the depth gauges flat, this person created new, sharp corners at the front of each depth gauge, which could dig into the wood when the cutter tips back, creating excessive drag.

I put the cleaned chain on a grinder, and evened up all of the cutters, taking them back, just past the damaged corners. I went back with the ScotchBrite wheels (see Post #284) and rounded over each depth gauge to something closer to the factory profile (I did not want to take them any lower, or make them any lower than the low-kickback bumpers).

Reconditioned chain is on top. Bottom is a section of the 'before' chain (I shortened the original loop to fit a smaller bar). The differences are small, if you are not looking for the details. My 'friend' says that the reconditioned loop of the-chain-that-won't-cut 'works great', and 'cuts awesome in softwood'. I did not test it before, or after, so I have to take his word.

WINNER? Philbert! (and his 'friend').

LESSONS? Details matter: the leading point is important on full-chisel chains, and manufacturers recommend rounding over depth gauges to factory profiles for a reason.

I continue to scrounge, salvage, and save chains, but have not been reporting on it much. Not very interesting when the same story repeats itself. But I will try to post a few, newer case studies.

Challenge Chain # 24(?)

Received a chain from 'a friend', who got it from his 'friend', who basically said the chain was 'cursed'; he had tried everything, but the chain still would not cut.

First step is a good cleaning to see what we have.

Did not look like a chain from Hell, but inspected it closely due to the comments which accompanied it.

Two things were noticeable:

1. Although both the top plate and side plate edges were sharp, the leading corner (or 'point') was damaged on all of the right side cutters. This is important on full-chisel chains, which lead with the corner. This damage essentially created a tiny bevel to push the cutter away from the wood, rather than lead the cutter into the cut.

2. One of the 'friends' had apparently dropped the depth gauges successively lower attempting to make 'the-chain-that-won't-cut' cut. I measured offsets of .035" to .040" using a feeler gauge. But, by fling the depth gauges flat, this person created new, sharp corners at the front of each depth gauge, which could dig into the wood when the cutter tips back, creating excessive drag.

I put the cleaned chain on a grinder, and evened up all of the cutters, taking them back, just past the damaged corners. I went back with the ScotchBrite wheels (see Post #284) and rounded over each depth gauge to something closer to the factory profile (I did not want to take them any lower, or make them any lower than the low-kickback bumpers).

Reconditioned chain is on top. Bottom is a section of the 'before' chain (I shortened the original loop to fit a smaller bar). The differences are small, if you are not looking for the details. My 'friend' says that the reconditioned loop of the-chain-that-won't-cut 'works great', and 'cuts awesome in softwood'. I did not test it before, or after, so I have to take his word.

WINNER? Philbert! (and his 'friend').

LESSONS? Details matter: the leading point is important on full-chisel chains, and manufacturers recommend rounding over depth gauges to factory profiles for a reason.

Here's one for you, Philbert. I seem to recall seeing a chain like this somewhere before..., maybe even earlier in this thread? It's on a Homelite 1050A I acquired a few years ago that I recently pulled out to go over and hopefully get running. Got it running, but it sure wasn't gonna cut anything with this chain. Obviously got into something mighty abrasive to create such an even bevel on both sides. All the cutters are the same. What surprises me are the rakers don't show more unusual wear or deformity. The rounding of the rear corner opposite the working corner also seems a little unusual..., unless of course this chain is supposed to look this way! An awful lot of material will need to be removed to make it a 'normal' chain again.

LegDeLimber

Addicted to ArboristSite

My guess would be the motor shaft is magnetized and the grinding cruft is accumulating there.My 'Nick the Grinder' had a problem.

Seems something caused it to spin weld the motor end to the wheel guard.

Add a bit of static charge while spinning and could be when it gets started?

Yes. See post #353, above. You would have to grind past the damage.I seem to recall seeing a chain like this somewhere before..., maybe even earlier in this thread? . . . got into something mighty abrasive to create such an even bevel on both sides. . . .An awful lot of material will need to be removed to make it a 'normal' chain again.

Philbert

Finnrpm

ArboristSite Operative

Here's one for you, Philbert. I seem to recall seeing a chain like this somewhere before..., maybe even earlier in this thread? It's on a Homelite 1050A I acquired a few years ago that I recently pulled out to go over and hopefully get running. Got it running, but it sure wasn't gonna cut anything with this chain. Obviously got into something mighty abrasive to create such an even bevel on both sides. All the cutters are the same. What surprises me are the rakers don't show more unusual wear or deformity. The rounding of the rear corner opposite the working corner also seems a little unusual..., unless of course this chain is supposed to look this way! An awful lot of material will need to be removed to make it a 'normal' chain again.

Powersharp been used on standard chain, if " sharpening " is continued, it will make top plate so thin it will break when trying to make a cut.......

Bought saw from local craigslist while back and it had two chains, one without top plates and one with thin ones!!!! Seller offered powersharp with the saw and said " this is really good sharpener!!"

Just replied " I file my chains, you can keep it!!"

RV

D

Deleted member 149229

Guest

Bought saw from local craigslist while back and it had two chains, one without top plates and one with thin ones!!!! Seller offered powersharp with the saw and said " this is really good sharpener!!"

Just replied " I file my chains, you can keep it!!"

Only been into saws a couple years but was a machinist my whole life. First time I saw a Powersharp my initial reaction was "You have to be sh****ng me." That invention rates right up there with the Pet Rock, rap music and lite beer.

PowerSharp chains are covered in other threads - I'd like to keep this one on salvaging chains, unless of course, it is salvaging a PowerSharp chain!

Thanks.

Philbert

http://www.arboristsite.com/community/threads/oregon-powersharp.125402/

http://www.arboristsite.com/community/threads/powersharp.148391/

http://www.arboristsite.com/community/threads/oregon-power-sharp-any-good.211415/

http://www.arboristsite.com/community/threads/the-power-sharp-system.159381/

http://www.arboristsite.com/community/threads/setting-rakers-on-powersharp-chains.292028/

Thanks.

Philbert

http://www.arboristsite.com/community/threads/oregon-powersharp.125402/

http://www.arboristsite.com/community/threads/powersharp.148391/

http://www.arboristsite.com/community/threads/oregon-power-sharp-any-good.211415/

http://www.arboristsite.com/community/threads/the-power-sharp-system.159381/

http://www.arboristsite.com/community/threads/setting-rakers-on-powersharp-chains.292028/

Just the 3/8" LP salvaged out of two 40# flat rate boxes of chain from Valleyfirewood. Forty loops.[emoji15]

I was very picky.

Phil would squeal at what I tossed in the junk.

I was very picky.

Phil would squeal at what I tossed in the junk.

I could have tossed out a stretched chain for a Stihl MS460 today with a 28" bar. It had 91 drive links on board, exactly what Stihl and the bar itself recommends. Unfortunately, it could not be tightened. This chain was not even half used up. But, the chain tensioner was all the way out and the chain was still too loose. I elected to remove a drive link and install the chain again. That worked and I salvaged the chain.

The saw owner wanted two more chains. I tried making a chain with 90 drive links of new chain, but it could not be installed. So I added one more drive link and then made the second one also with 91 DL's. Both looked very good and tightened up nicely. I have to wonder how many 91 DL chains on Stihl MS460 saws with 28" bars cannot be tightened after they get used awhile. They can be salvaged, but you have to knock off a drive link.

Seems like Stihl might have made a small design blunder here, but I hate to be critical.

The saw owner wanted two more chains. I tried making a chain with 90 drive links of new chain, but it could not be installed. So I added one more drive link and then made the second one also with 91 DL's. Both looked very good and tightened up nicely. I have to wonder how many 91 DL chains on Stihl MS460 saws with 28" bars cannot be tightened after they get used awhile. They can be salvaged, but you have to knock off a drive link.

Seems like Stihl might have made a small design blunder here, but I hate to be critical.

'Squeal!'Just the 3/8" LP salvaged out of two 40# flat rate boxes of chain from Valleyfirewood. . . . Phil would squeal at what I tossed in the junk.

(Mail me the rejects )

Phbert

I think Philbert would squeal even louder if he knew I threw away a good sharp chain with 91 drive links on board for an MS 460 with a 28" bar that could not be tightened. So, I refused to do it and saved the chain by knocking out one DL. Considering how many Stihl MS 460s have been sold with 28" bars, you have to wonder how many used but usable chains have been tossed out because they are too loose and cannot be tensioned by this saw.'Squeal!'

(Mail me the rejects )

Phbert

Frankly, I was surprised and now I'm squealing.

'Squeal!'

(Mail me the rejects )

Phbert

No.

I will not be an enabler and feed your OCD.[emoji56]

Your Wife/S.O. will thank me.

[emoji48]

I do however have a challenge worthy of the most proficient chain restorer.

9/16" x .080" x 56 dl loop on my gear drive Remington. Needs a lot of the cutters replaced. I have a pile of Remy/Mall repair kits.

Looks like it was filed on by a crazy person with a way undersized file.[emoji849]

9/16" x .080" x 56 dl loop on my gear drive Remington. Needs a lot of the cutters replaced. I have a pile of Remy/Mall repair kits.

Looks like it was filed on by a crazy person with a way undersized file.[emoji849]

Similar threads

- Replies

- 1

- Views

- 126

Latest posts

-

So question of the day did poulan ever make any good reliable chainsaws or weedeaters etc

- Latest: RedneckChainsawRepair

-

-

-

Scrounging Firewood (and other stuff)

- Latest: SS396driver

-

-

-

-