project is going good. i need walboro carb now to replace the zama. i cant get tuned, ive been through two zama carbs cleaning them out the best i know how, complete carb tear downs and putback together. both carbs been sitn for many years. neither carb brings the H side in.

044 has the stock cylinder on it now, i lucked out and got a 044 10mm with a sharp top end pushn 165lb of compression. so now ive got stock top end and ported one, ill swap to ported one ounce i get it running like it should

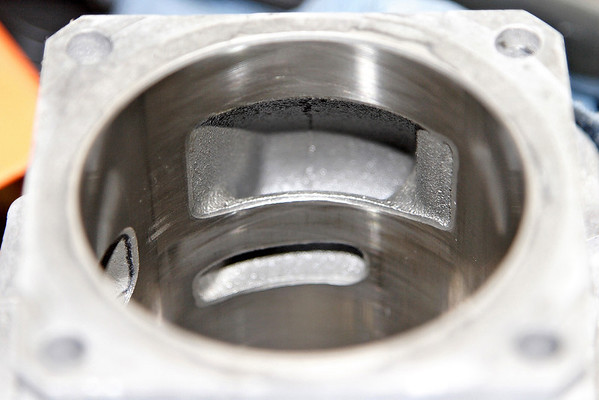

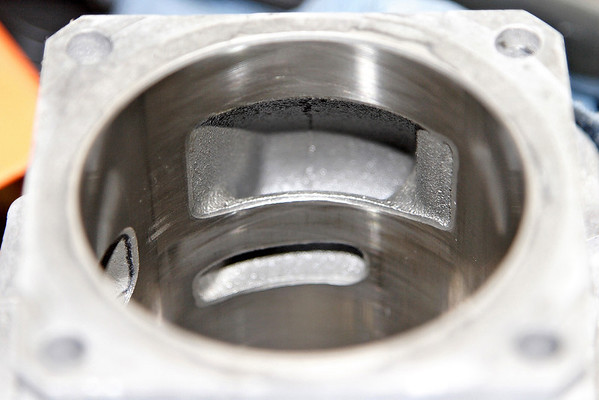

084 is comeing along though im not done porting and the piston showed up yesterday, the 084 still needs the exhaust widend and do some chamfering, probly work on he piston windows just enough to knock down the casting lines. and blen from the inside out alittle bit.

i also use a flat file to knock the exhaust port flat. another thing ive found is the 3/8 chain file grinder for the power grinders works very well in the dremel, its kinda like a long rasp to knock the ports nice and flat before useing the hand file.

ive learned alot in the last few months . enough so the 359 is nagging port me again you know theres more gains to be had.

but im in the bad time of the year for projects this week ive been wokn 6:30am to 8;30pm. im bout tired of it already but i guess i gotta start makn up for not workn much at all over the winter. so you guys wont be putn up with me quite as often as you used to have to.

anyways im off to work for hopefully a nice easy early off day. no one should have to work close to 70hrs in 5 days

thanks

Evan